Synthesizing method of N-methoxyphenyl-N-(acetyl)methylamine

The technology of a methoxyphenyl group and a synthetic method, which is applied in the field of pharmaceutical intermediate synthesis, can solve the problems of complicated process, solvent toxicity, unsuitability for industrial production and the like, and achieves the effect of simple process and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

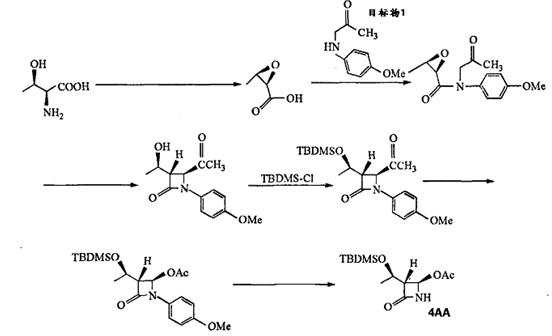

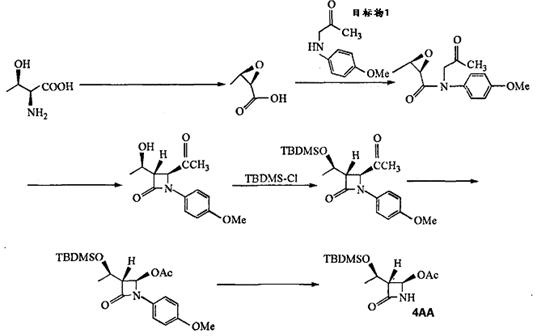

Image

Examples

Embodiment 1

[0035] A kind of synthesis technique of 4-acetoxy azetidinone intermediate is carried out according to the following steps:

[0036]Add 102g (0.83mol) of p-aminoanisole, 184g of ethyl acetate, and 122g of triethylamine into a 1000mL four-necked bottle, stir while heating up in a water bath, when the internal temperature rises to 65°C, keep the constant temperature, and use a funnel to Quickly add 92.5g (1 mol) of chloroacetone, keep reflux for 30min, then add 305g of water to terminate the reaction.

[0037] After static separation, the lower aqueous phase was discarded, 305g of petroleum ether was added to the organic phase, placed in a low-temperature water tank, cooled to -10°C, and stirred for 1 to 2 hours to grow crystals.

[0038] After suction filtration, the filter cake was rinsed with 10 g of petroleum ether, then with 30 g of water, and filtered to dryness by suction to obtain a light yellow crystal of N-methoxyphenyl-N-(acetyl)methylamine.

[0039] The product yiel...

Embodiment 2

[0041] A kind of synthesis technique of 4-acetoxy azetidinone intermediate is carried out according to the following steps:

[0042] Add 102g (0.83 mol) of p-aminoanisole, 184g of ethyl acetate, and 122g of triethylamine into a 1000mL four-necked bottle, stir while heating up in a water bath, when the internal temperature rises to 65°C, keep the constant temperature, slowly Add 92.5g (1 mol) of chloroacetone, dropwise within 30min, keep warm and reflux for 30min, add 305g of water to terminate the reaction.

[0043] After static separation, the lower aqueous phase was discarded, 305g of petroleum ether was added to the organic phase, placed in a low-temperature water tank, cooled to -10°C, and stirred for 1 to 2 hours to grow crystals.

[0044] After suction filtration, the filter cake was rinsed with 10 g of petroleum ether, then with 30 g of water, and filtered to dryness by suction to obtain a light yellow crystal of N-methoxyphenyl-N-(acetyl)methylamine.

[0045] The prod...

Embodiment 3

[0047] A kind of synthesis technique of 4-acetoxy azetidinone intermediate is carried out according to the following steps:

[0048] Add 148g (1.2mol) of p-aminoanisole, 197g of ethyl acetate, and 99g of triethylamine into a 1000mL four-necked bottle, stir while heating up in a water bath, when the internal temperature rises to 85°C, keep the constant temperature, slowly Add 100g (1.08mol) of chloroacetone, dropwise within 40min, keep warm and reflux for 60min, add 296g of water to terminate the reaction.

[0049] After static separation, the lower aqueous phase was discarded, 592g of petroleum ether was added to the organic phase, placed in a low-temperature water tank, the temperature was lowered to 0°C, and the crystal was grown by stirring for 1-2 hours.

[0050] After suction filtration, the filter cake was rinsed with 15g of petroleum ether, then with 45g of water, and filtered to dryness by suction to obtain a light yellow crystal of N-methoxyphenyl-N-(acetyl)methylamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com