Method for preparing silver tea from summer tea and autumn tea

A technology for silver tea and autumn tea, which is applied in the field of making silver tea from summer and autumn tea, achieves the effects of changing taste, low price and lowering cholesterol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

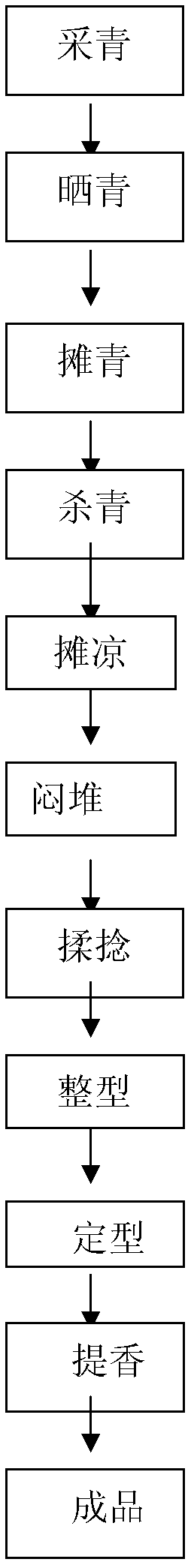

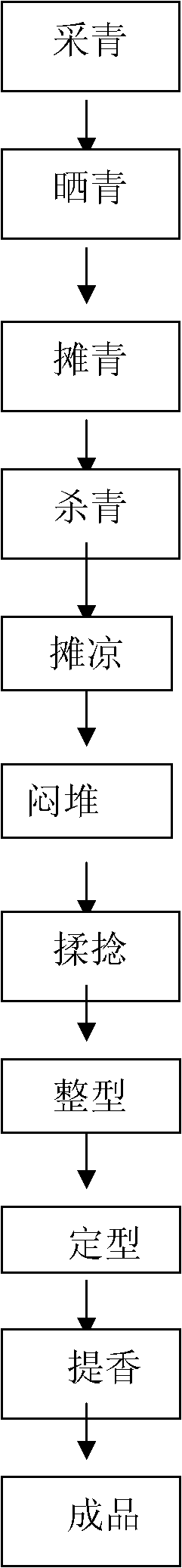

Method used

Image

Examples

Embodiment 1

[0028] 1. Green picking: pick 500kg of raw materials of summer tea, one bud and one leaf, of the Fuyun No. 6 tea variety.

[0029] 2. Green sun drying: After the fresh leaves enter the factory, spread the fresh leaves on the bamboo sieve, each bamboo sieve spreads 0.8~1.2kg of fresh leaves, the thickness is 3~5cm, and put them in the sun at a temperature of 25~28℃ Green for 20 minutes, if the temperature exceeds 30°C during the drying process, the shade net needs to be pulled.

[0030] 3. Spread green: put the dried tea into the green stand and spread it in the green stand. The thickness of the spread depends on the weather. The buds and leaves are 1-2kg per square meter; the thickness of the spread is about 3 cm. The time of spreading in the environment is 8-12 hours, and the weight loss rate after spreading is required to be more than 15%; the moisture content of tea leaves is 65-75%.

[0031] 4. Finishing: the tea leaves after spreading green are finished at a temperature ...

Embodiment 2

[0039] 1. Green picking: pick 500kg of autumn tea with one bud and one fresh leaf of the Fuyun No. 6 tea variety.

[0040] 2. Green drying: After the fresh leaves enter the factory, spread the fresh leaves on the bamboo sieve, each bamboo sieve spreads 1.0kg of fresh leaves, the thickness is 4cm, and dry the green leaves under artificial light for 30 minutes; the moisture content of the tea leaves is 65~ 70%.

[0041] 3. Green spreading: Put the sun-dried tea leaves in the green stand, the buds and leaves are 1 kg per square meter; the thickness of the spread is about 2 cm, and the green spread is placed in an environment of 18-22 °C for 10-12 hours. After spreading, the weight loss rate is more than 15%.

[0042] 4. Finishing: the tea leaves after spreading green are finished at a temperature of 250-280° C. for 2-3 minutes, and the moisture content of the finished leaves is 50%.

[0043] 5. Cooling: Spread the green leaves and spread them for 35 minutes under the condition of...

Embodiment 3

[0050] 1. Green picking: pick 500kg of raw materials of summer tea, one bud and one leaf, of the Fuyun No. 6 tea variety.

[0051] 2. Green drying: After the fresh leaves enter the factory, spread the fresh leaves on the bamboo sieve, each bamboo sieve spreads 0.9~1.1kg of fresh leaves, the thickness is 3~4cm, and puts them in the sun at a temperature of 25~28℃. Green for 30 minutes. If the temperature exceeds 30°C during drying, you need to pull the shade net.

[0052] 3. Spread green: Put the dried tea into the green stand and spread it in the green stand. The thickness of the spread depends on the weather. The bud leaves are 2kg per square meter; The spreading time is 9-12 hours, and the weight loss rate after spreading is required to be more than 15%; the moisture content of the tea leaves is 70-75%.

[0053] 4. Finishing: the tea leaves after spreading green are finished at a temperature of 260-270°C for 2-3 minutes, and the moisture content of the finished leaves is 60%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com