Preparation method for molecular imprinting film

A technology of molecularly imprinted membrane and preparation steps, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

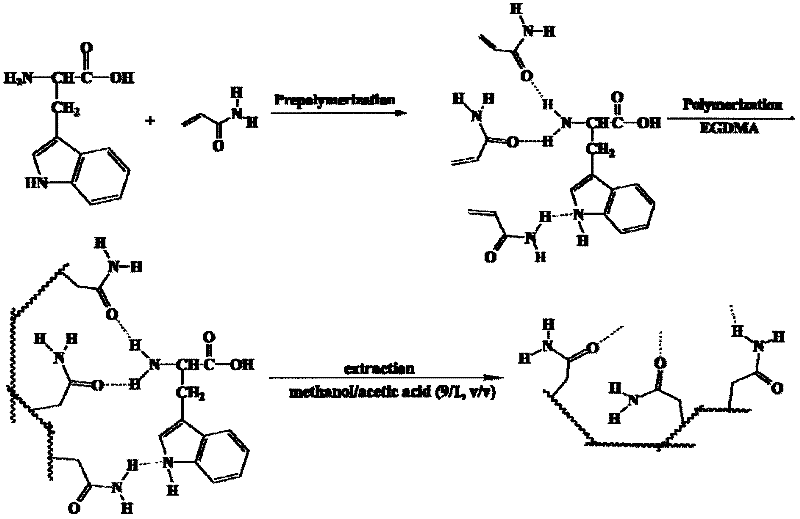

[0021] Example 1 Preparation of L-tryptophan molecularly imprinted membrane

[0022] Take the following technical measures in turn:

[0023] A. Before use, the nylon membrane is soaked in an aqueous solution of N,N,N',N'-tetramethylethylenediamine with a volume ratio of 10:1 for 40 minutes, and then taken out and placed in a vacuum oven at 35°C for 2 hours to dry.

[0024] B. Dissolve 0.1mmol of L-tryptophan in 20mL of acetone. After the template molecule is completely dissolved, add 0.4mmol of polymerized monomer acrylamide, and place it at 4°C for 6 hours, so that the template molecule can fully interact with the functional monomer. Then add 2mmol of cross-linking agent ethylene glycol dimethacrylate, ultrasonic degassing for 5min, and then high-purity nitrogen for 5min, after adding 15mg of initiator azobisisobutyronitrile, place the nylon membrane in the above reaction mixture solution , take it out after soaking for 1min, put it between two pieces of glass, squeeze it ha...

Embodiment 2

[0025] Embodiment 2 The preparation of sulfamethoxazole molecularly imprinted membrane

[0026] Take the following technical measures in turn:

[0027] A. The nylon membrane is soaked in an aqueous solution of N,N,N',N'-tetramethylethylenediamine with a volume ratio of 5:1 for 60 minutes before use, and then taken out and placed in a vacuum oven at 30°C for 6 hours to dry.

[0028] B. Dissolve 0.4mmol of template molecule sulfamethoxazole in 20mL of acetone. After the template is completely dissolved, add 1.6mmol of functional monomer acrylamide and place it at 4°C for 12 hours to allow the template molecule to fully interact with the functional monomer. Then 8 mmol of crosslinker ethylene glycol dimethacrylate was added. Ultrasonic degassing for 5 minutes, and then argon for 10 minutes, immediately put the nylon membrane in the above reaction mixture solution, soak for 1 minute and take it out. Place it between two pieces of clean and dry glass, squeeze it hard to remove ai...

Embodiment 3

[0029] Example 3 Preparation of Adrenaline Molecularly Imprinted Membrane

[0030] Take the following technical measures in turn:

[0031] A. The nylon membrane is soaked in an aqueous solution of N,N,N',N'-tetramethylethylenediamine with a volume ratio of 8:1 for 30 minutes before use, and then taken out and placed in a vacuum oven at 40°C for 6 hours to dry.

[0032] B. Dissolve 0.4mmol of the template molecule adrenaline in 20mL of glacial acetic acid. After the template is completely dissolved, add 1.6mmol of the functional monomer acrylamide and place it at 4°C for 8 hours to allow the template to fully interact with the functional monomer. Then 8 mmol of crosslinker ethylene glycol dimethacrylate was added. Ultrasonic degassing for 5 minutes, and then high-purity nitrogen for 5 minutes, immediately put the nylon membrane in the above reaction mixture solution, soak for 1 minute and take it out. Place it between two pieces of glass, squeeze it hard to remove air bubbles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com