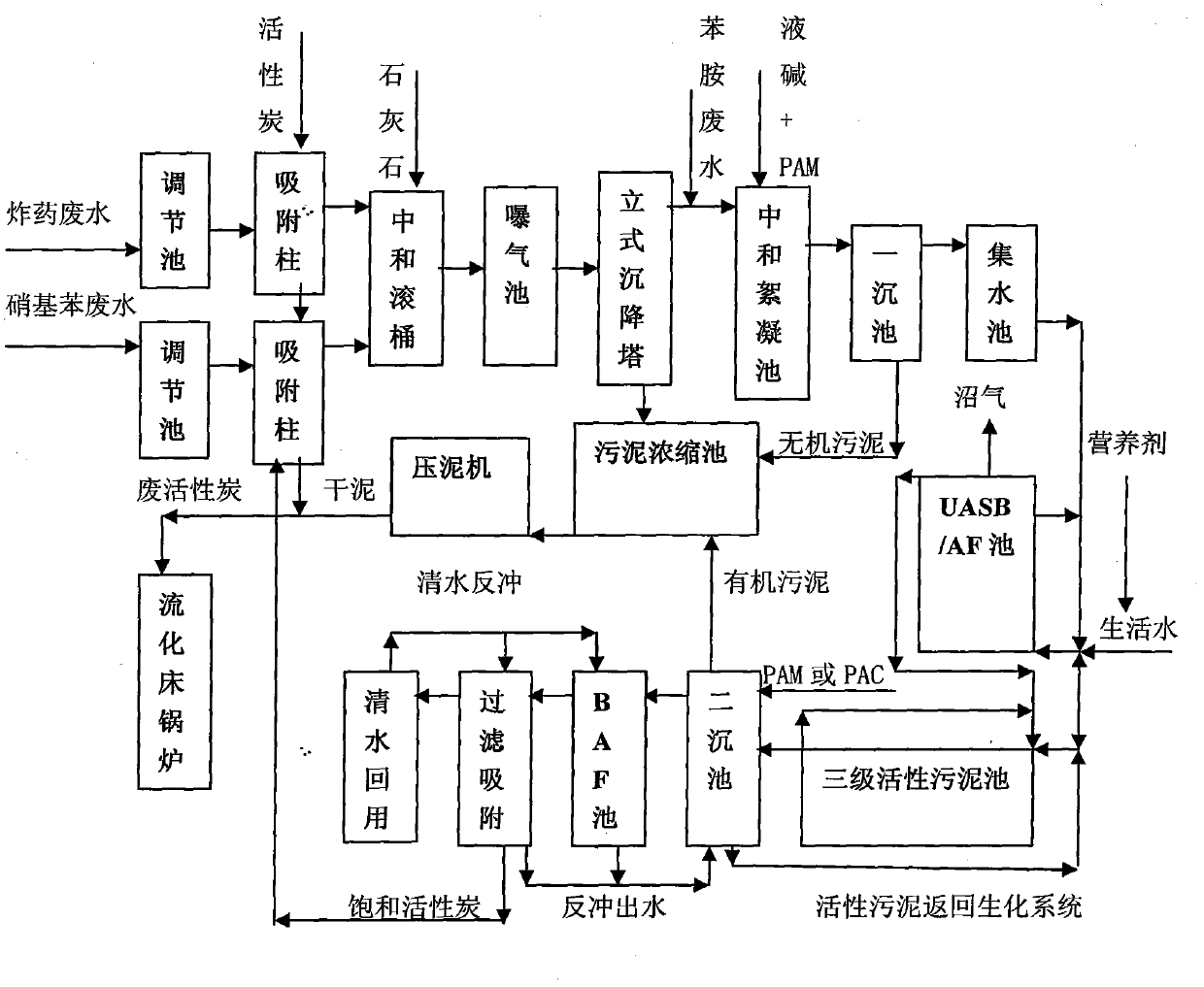

Mixed treatment method of explosive waste water and nitrobenzene and aniline waster water

A technology for nitrobenzene wastewater and explosive wastewater, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of low concentration of microbial tolerance and slow degradation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the mixed wastewater treatment embodiment. The spirit and scope of the present invention disclosed above are not limited by the examples.

[0029] best practice

[0030] Wastewater from multiple explosive production lines enters the adjustment tank and adsorption column at a rate of 15-20 tons per hour, and each adsorption column contains about 7 tons of activated carbon, a total of 3 sets; nitrobenzene wastewater from a 200kt / a dinitrotoluene plant 20-25 tons / hour enters the adjustment tank and adsorption column, each adsorption column contains about 7 tons of activated carbon, a total of 3 sets; mixed wastewater enters the neutralization drum, aeration tank, and vertical sedimentation at 35-45 tons / hour The amount of limestone added to the tower and neutralization drum is 2.8 tons / day, a total of 3 sets; the effluent is combined with the aniline wastewater from the 100kt / a toluene diisocyanate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com