Multi-layer conductive transparent film and method for increasing light emitting efficiency of light emitting device

A technology of conductive transparent film and light extraction efficiency, applied in semiconductor devices, circuits, electrical components, etc., can solve problems such as affecting applications, poor P-type GaN ohmic contact, etc., to increase device size, reduce optical power loss, and improve light output. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

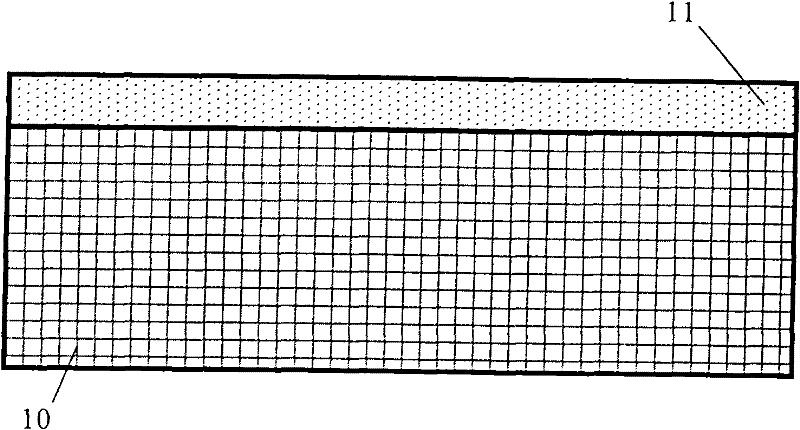

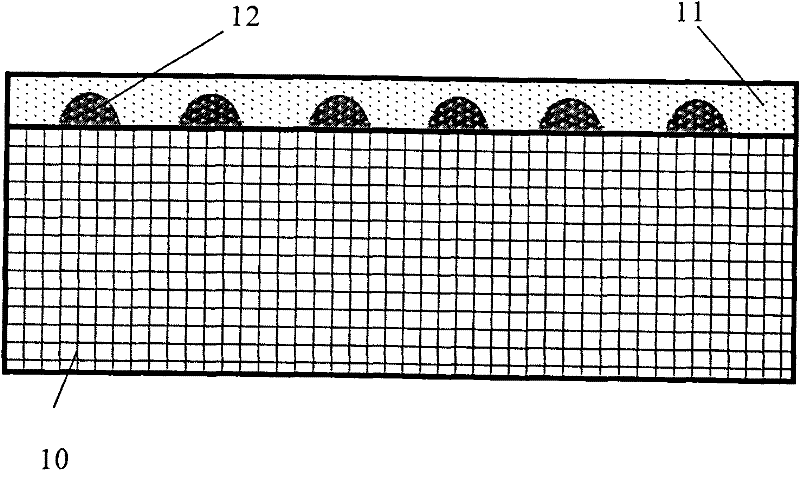

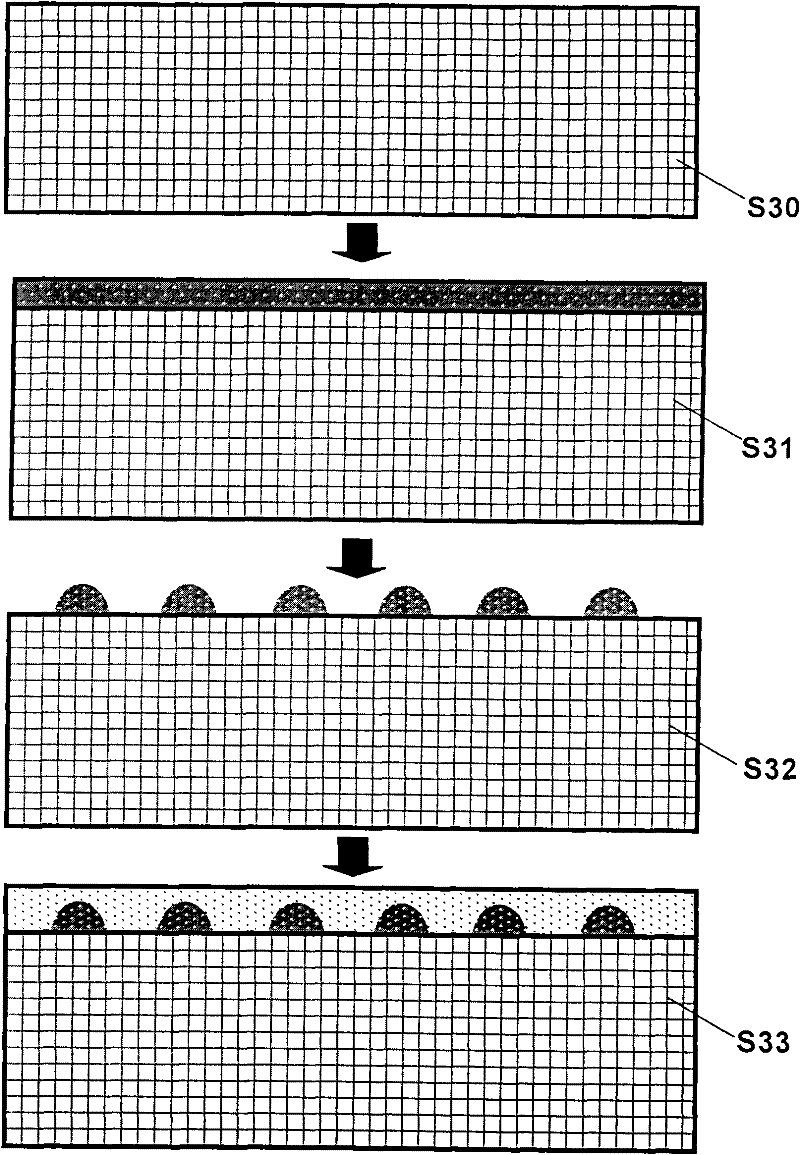

[0030] refer to figure 2 As shown, the multilayer conductive transparent film used to improve the light-emitting efficiency of the light-emitting device of the present invention also includes a high-refractive-index transparent electrode layer 12 grown on the P-type GaN surface epitaxial wafer 10, and then on the high-refractive-index transparent electrode layer 12 The outer surface of the ITO transparent electrode layer 11 is covered.

[0031] The main inventive point of the present invention is that a transparent electrode layer 12 with a high refractive index n>2.0 is sandwiched and grown between the P-type GaN surface epitaxial wafer 10 and the ITO transparent electrode layer 11 of the traditional GaN-based optoelectronic device. This transparent electrode layer 12 can select P-type ZnO electrode layer thin film for use (as: ZrO2-Y2O3, In2O3-Sb2O3, AlSb, GaSb, InGaSb, InSb, AlAs, InSb, AgBr, TlBr, AgCl, TlCl, CoSi2, TiSi etc.), The thickness of the P-type ZnO electrode l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com