Electrical control system of steel plate edge milling machine

An electrical control system and control system technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the problems affecting the welding quality of steel pipes, low processing quality, low production efficiency, etc. The effect of good overall performance and high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

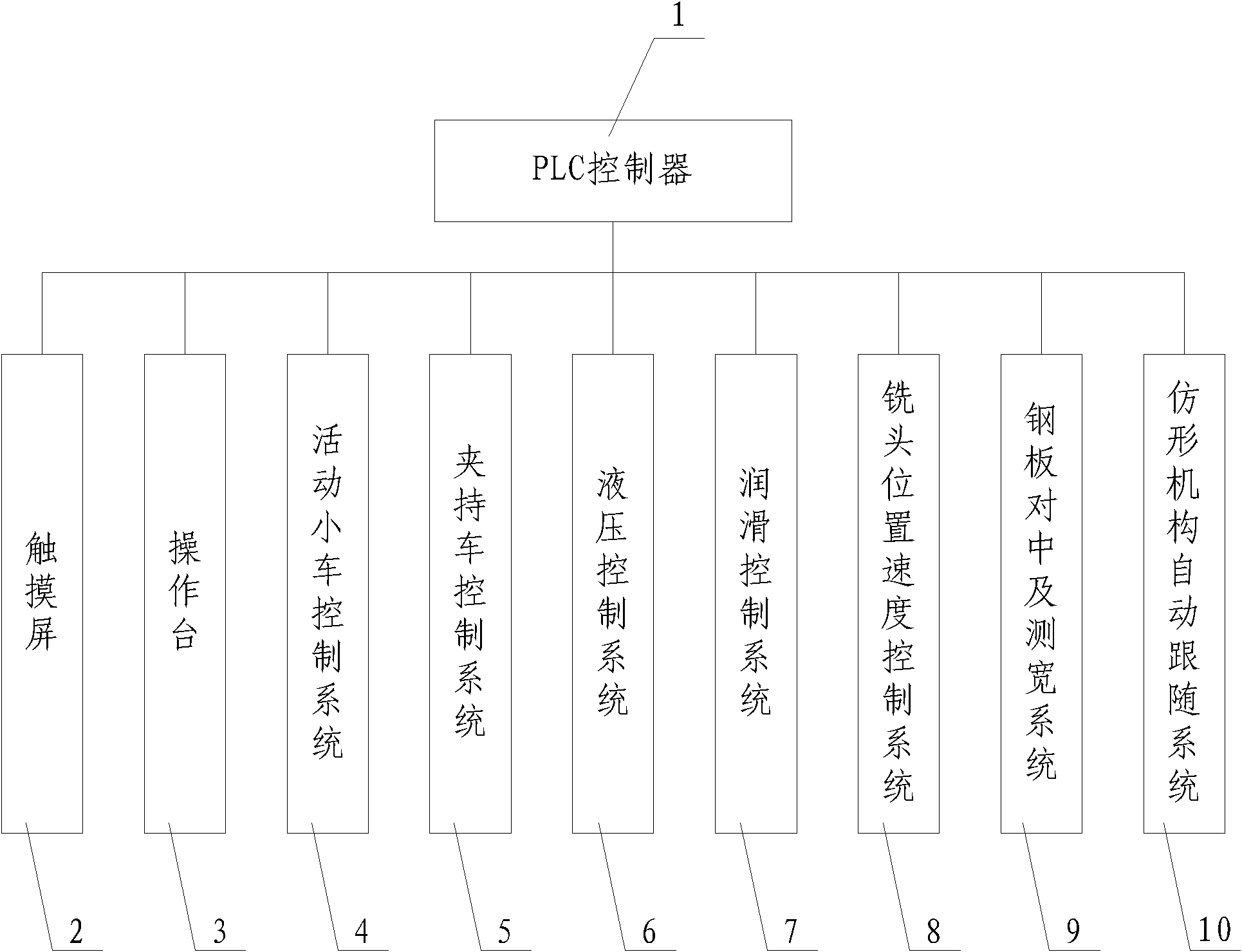

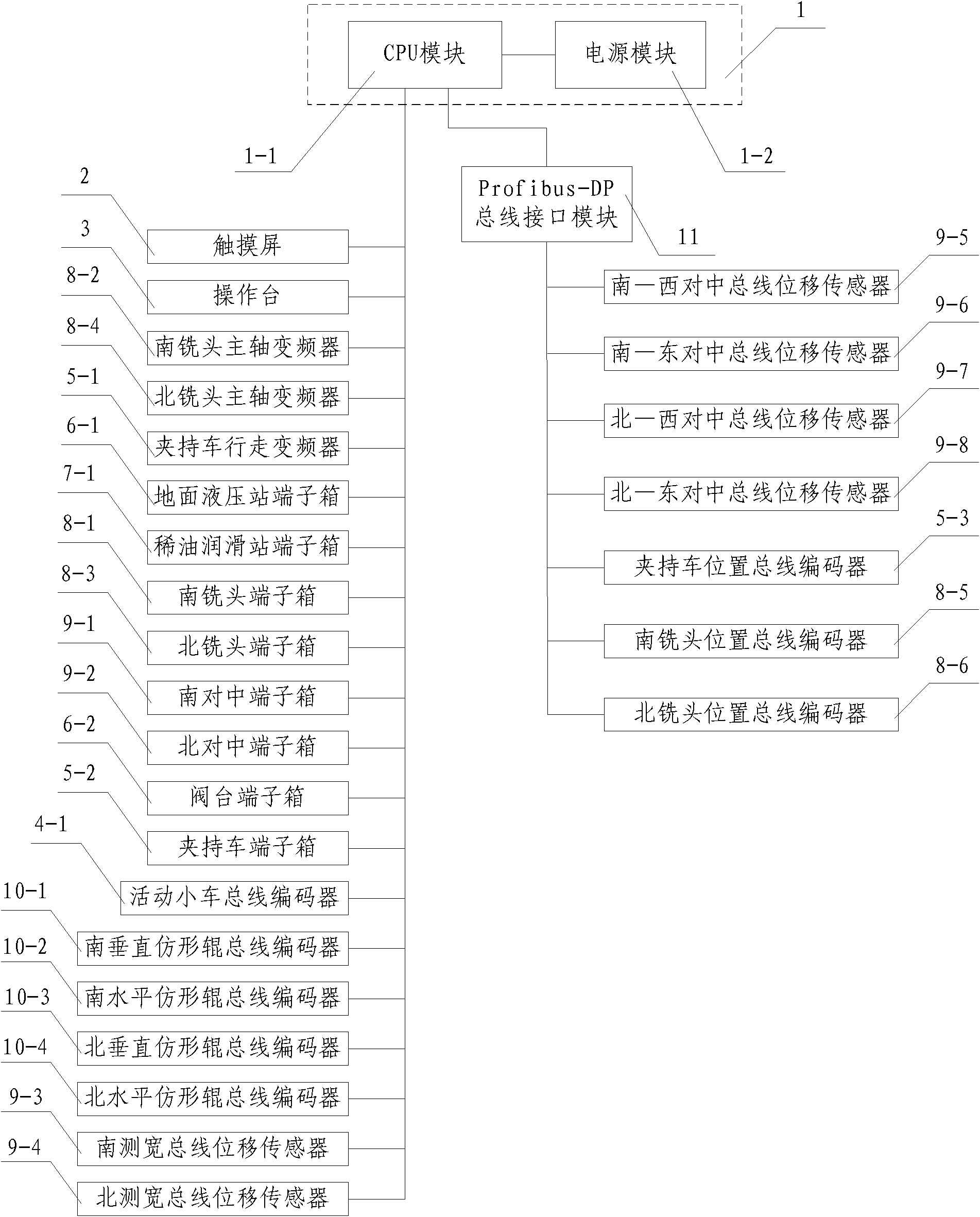

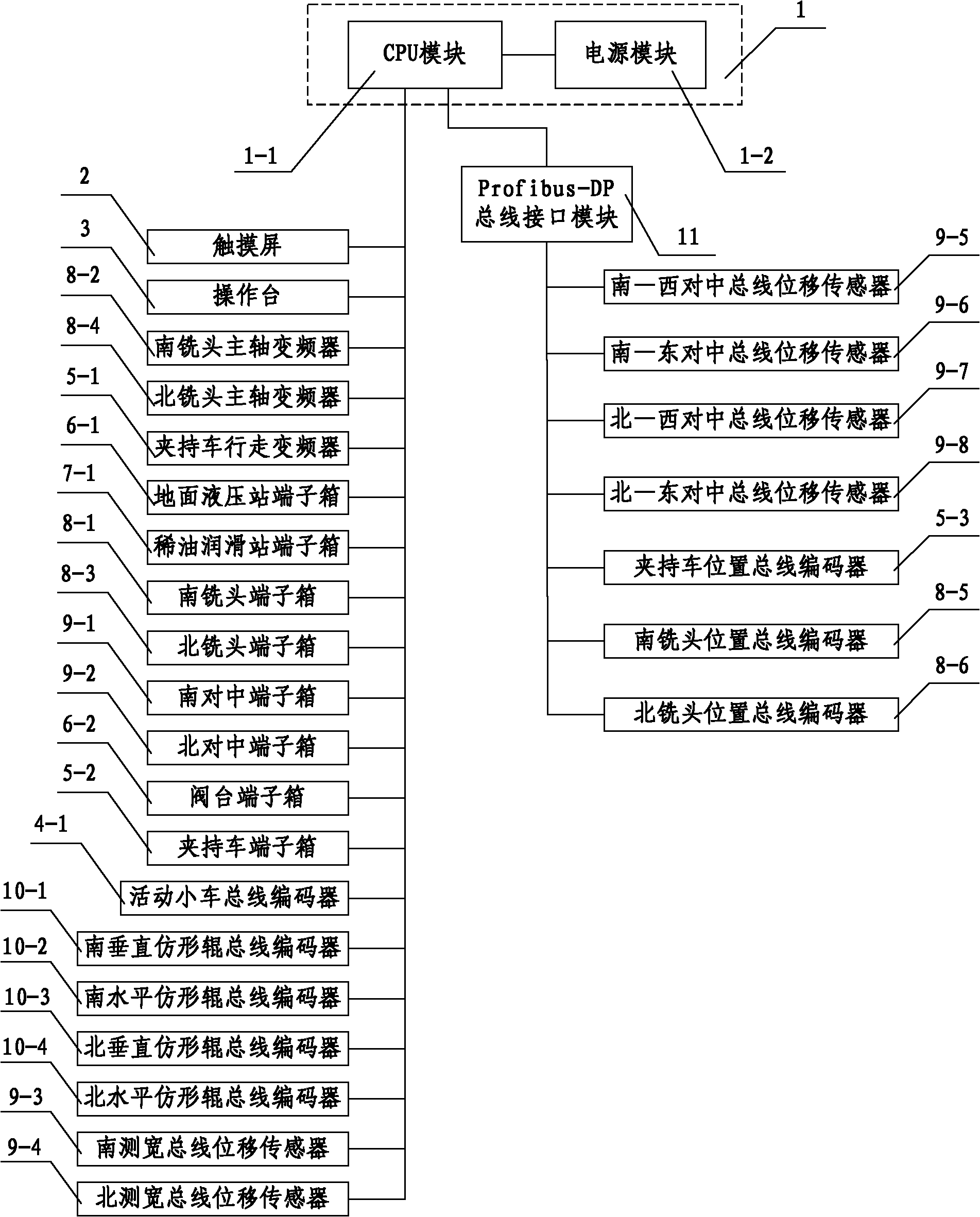

[0048] like figure 1 and figure 2As shown, the present invention includes a PLC controller 1 and a touch screen 2 connected to the PLC controller through the Profibus-DP bus, an operation console 3, a movable trolley control system 4, a clamping vehicle control system 5, a hydraulic control system 6, and a lubrication control system. System 7, milling head position and speed control system 8, steel plate centering and width measurement system 9 and copying mechanism automatic follow system 10, the Profibus-DP bus includes a Profibus-DP bus directly connected to the PLC controller 1. And the Profibus-DP bus 2 connected with the PLC controller through the Profibus-DP bus interface module 11, the movable trolley control system 4 is composed of the movable trolley bus encoder 4-1 connected on the Profibus-DP bus 1, so The clamping vehicle control system 5 consists of a clamping vehicle traveling frequency converter 5-1 connected to the first Profibus-DP bus, a clamping vehicle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com