Roll ball high-speed milling electric main shaft

A high-speed milling and electro-spindle technology, which can be applied to milling devices, milling machine equipment, clamping and other directions that can be installed on machine tools. Small, reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

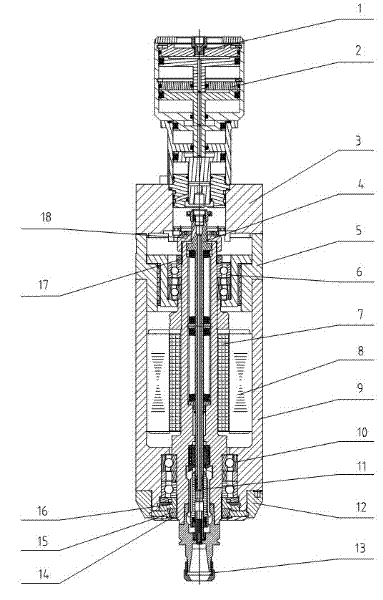

[0028] according to figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a tool change cylinder assembly 2 with a pipe joint 1, an aluminum water jacket assembly 3 with a power cord, an air source hole and a cooling water source interface, an upper bearing lock nut 17, and an air cylinder assembly 2 inside. The body assembly 9 of the road channel and the cooling water channel, wherein the head of the tool change cylinder assembly 2 is fixed in the rear inner cavity of the aluminum water jacket assembly 3, and the front end of the body assembly 9 is fixed with the lower cover 12 and the dust cover 14 of the body. There is a shaft core assembly 7 passing through the through holes of the upper bearing assembly 6, the stator 8 and the lower bearing assembly 10, and the axial through hole of the shaft core assembly 7 is provided with a pull rod assembly 4, a pull claw assembly 11 and a knife assembly from top to bottom. The handle assembly 13 is...

Embodiment 2

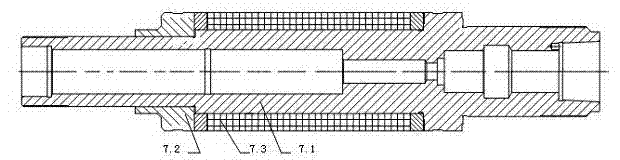

[0030] Same as Embodiment 1, except that the shaft section 7.1 below the shaft shoulder sleeve 7.2 on the shaft core body of the shaft core assembly 7 is fixed with a copper squirrel cage rotor 7.3.

Embodiment 3

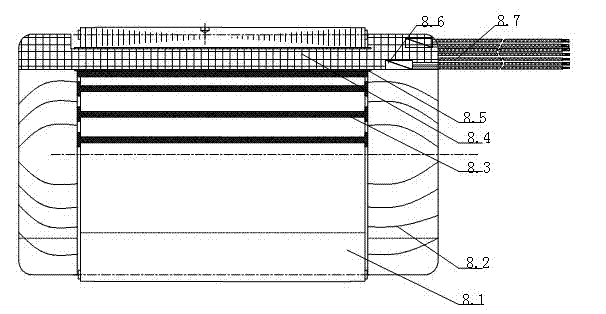

[0032] Same as embodiment 1, except that the upper bearing assembly (6) includes bearing housing outer ring 5.1, bearing housing inner ring 5.3 is fixed in the inner cavity of bearing housing outer ring 5.1, bearing housing outer ring 5.1 and bearing housing inner ring The gap between 5.3 is provided with water circulation tank 5.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com