Macro/micro two-dimensional displacement platform

A technology of two-dimensional displacement and displacement, which is applied in the field of precision engineering, can solve problems such as the increase of the overall volume of the platform, the unfavorable precise positioning of the platform, and the reduction of the overall rigidity of the platform, and achieve the effect of simple structure of the platform, no need for lubrication, and no mechanical friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

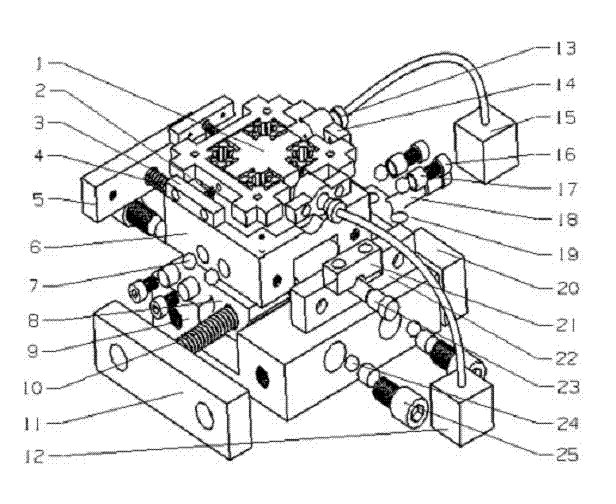

[0016] invented workbenches such as image 3 As shown, including micro-motion platform 1, micro-motion platform reset spring 2, micro-motion platform baffle 3, macro-motion platform reset upper spring 4, macro-motion platform rear baffle 5, macro-motion platform 6, macro-motion platform X-direction guide Steel ball 7, cross slider 8, base body 9, macro-moving platform reset lower spring 10, base body rear baffle plate 11, X direction hydraulic oil power source 12, joint and oil pipe 13, hydraulic micro-driver 14, Y direction hydraulic oil power source 15. X-direction adjusting bolt 16, hemispherical bushing 17, Y-direction micrometer 18, substrate front baffle clamp 19, substrate front baffle 20, macro-motion platform front baffle clamp 21, macro-motion platform front baffle 22 , X-direction micrometer 23, macro-moving platform Y-direction steel ball 24, Y-direction adjusting bolt 25.

[0017] The macro-motion platform 6 is connected to the cross slider 8 through th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com