Gas stripping precipitated calcium carbonate carbonation reactor

A technology of precipitated calcium carbonate and reactor, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of difficult control of the carbonation reaction process, low product quality, high cost, etc., and achieve simple design, prolonged residence time, and improved The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

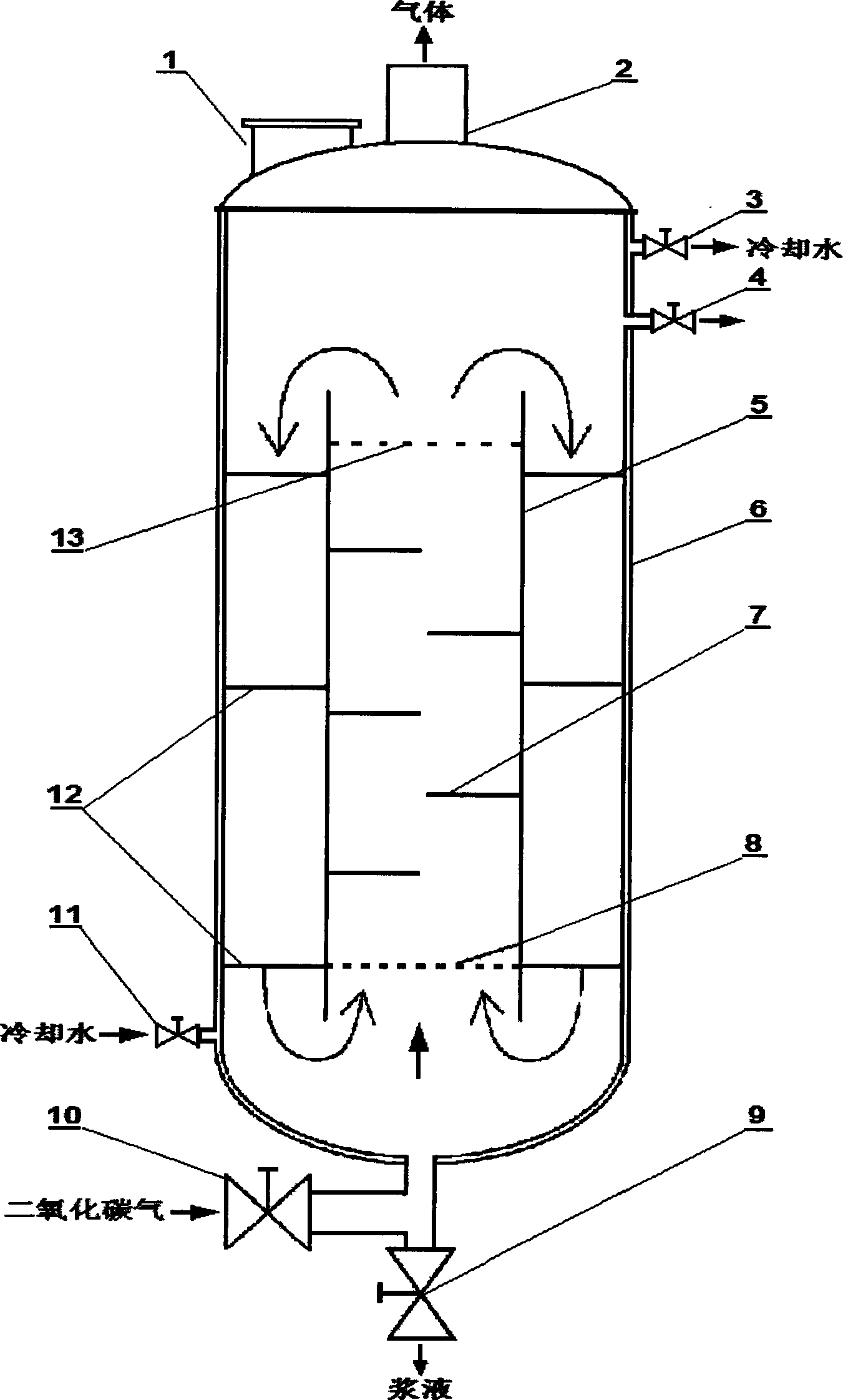

[0038] like figure 1, an air-lifting precipitated calcium carbonate carbonation reactor, mainly composed of an air-lifting guide tube 5, a reactor shell 6, a baffle plate 7 and a lower gas distributor 8; a baffle is set in the middle of the cylindrical air-lifting guide tube 5 Plate 7, lower gas distributor 8 and upper gas distributor 13 are respectively arranged at the upper and lower ends of the gas lift guide tube, the gas distributors 8 and 13 are sieve plates with evenly distributed small holes, and 16 gas lift guide tubes are arranged on the air lift guide tube 5 The cylinder support rod 12 is fixed in the middle of the reactor shell 6; the cylindrical reactor shell 6 and the bottom of the arc-shaped reactor at the lower end are provided with jackets, and the upper and lower ends of the jacket of the cylindrical reactor shell 6 are respectively provided with water outlets. Valve 3 and water inlet valve 11 are the inlet valve, and an overflow valve 4 communicating with th...

Embodiment 2

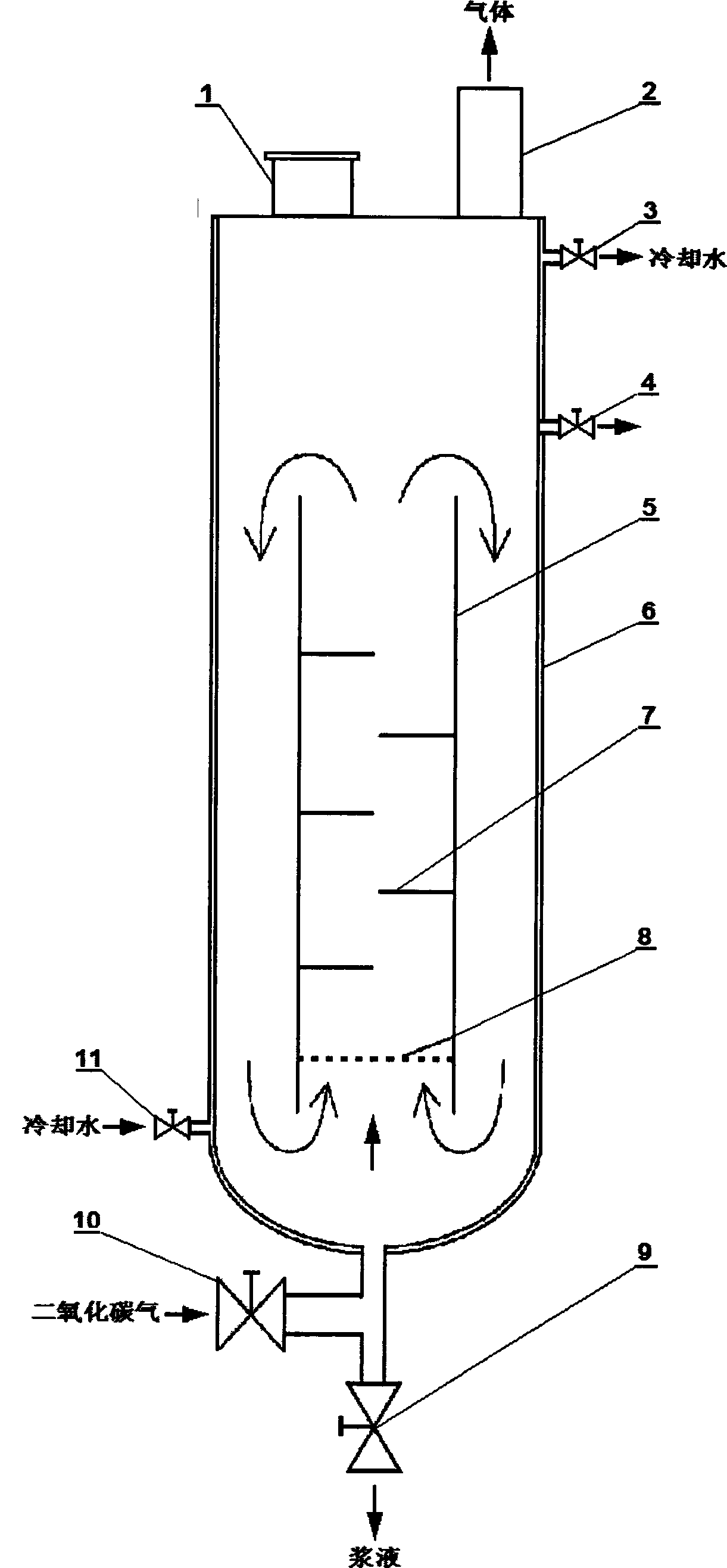

[0041] like figure 2 , an air-lifting precipitated calcium carbonate carbonation reactor, mainly composed of an air-lifting guide tube 5, a reactor shell 6, a baffle plate 7 and a lower gas distributor 8; a baffle is set in the middle of the cylindrical air-lifting guide tube 5 Plate 7, the lower end of the air-lift guide cylinder is provided with a lower gas distributor 8 with evenly distributed small holes, and the air-lift guide cylinder 5 is provided with 12 air-lift guide cylinder support rods 12 fixed in the middle of the reactor shell 6; the cylindrical reactor shell Body 6 and the bottom of the arc-shaped reactor at the lower end are provided with a jacket, and the upper and lower ends of the jacket of the cylindrical reactor shell 6 are respectively provided with a water outlet valve 3 and an inlet valve 11. An overflow valve 4 communicating with the inside of the reactor is set at any position on the periphery of the reactor between the upper ports of the cylinder 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com