Dry-type efficient and energy saving system for cleaning flue gas of multi-pollutants

A flue gas purification system, high-efficiency and energy-saving technology, applied in the field of flue gas purification, can solve the problems of flue gas purification process layout optimization without energy saving considerations, no waste heat recovery and utilization of flue gas, high investment and operating costs, etc., to reduce secondary pollution , Small footprint, small investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

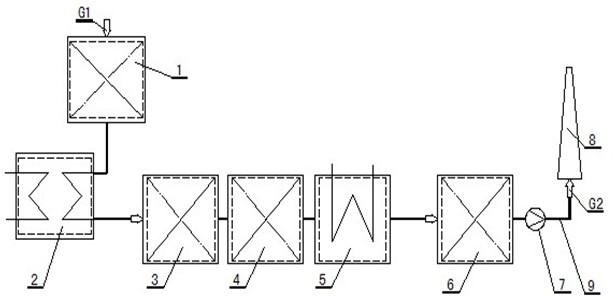

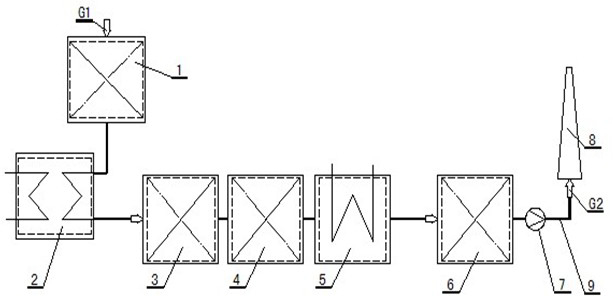

[0017] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, the dry-type high-efficiency energy-saving multi-pollutant flue gas purification system of the present invention includes a pre-denitration device 1, an air preheater 2, a pre-dust collector 3, and activated coke smoke Gas purification device 4, waste heat recovery device 5, dust collector 6 and smoke exhaust device 8, an induced draft fan 7 is arranged between the dust collector 6 and the smoke exhaust device 8; the original flue gas G1 passes through the removal part of the pre-denitration device 1 in sequence NOx, the air preheater 2 lowers the temperature of the flue gas to heat the combustion air, the pre-dust collector 3 removes most of the dust in the flue gas, and the activated coke flue gas purification device 4 removes various...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com