Hydrotreatment method of heavy distillate oil

A technology for hydrotreating and heavy distillate oil, which is applied in hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., and can solve problems such as inability to ease operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

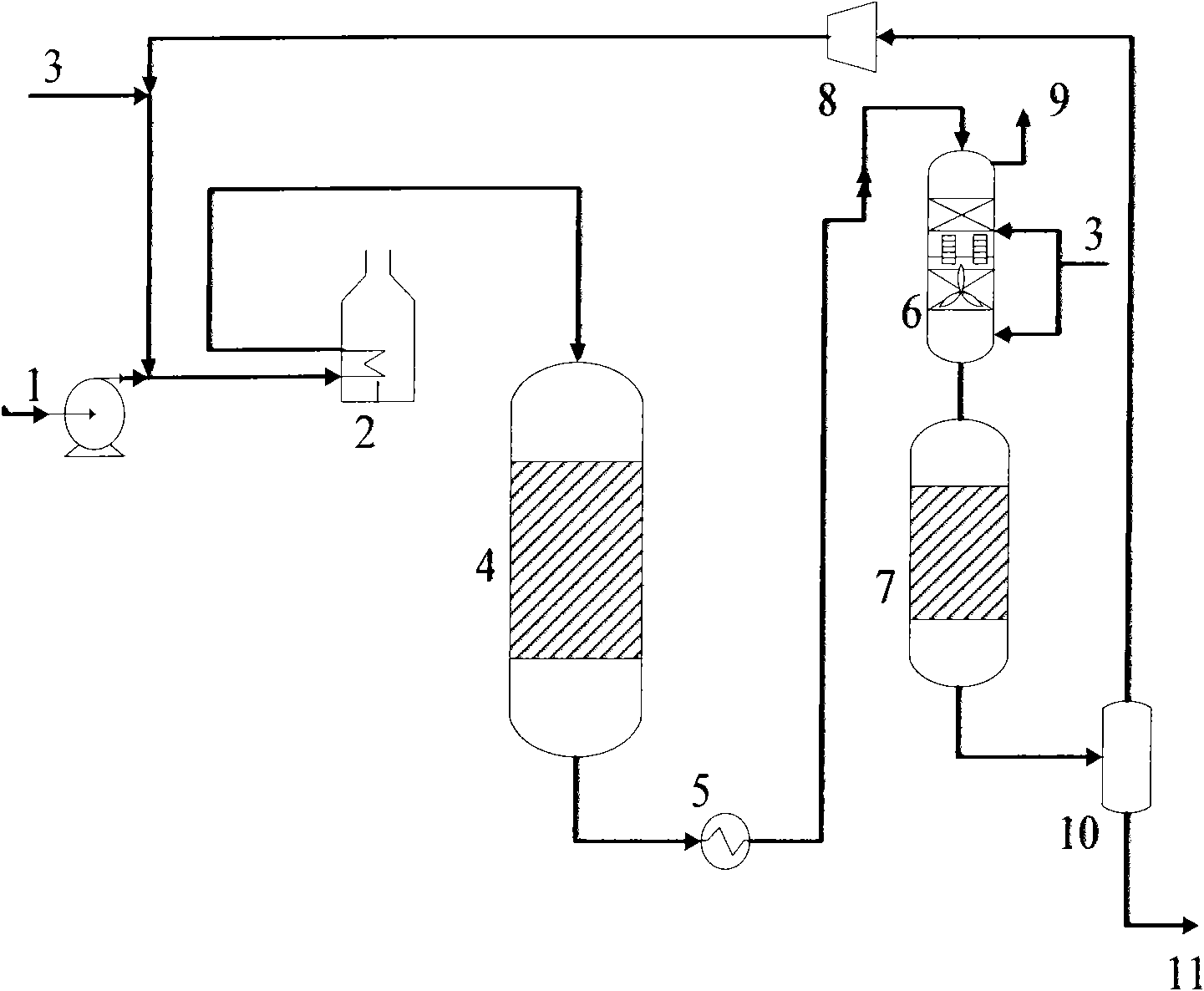

Method used

Image

Examples

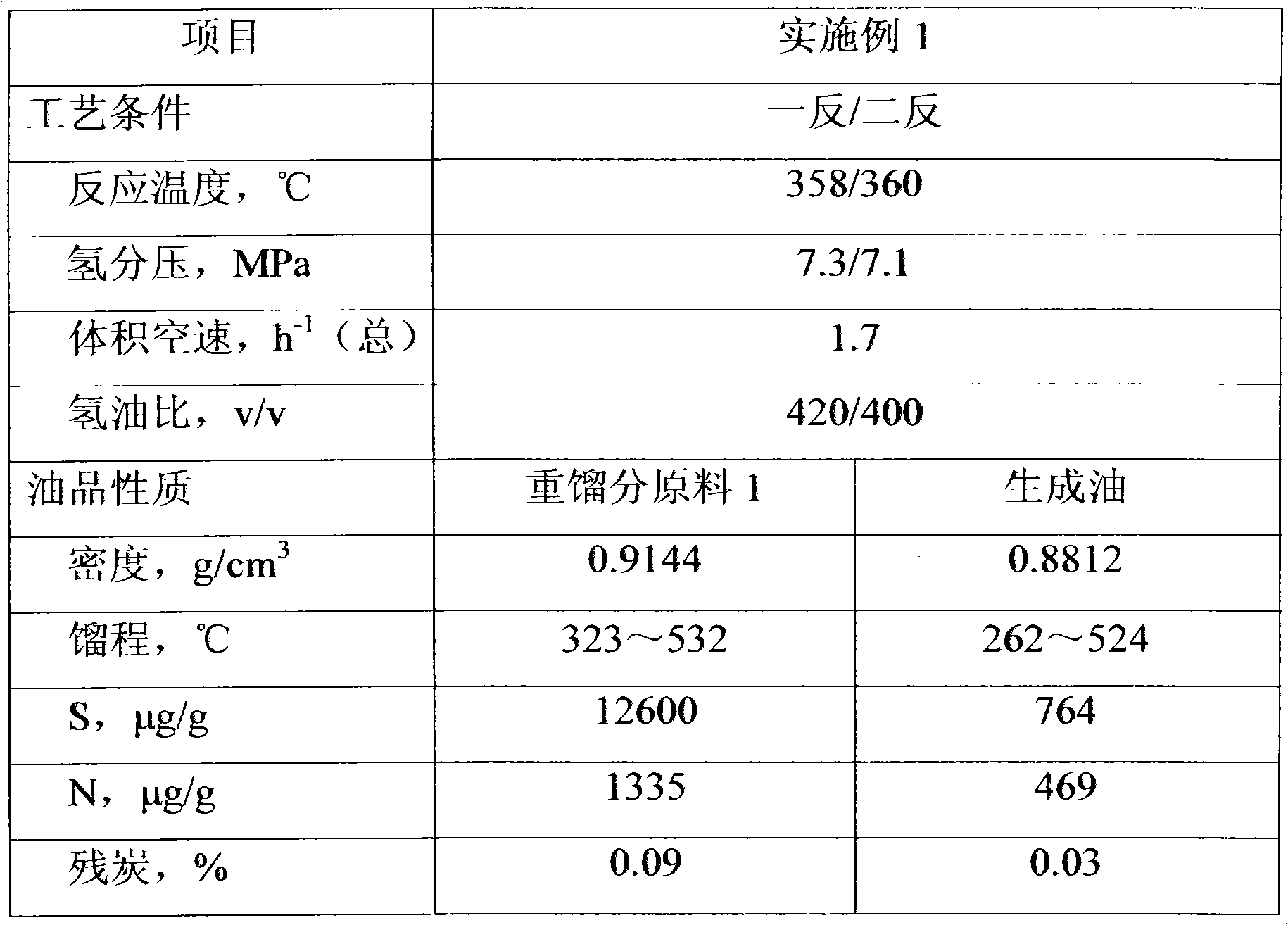

Embodiment 1

[0030] Heavy distillate oil raw material 1 goes through the heating furnace to reach the required temperature and fully mixes and dissolves hydrogen in the gas-liquid mixer, then enters the first hydrogenation reactor. The reaction conditions are: hydrogen partial pressure 7.3MPa, reaction temperature 358°C, hydrogen oil The volume ratio is 420:1. The effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer. The reaction conditions are: hydrogen partial pressure 7.1MPa, reaction temperature 360°C, hydrogen-oil volume ratio 400:1. Total volumetric space velocity 1.7h -1 . The raw material oil properties and product properties are listed in Table 2.

[0031] It can be seen from Table 2 that the impurity content in heavy distillate oil can be significantly reduced by using this technology.

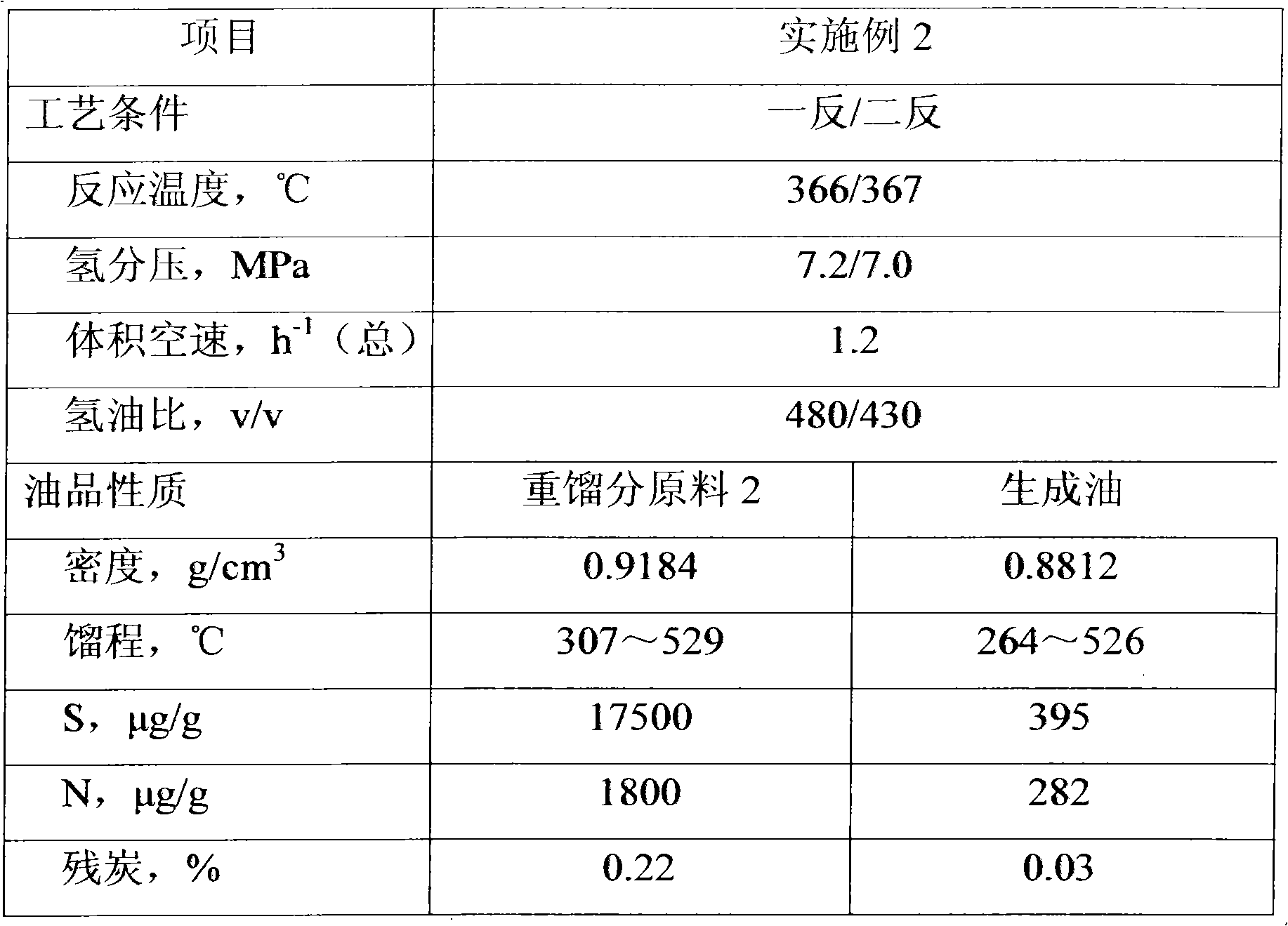

Embodiment 2

[0033] The heavy distillate oil raw material 2 goes through the heating furnace to reach the required temperature and fully mixes and dissolves the hydrogen in the gas-liquid mixer before entering the first hydrogenation reactor. The reaction conditions are: hydrogen partial pressure 7.2MPa, reaction temperature 366°C, hydrogen oil The volume ratio is 480:1. The effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer. The reaction conditions are: hydrogen partial pressure 7.0MPa, reaction temperature 367°C, hydrogen-oil volume ratio 430:1. Total volumetric space velocity 1.2h -1 . The raw material oil properties and product properties are listed in Table 3.

[0034] It can be seen from Table 3 that the impurity content in heavy distillate oil can be significantly reduced by using this technology.

Embodiment 3

[0036] The heavy distillate oil raw material 3 goes through the heating furnace to reach the required temperature and fully mixes and dissolves with hydrogen in the gas-liquid mixer, and then enters the first hydrogenation reactor. The reaction conditions are: hydrogen partial pressure 6.7MPa, reaction temperature 367℃, hydrogen oil The volume ratio is 500:1. The effluent enters the second hydrogenation reactor after passing through the gas stripping hydrogen mixer. The reaction conditions are: hydrogen partial pressure 6.5MPa, reaction temperature 367°C, hydrogen-oil volume ratio 520:1. Total volumetric space velocity 1.6h -1 . The raw material oil properties and product properties are listed in Table 4.

[0037] It can be seen from Table 4 that the impurity content in heavy distillate oil can be significantly reduced by using this technology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com