Preparation method of photosensitive hydrogel

A hydrogel and photosensitivity technology, applied in the field of intelligent polymer materials and intelligent polymer hydrogels, can solve the problems of large differences in product properties, difficult product molecular weight and molecular weight distribution, and insufficient light responsiveness. Achieving the effect of good responsiveness, easy control, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

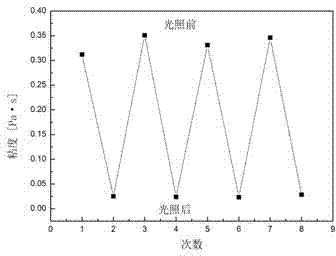

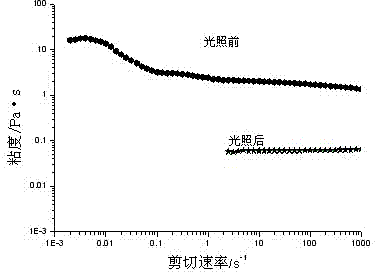

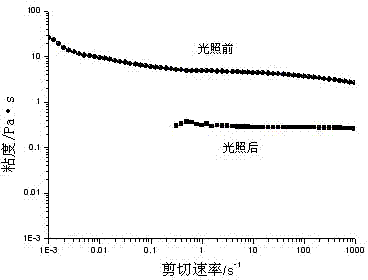

[0025] Step a: According to the mass ratio of polyacrylic acid and N-methyl-2-pyrrolidone is 1:25, polyacrylic acid is dissolved in N-methyl-2-pyrrolidone at 60 ° C, and then p-aminoazobenzene is The mass ratio of polyacrylic acid is 0.2:1, and the dehydrating agent biscyclohexylcarbimide is added according to the molar ratio of p-aminoazobenzene and biscyclohexylcarbimide at 1:1, and the reaction is stirred at 60°C for 48 hours. Add 30% sodium hydroxide aqueous solution to the reacted substance according to the volume ratio of sodium hydroxide aqueous solution and N-methyl-2-pyrrolidone as 1:1, and precipitate after stirring, and filter the solid with 60°C N -Methyl-2-pyrrolidone was washed twice, and the amount used was the same as the volume of the aqueous sodium hydroxide solution. The obtained solid was washed 3 times with methanol, dissolved in deionized water, dialyzed with deionized water, and freeze-dried to obtain the target product azobenzene-modified polyacrylic ac...

Embodiment 2

[0029] Step a: Dissolve polyacrylic acid in N-methyl-2-pyrrolidone at 65°C at a mass ratio of polyacrylic acid to N-methyl-2-pyrrolidone of 1:30, and then add p-aminoazobenzene to The mass ratio of polyacrylic acid is 0.3:1, and the dehydrating agent biscyclohexylcarbimide is added according to the molar ratio of p-aminoazobenzene and biscyclohexylcarbimide at 1:1.1, and the reaction is stirred at 65°C for 72 hours. Add 35% aqueous sodium hydroxide solution to the reacted substance according to the volume ratio of aqueous sodium hydroxide solution to N-methyl-2-pyrrolidone at 1.2:1, and precipitate after stirring, and filter the solid with 65°C N -Methyl-2-pyrrolidone was washed 3 times, and the amount used was the same as the volume of the aqueous sodium hydroxide solution. The obtained solid was washed twice with methanol, dissolved in deionized water, dialyzed with deionized water, and freeze-dried to obtain the target product azobenzene-modified polyacrylic acid.

[0030]...

Embodiment 3

[0033] Step a: dissolving polyacrylic acid in N-methyl-2-pyrrolidone at 70°C at a mass ratio of polyacrylic acid to N-methyl-2-pyrrolidone is 1:35, and then p-aminoazobenzene is The mass ratio of polyacrylic acid is 0.5:1, and the dehydrating agent biscyclohexylcarbimide is added according to the molar ratio of p-aminoazobenzene and biscyclohexylcarbimide as 1:1.2, and the reaction is stirred at 70°C for 96 hours. Add 35% sodium hydroxide aqueous solution to the reacted substance according to the volume ratio of sodium hydroxide aqueous solution and N-methyl-2-pyrrolidone as 1.2:1, after stirring, precipitate is obtained, and after suction filtration, the solid is washed with 70 ° C N -Methyl-2-pyrrolidone was washed twice, and the amount used was the same as the volume of the aqueous sodium hydroxide solution. The obtained solid was washed three times with methanol, dissolved in deionized water, dialyzed with deionized water, and freeze-dried to obtain the target product azob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com