Sodium alginate-based slurry, printing sizing agent and preparation methods thereof

A technology of sodium alginate and printing paste, which is applied in dyeing, textiles, and papermaking. It can solve the problems of rough lines, high viscosity of color paste, and the appearance quality of fabrics that affect printing production efficiency, so as to improve production efficiency and Economic benefit, quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

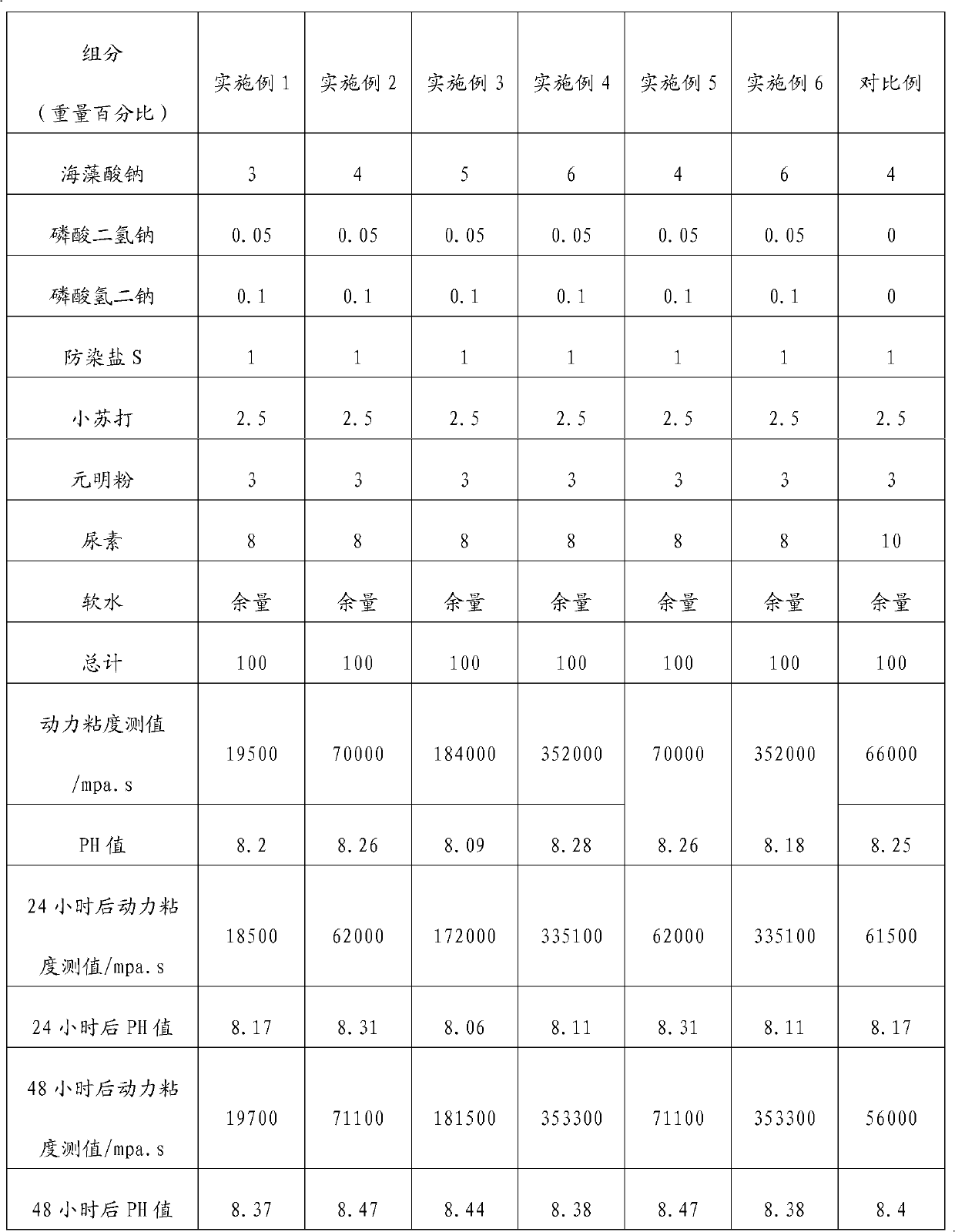

[0040] The present invention is further elaborated below by embodiment:

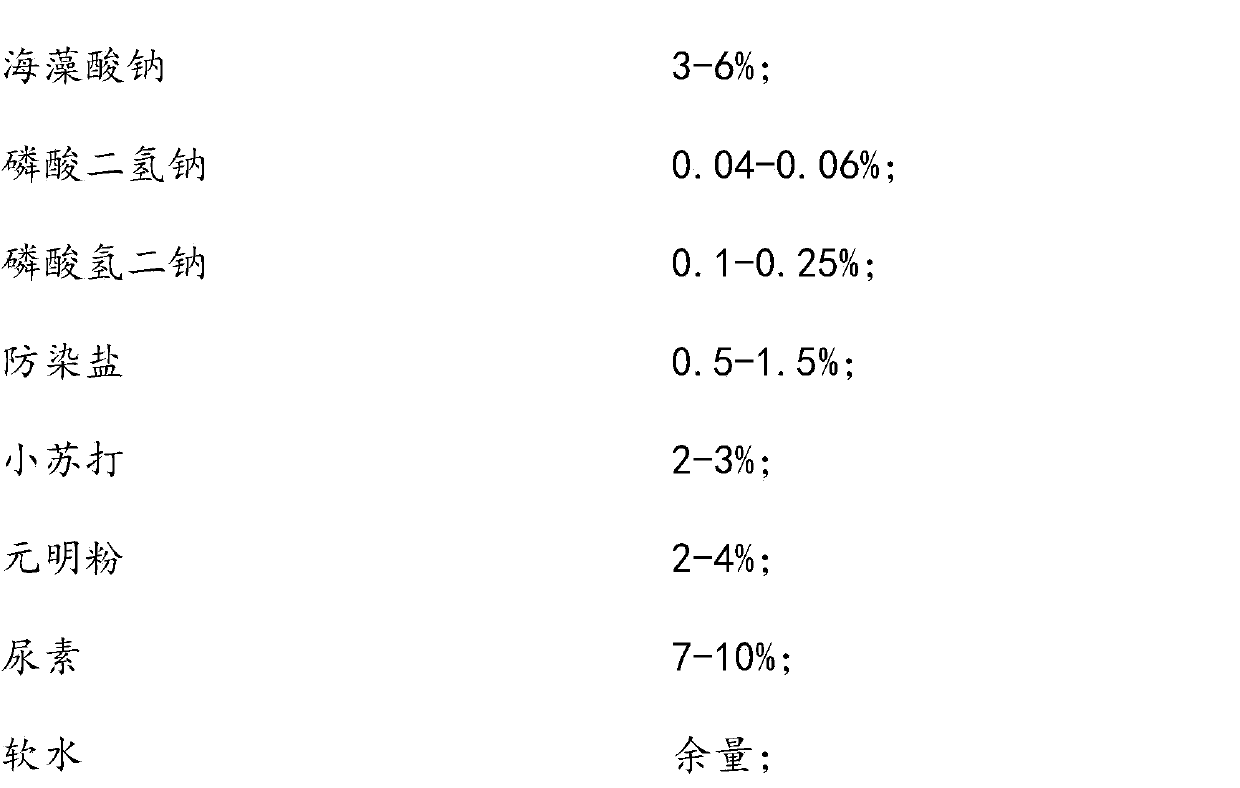

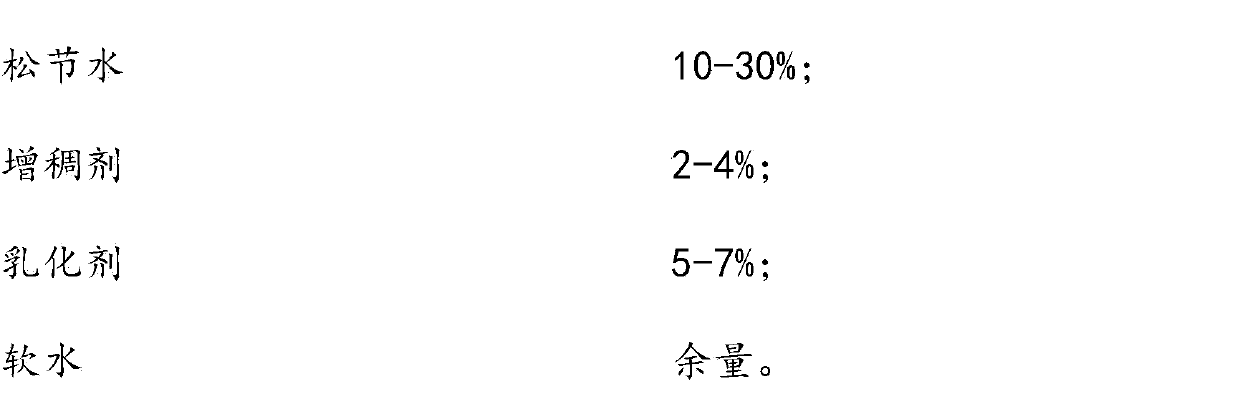

[0041] In the following examples, sodium alginate is used as the main ingredient of printing paste, and the reactive dye is dyed to the carrier of cellulose fiber. When the aqueous solution of sodium alginate is at a mass-volume concentration of 50g / L, the dynamic viscosity is 150pa.s-200pa. s, product of Qingdao Jiejing; the function of sodium dihydrogen phosphate and disodium hydrogen phosphate is to prevent the hydrolysis of reactive dyes in the dissolved state, and the product of Jinghong Instrument Co., Ltd.; the function of anti-staining salt S is to prevent reactive dyes from The function of dyeing to maintain the reactive groups of dyes, Shangyu Hongsheng Chemical Products; baking soda as an alkaline agent to ensure that reactive dyes dye cellulose fibers under alkaline conditions, Yuxing Chemical Products; the role of Yuanming powder is to make Dyeing and fixing of reactive dyes to cellulose fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com