Automatic dredging system for underground storage-capacity-regulating pipe culvert

An automatic technology for regulating and storing pipes, which is applied in waterway systems, machines/engines, and mechanisms that generate mechanical power, etc. It can solve the problem of reducing the effective regulating and storing volume of regulating and storing pipes and culverts, silting up regulating and accumulating pipes and culverts, and restricting deep down-storing. The promotion and application of pipes and culverts can achieve good energy conversion and energy utilization efficiency, reduce erosion damage, and achieve good dredging effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

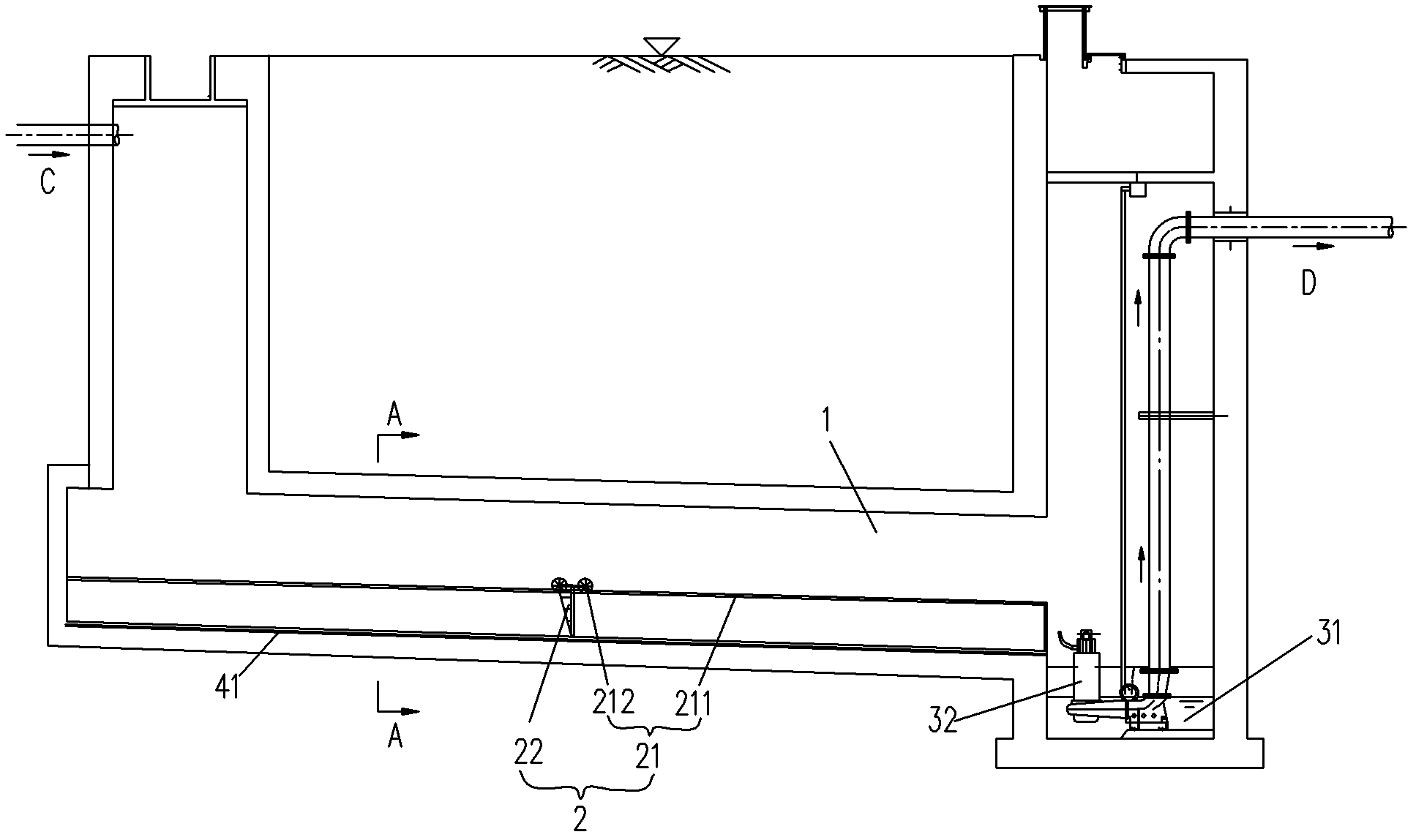

[0028] like figure 1 As shown in the regulation and storage pipe culvert 1 located deep in the ground, the inflow sewage flows into the regulation and storage pipe culvert 1 from point C, after regulation and storage, it is discharged from point D and enters the sewage pipe network. During this process, the sludge will settle at the bottom of the regulation and storage pipe culvert 1 .

[0029] The automatic desilting system of the underground regulating and storage pipe culvert of the present invention is used to clean up the silt, and mainly includes a slidable desilting device 2 and an aeration system arranged in the regulating and storing pipe culvert 1 1 The silt discharge tank 31 and the sewage pump 32 at the end.

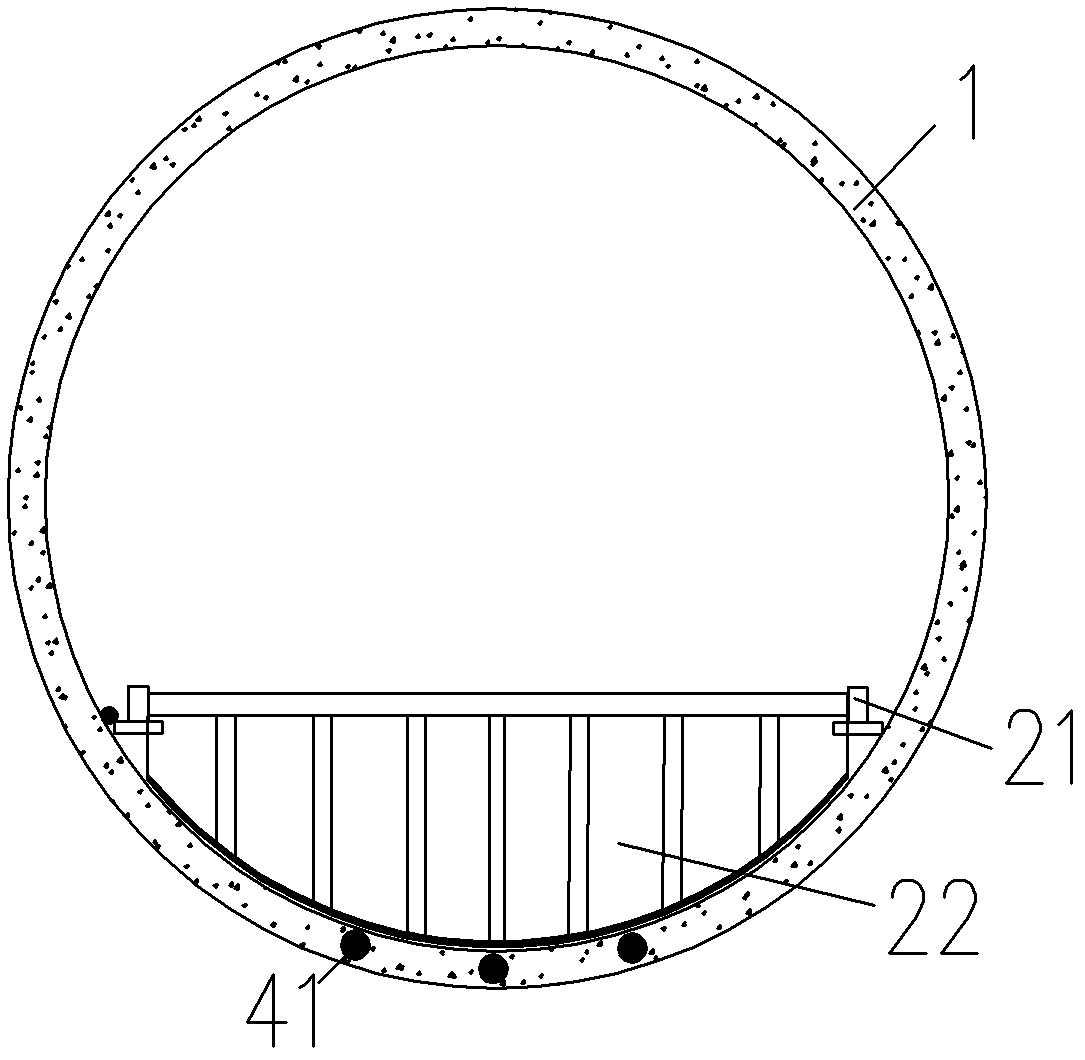

[0030] The desilting device 2 includes a sliding component 21 that can be displaced in the regulation and storage pipe culvert 1 , and a fender 22 fixed to the sliding component 21 .

[0031] Specifically, in this embodiment, the sliding assembly 21 include...

Embodiment 2

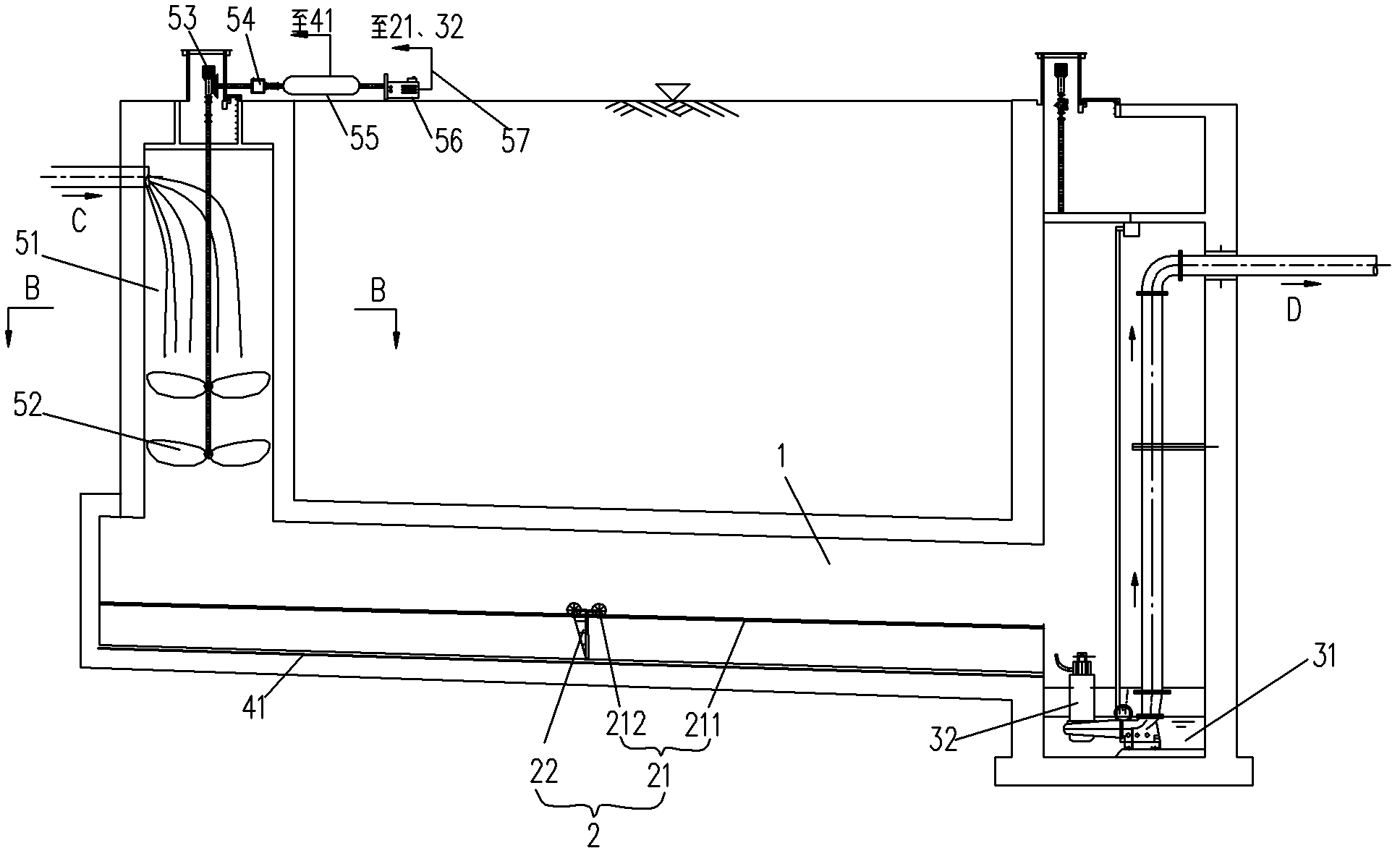

[0040] like image 3 , Figure 4 As shown, this embodiment is a further optimization of Embodiment 1. On the basis of the dredging device and the aeration system, a drop water energy storage device is added. The falling water energy storage device mainly includes a one-stage impeller 52 arranged at the bottom of the falling water shaft 51 (in different embodiments, according to different parameters such as head drop and inflow flow, multi-stage impellers can be set to meet energy dissipation requirements). The impeller 52 mainly includes a transmission rod 521 and an impeller 522, which are used to eliminate the potential energy generated by the free fall of rainwater and sewage from a large height, and convert the potential energy into kinetic energy.

[0041] The power output end of the impeller 52 is connected to the power input end of an air compressor 54 via a set of speed change gears 53 , and the air compressor 54 communicates with a compressed air storage tank 55 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com