Synthetic method of mesoporous-microporous composite ZSM-5/MCM-41 molecular sieve

A technology of MCM-41 and ZSM-5, applied in the field of synthesis of microporous-mesoporous composite ZSM-5/MCM-41 molecular sieve, can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (a) Alkaline treatment of ZSM-5 molecular sieve: 5g of ZSM-5 microporous molecular sieve (Si / Al molar ratio=27) was dissolved in 150ml of 0.2mol / L NaOH solution and stirred at 60°C for 5h. Then, it is filtered and dried to obtain ZSM-5 etched by alkali treatment.

[0031] (b) Heat 4.8g CTAB and dissolve it in 113ml distilled water, and let it stand for 8-10min after dissolving. Add 25g Na to the above solution 2 SiO 3 ·9H 2 O, stir and mix well, then add 1.584g of ZSM-5 that has been etched by alkali treatment, the molar composition of the system after stirring is: 1SiO 2 :0.15CTAB:65H 2 O, then use 2mol / L sulfuric acid to adjust pH=10.5, continue to stir at room temperature for 1h, then put it into the reaction kettle, and crystallize at 110°C for 24h. After the completion of crystallization, suction filtration, drying, and calcination at 550 ℃ for 6 hours to obtain the microporous-mesoporous ZSM-5 / MCM-41 composite molecular sieve sample ZM-1.

Embodiment 2

[0033] Heat 4.8g CTAB to dissolve it in 146ml distilled water, wait for 8min-10min after dissolving. Add 25g Na to the above solution 2 SiO 3 ·9H 2 O, after stirring and mixing well, add 0.768g of ZSM-5 which has been etched by alkali treatment in Example 1, and the molar composition of the system after stirring is 1SiO 2 :0.15CTAB:80H 2 O, then use 2mol / L sulfuric acid to adjust pH=10.5, continue to stir at room temperature for 2h, then put it into the reactor, and crystallize at 100℃ for 72h. After the completion of crystallization, suction filtration, drying, and calcination at 550°C for 6 hours to obtain the microporous-mesoporous ZSM-5 / MCM-41 composite molecular sieve sample ZM-2.

Embodiment 3

[0035] (a) Acid treatment of ZSM-5: 5g of ZSM-5 microporous molecular sieve (Si / Al molar ratio=27) was dissolved in 150ml of 0.1mol / L citric acid solution, and stirred at 80°C for 2h. Then filter and dry to obtain ZSM-5 etched by acid treatment.

[0036] (b) Heat 4.8g CTAB and dissolve it in 146mL distilled water, wait for 8min~10min after dissolution. Add 25g Na to the above solution 2 SiO 3 ·9H 2 O, stir and mix well, add 1.584g of ZSM-5 that has been acid treated and etched, and the molar composition of the system after stirring is 1SiO 2 :0.15CTAB:80H 2 O, then use 2mol / L sulfuric acid to adjust pH=10.5, continue to stir at room temperature for 3h, then put it into the reactor, and crystallize at 110℃ for 24h. After the completion of crystallization, suction filtration, drying, and calcination at 550°C for 6 hours to obtain the microporous-mesoporous ZSM-5 / MCM-41 composite molecular sieve sample ZM-3.

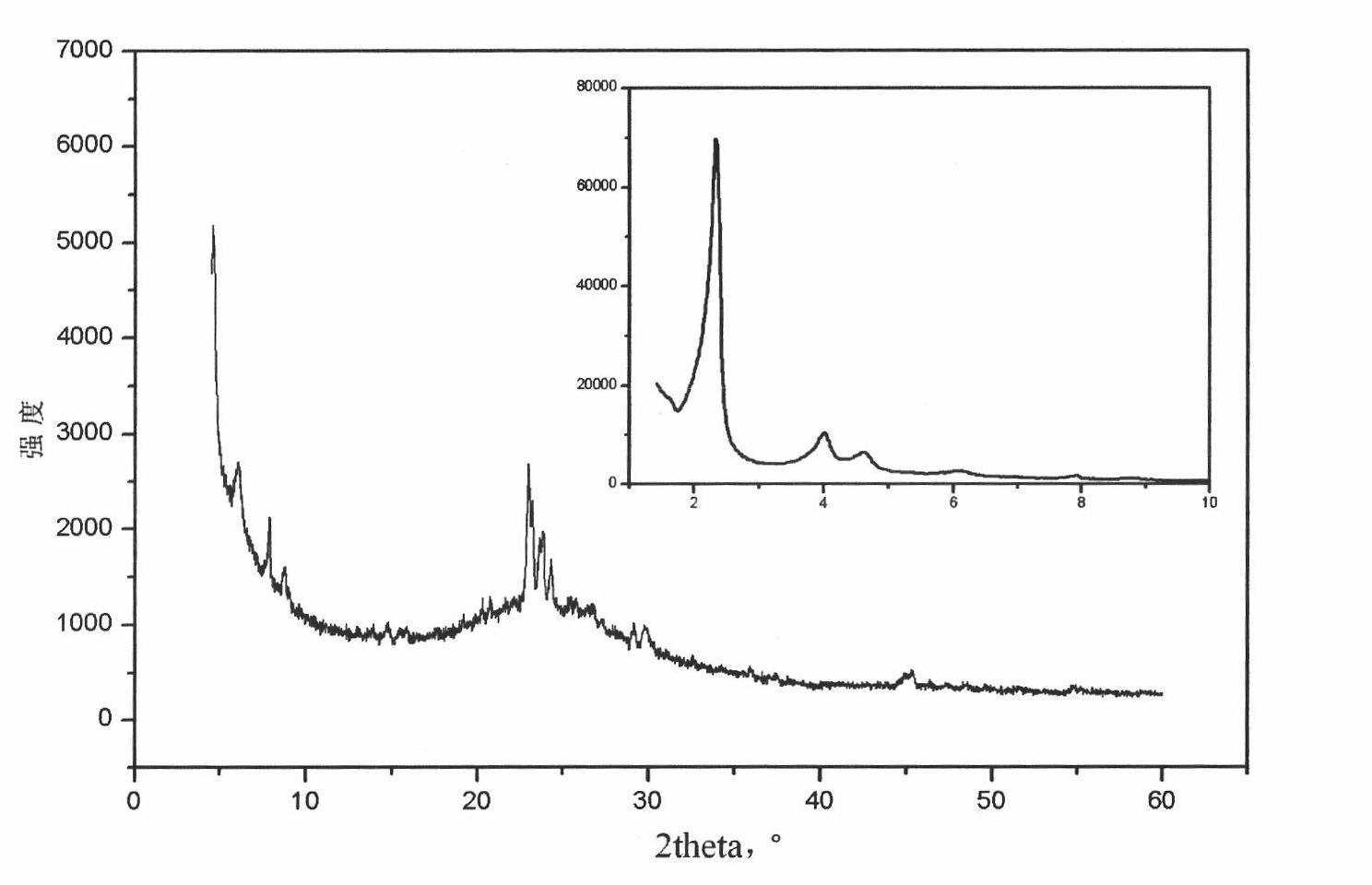

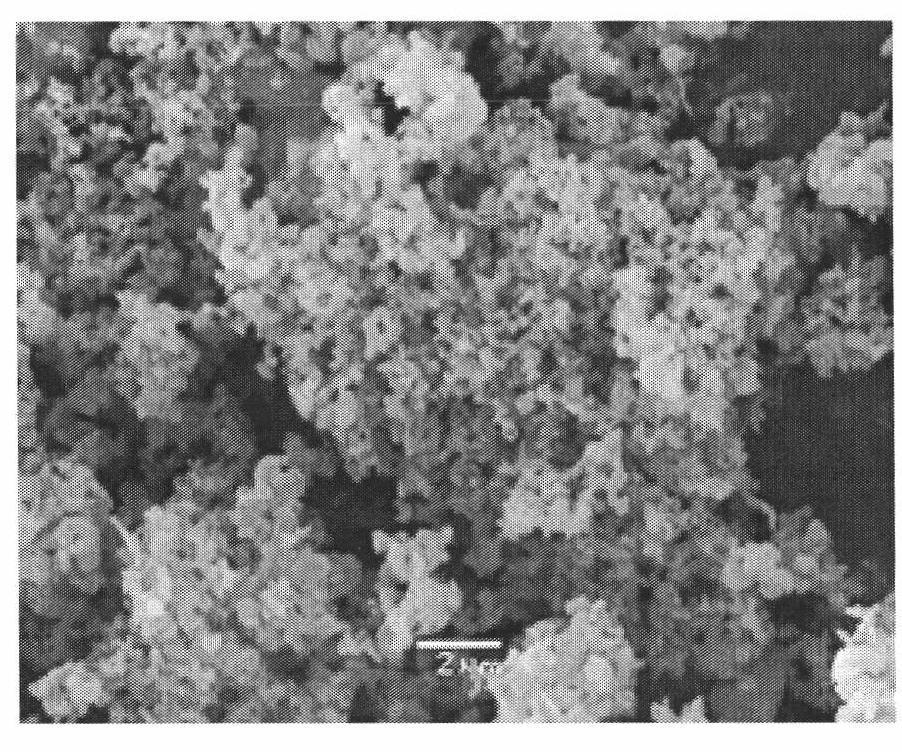

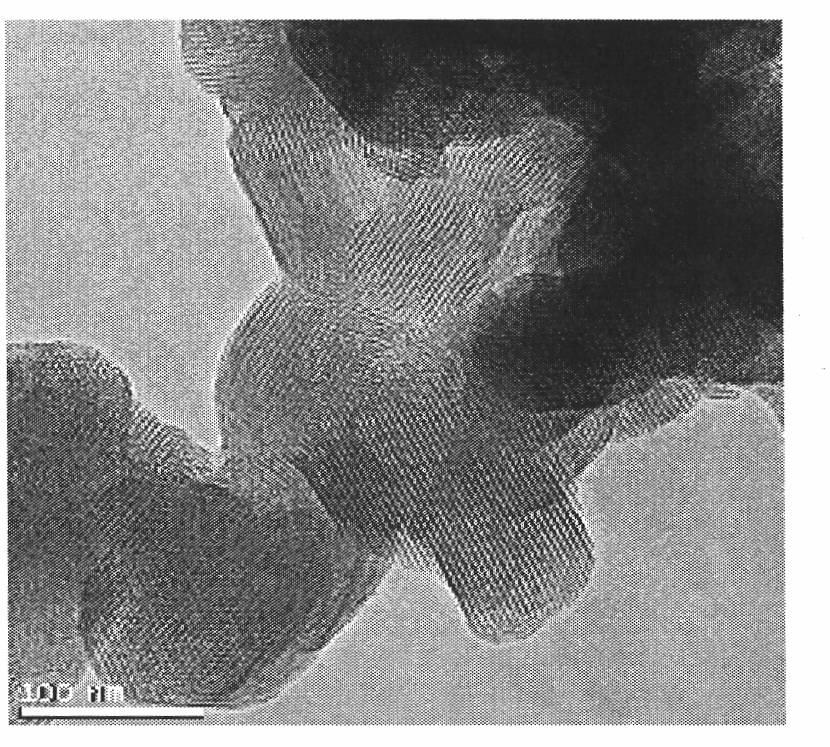

[0037] figure 1 It is the X-ray diffraction (XRD) spectrum of ZM-3, from w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com