Device for continuously producing exenatide microspheres and method for controlling release rate of microspheres

A technology of exenatide and microspheres, which is applied in the field of devices for controlling the uniformity of exenatide microspheres, can solve the problems of incomplete release, burst release of microspheres, and reduced drug efficacy, and achieve complete release and reduced drug efficacy. The effect of burst release and improvement of encapsulation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The polymer used in this example is Poly(lactic-co-glycolic acid) (PLGA) 2A DL (lactide:glycolide=50:50) with an intrinsic viscosity (ie IV) of 0.39.

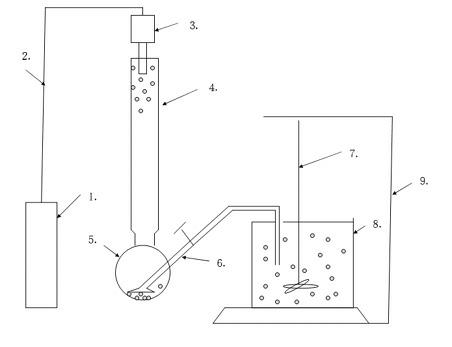

[0065] Improved S / O / W double emulsification method

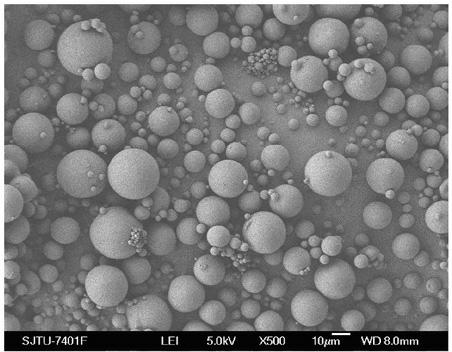

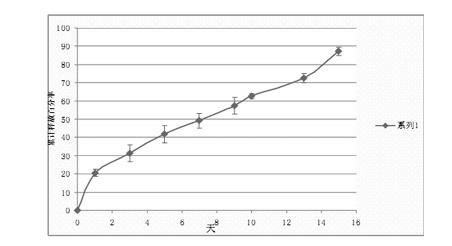

[0066] Add 5 mg of exenatide freeze-dried powder directly to 100 μl DMSO solution to dissolve, then transfer to 1 ml of dichloromethane (DCM) dissolved in 150 mg PLGA (50:50) 2A, and vortex at high speed with a vortexer to disperse evenly . Then add 10 mg of magnesium hydroxide powder into DCM, put it into a magneton and vortex at high speed to obtain a suspension in which exenatide and magnesium hydroxide fine particles are uniformly dispersed. Then add the suspension to figure 1 In the device, carry out emulsification. The particle size of the microspheres is controlled by adjusting the air pressure size and the pore size of the third part. On this basis, the dosage scale-up production was carried out according to this prescription until 200 mg exenatide wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com