Far-infrared antibacterial fabric

An antibacterial fabric, far-infrared technology, applied in the field of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

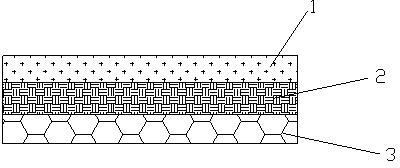

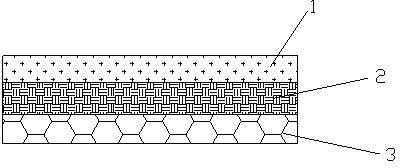

Image

Examples

Embodiment 1

[0018] The specific preparation process of the fabric is as follows:

[0019] a) Preparation of surface yarns. The surface materials are made of 35% bamboo charcoal fiber and 65% nylon 66 fiber. Low twist yarns are made through cleaning, carding, drawing, roving, spun yarn, winding and twisting processes. .

[0020] b) Pretreatment of surface yarns. The pretreatment process includes yarn dyeing, color fixation, reduction cleaning, and drying. The dyeing agent is sulfurized deep blue 3R, and the color fixing agent is chlorine-resistant color fixing agent. HX-78 / 18; the temperature of the color fixing treatment is controlled at 20°C, the pH of the dye bath is adjusted to 4-5 with acetic acid, the dye bath is circulated and the temperature is raised to 50°C, and the treatment is 20 minutes; the drying temperature is controlled Below 90°C.

[0021] c) The preparation of the middle layer fabric. The synthetic fiber materials used in the middle layer are polyester, nylon 6 and spa...

Embodiment 2

[0032] The specific preparation process of the fabric is as follows:

[0033] a) Preparation of surface yarns. The surface materials are made of 30% bamboo charcoal fiber and 70% nylon 66 fiber. Low twist yarns are made through cleaning, carding, drawing, roving, spun yarn, winding and twisting processes. .

[0034] b) Pretreatment of surface yarns. The pretreatment process includes yarn dyeing, color fixing, reduction cleaning, and drying. The dyeing agent is sulfur red 3R, and the color fixing agent is chlorine-resistant color fixing agent HX. -78 / 18; the temperature of the color fixing treatment is controlled at 25°C, the pH of the dye bath is adjusted to 4-5 with acetic acid, the dye bath is circulated and the temperature is raised to 50°C, and the treatment is performed for 20 minutes; the drying temperature is controlled at Below 90°C.

[0035] c) The preparation of the middle layer fabric. The synthetic fiber materials used in the middle layer are polyester, nylon 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com