Method for extracting oyster peptide

An extraction method, oyster peptide technology, applied in the field of enzymatic hydrolysis and extraction of oyster peptides, can solve the problems of low enzymatic hydrolysis rate and achieve the effect of high content of small peptides, perfect composition and complete absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

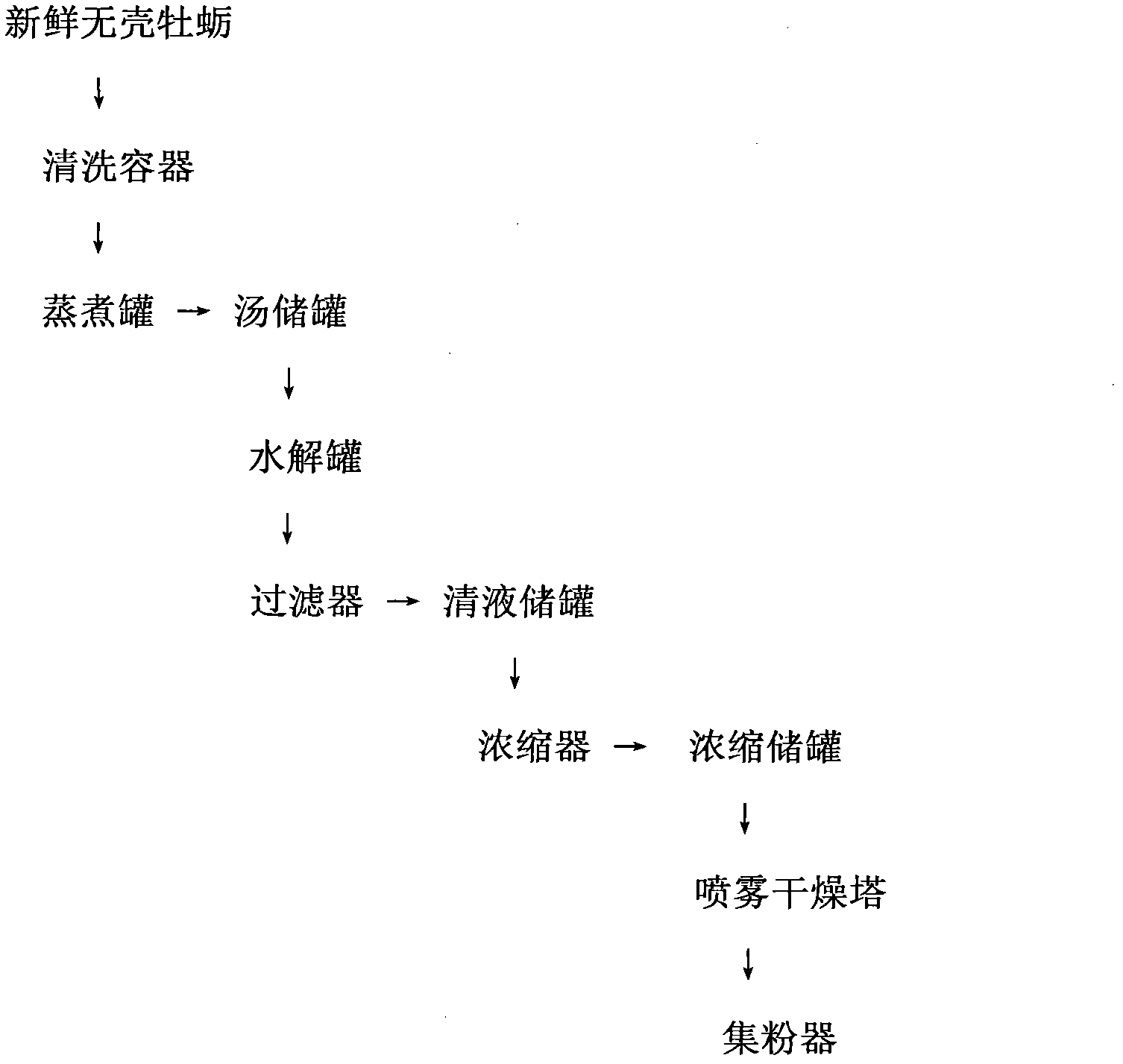

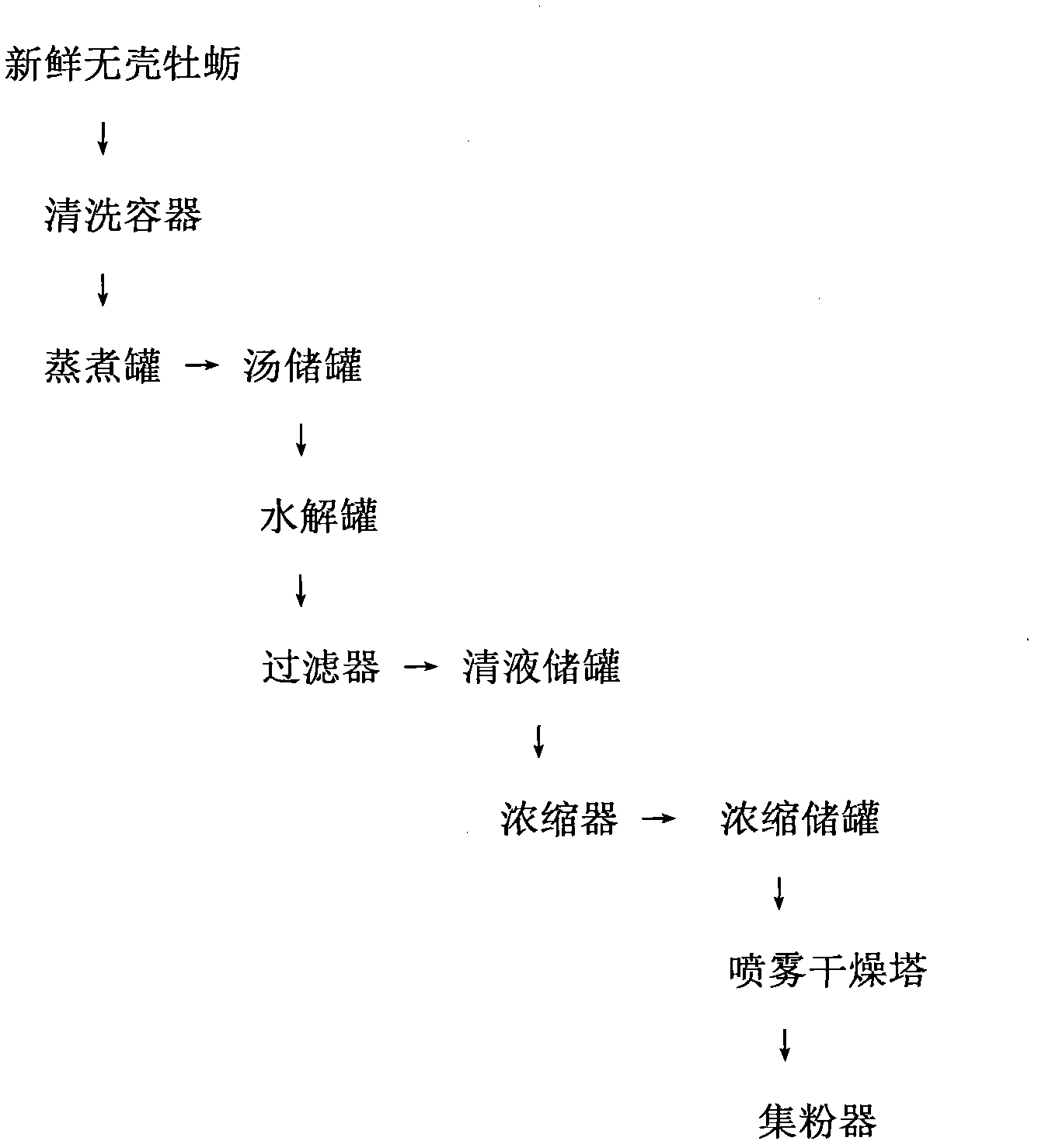

[0020] Depend on figure 1 Visible, a kind of extraction method of oyster peptide, its technological process is:

[0021] Cleaning → high pressure cooking → enzymatic hydrolysis → deodorization → filtration → concentration → drying → finished product packaging,

[0022] (1) Cleaning: In the cleaning container, rinse the surface of the oyster meat with cold water until the dirt is washed away;

[0023] (2) High-pressure cooking: The oyster meat is cooked as a whole. In the cooking tank, the temperature is 120°C-130°C, the pressure is 0.13-0.15MPa, and the constant temperature and pressure are steamed for 2 hours. The oyster extract is discharged into the soup storage tank, and the oyster meat dregs are discharged. ;

[0024] (3) Enzymolysis: the oyster extract is discharged from the soup storage tank into the hydrolysis tank, heated and sterilized, then cooled to 52°C-54°C, added NaOH to adjust the pH to 7.0, and then added 0.5% oyster special enzyme by weight of dry matter ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com