Relevance method of continuous annealing machine set detection signals and band steel positions

A unit detection and signal technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as inability to provide positioning information, difficulty in analyzing the impact of quality, and inability to achieve complete correlation of steel coil information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The process information collected in the annealing process area of the continuous annealing production line of the present invention and the production entrance volume number, strip steel position (length from the coil head) correlation integration method includes the following steps:

[0027] Step 1. Set the benchmark

[0028] Set several datum points, and calculate the result of volume association through the datum point weld seam information in the database.

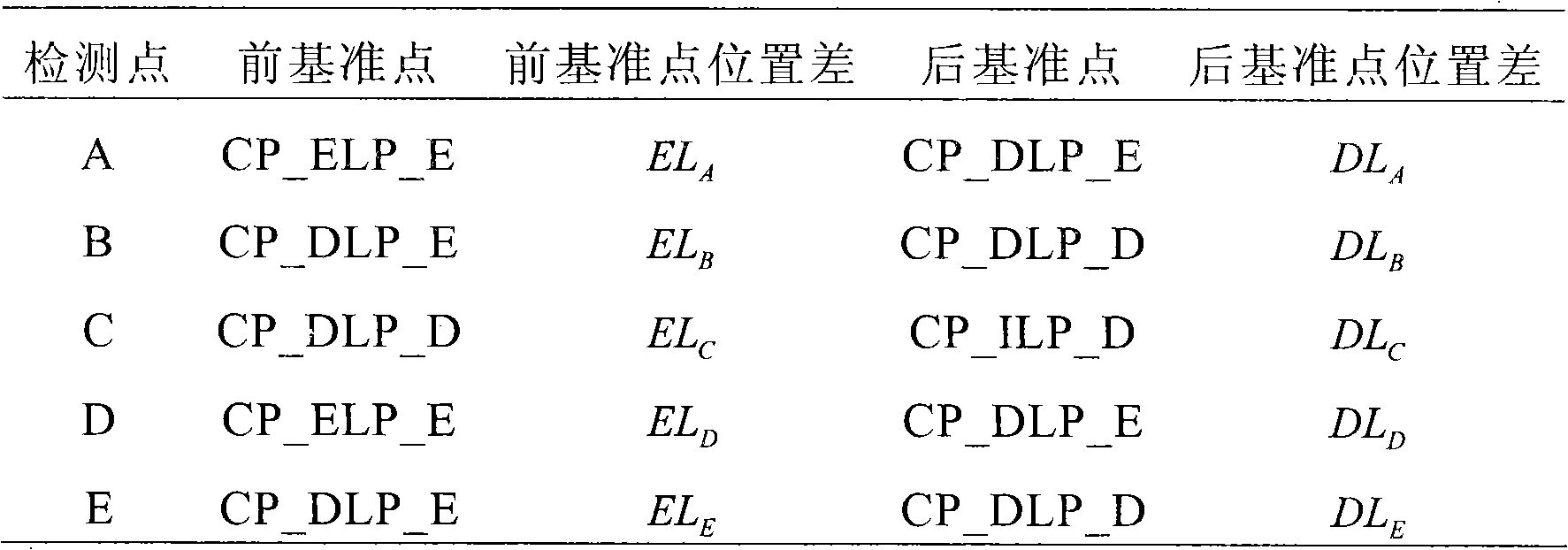

[0029] The reference points are set as follows: before the entrance looper, before the exit looper, after the exit looper, and after the detection looper, the codes are respectively "CP_ELP_E", "CP_DLP_E", "CP_DLP_D", "CP_ILP_D"

[0030] Step 2. Calculate the length of the entry volume

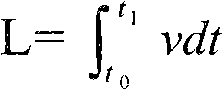

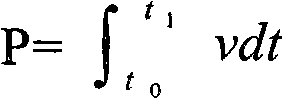

[0031] The length of the entry coil of the strip is calculated by the weld time of the coil number at the reference point "before the exit loop" and the speed of the central section. The calculation formula is:

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com