Particle filtering device and regenerating method thereof

A particle filtration and particle technology, which is applied in the direction of noise reduction device, exhaust device, and electronic control of exhaust treatment device, can solve the problems of affecting the normal operation of pneumatic devices, high manufacturing cost, large gas consumption, etc., to improve the regeneration effect. , The effect of low modification cost and overall cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

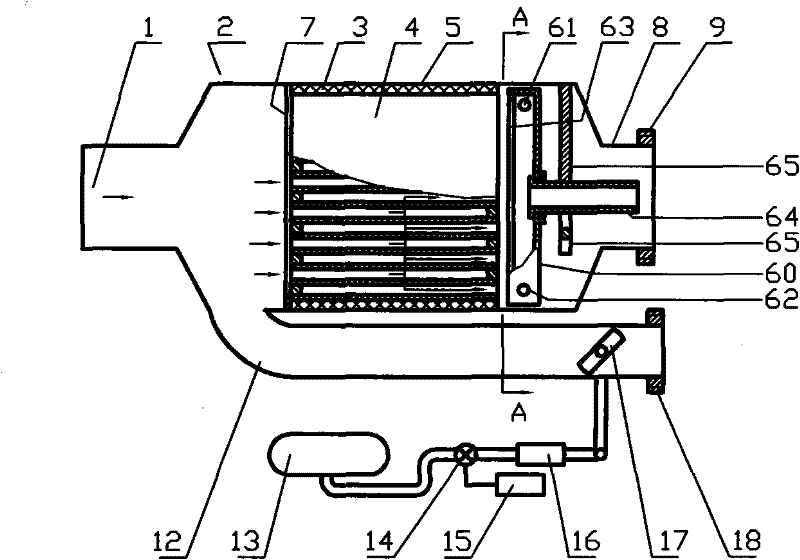

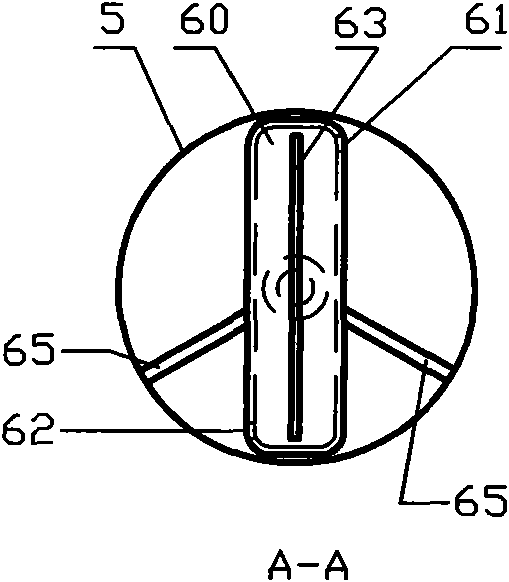

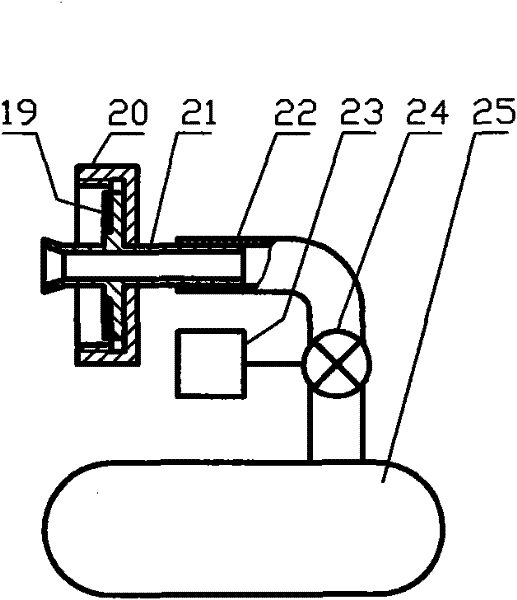

[0016] figure 1 , figure 2 It is a schematic structural diagram of an embodiment of the particle filter device 2 of the present invention, figure 1 The arrow in front of the ceramic filter 4 in the middle is the exhaust gas flow direction containing particles, and the arrow in the ceramic filter 4 is the exhaust gas flow direction without particles. Now refer to the accompanying drawings.

[0017] The device comprises a wall-flow ceramic filter 4 with a diameter of 190 mm and a length of 200 mm for particle filtration, a housing 5 made of stainless steel, and an elastic seal is pressed between the outer surface of the ceramic filter 4 and the inner wall of the housing 5 Material 3, the front end of the housing 5 is provided with an intake pipe 1 connected to the engine exhaust port, the rear end of the housing 5 is provided with an exhaust pipe 8, and the inner wall of the housing 5 is provided with a ceramic filter 4 that blocks the movement of the ceramic filter 4 to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com