Underground mine water treatment method

A treatment method and mine water technology, applied in the field of environmental engineering, can solve the problems of large area of mine water treatment facilities, long hydraulic retention time in sedimentation tanks, large investment in power equipment and pipelines, etc., so as to improve the technical level of resource utilization. , reduce energy consumption and the amount of chemical agents, and solve the effect of water shortage in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

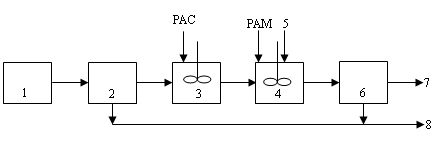

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

[0015] The underground treatment method of mine water in the present invention: the mine water in the underground water tank 1 is pumped into the swirl desanding tank 2 by a pump, the mine water rotates at a fast speed along the tangential direction to generate centrifugal force, and under the action of centrifugal force and gravity , the coarser particulate matter sinks into the sand bucket along the pool wall to be removed; the mine water from which the particulate matter is removed is introduced into the coagulation reaction tank 3, and 10mg / l Inorganic flocculant (PAC), and stirred at a stirring speed of 200 rpm, the coagulation reaction forms alum flowers, the mine water after the coagulation reaction is introduced into the mixing tank 4, and 0.5mg / l organic coagulation aid (PAM) and 1.5g / l The particle size is 70-150 mesh fly ash or coal gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com