Variable frequency superconducting microstrip line resonator

A superconducting resonator and microstrip line technology, applied in the microwave field, can solve the problems of large design error, large filter insertion loss, slow frequency conversion response, etc., and achieves a large number of variable frequency points, accurate frequency control, and frequency conversion range. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

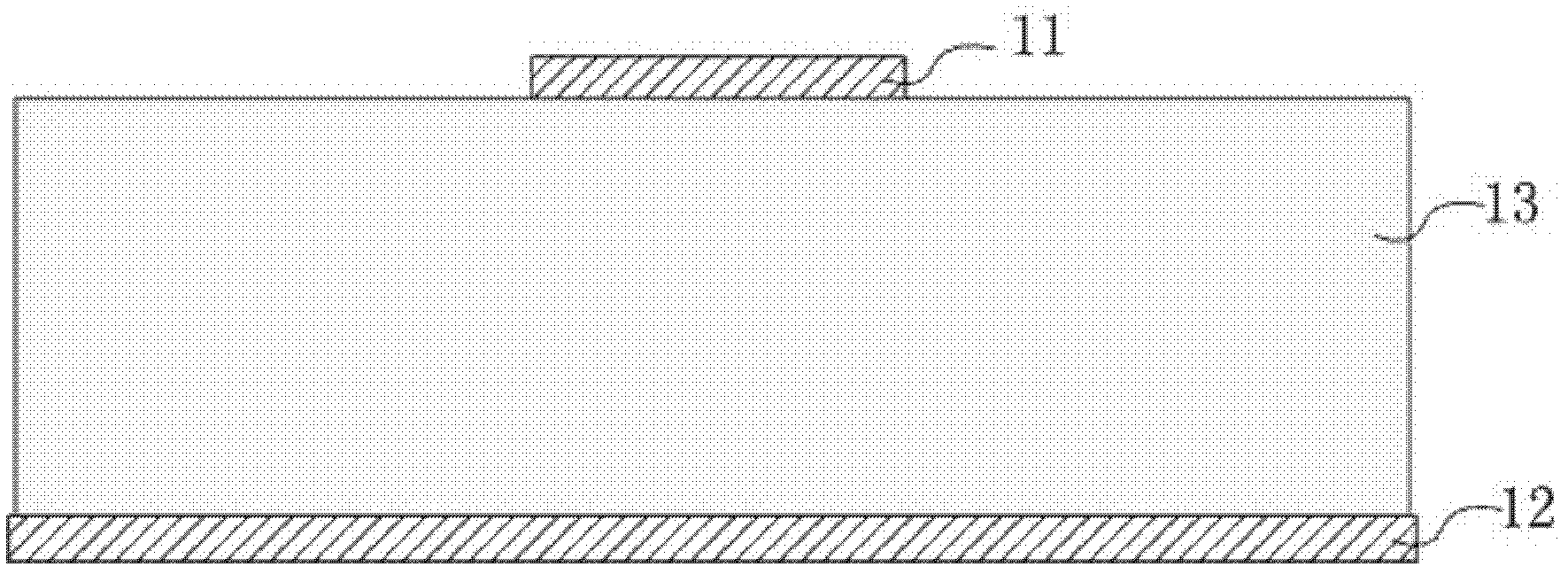

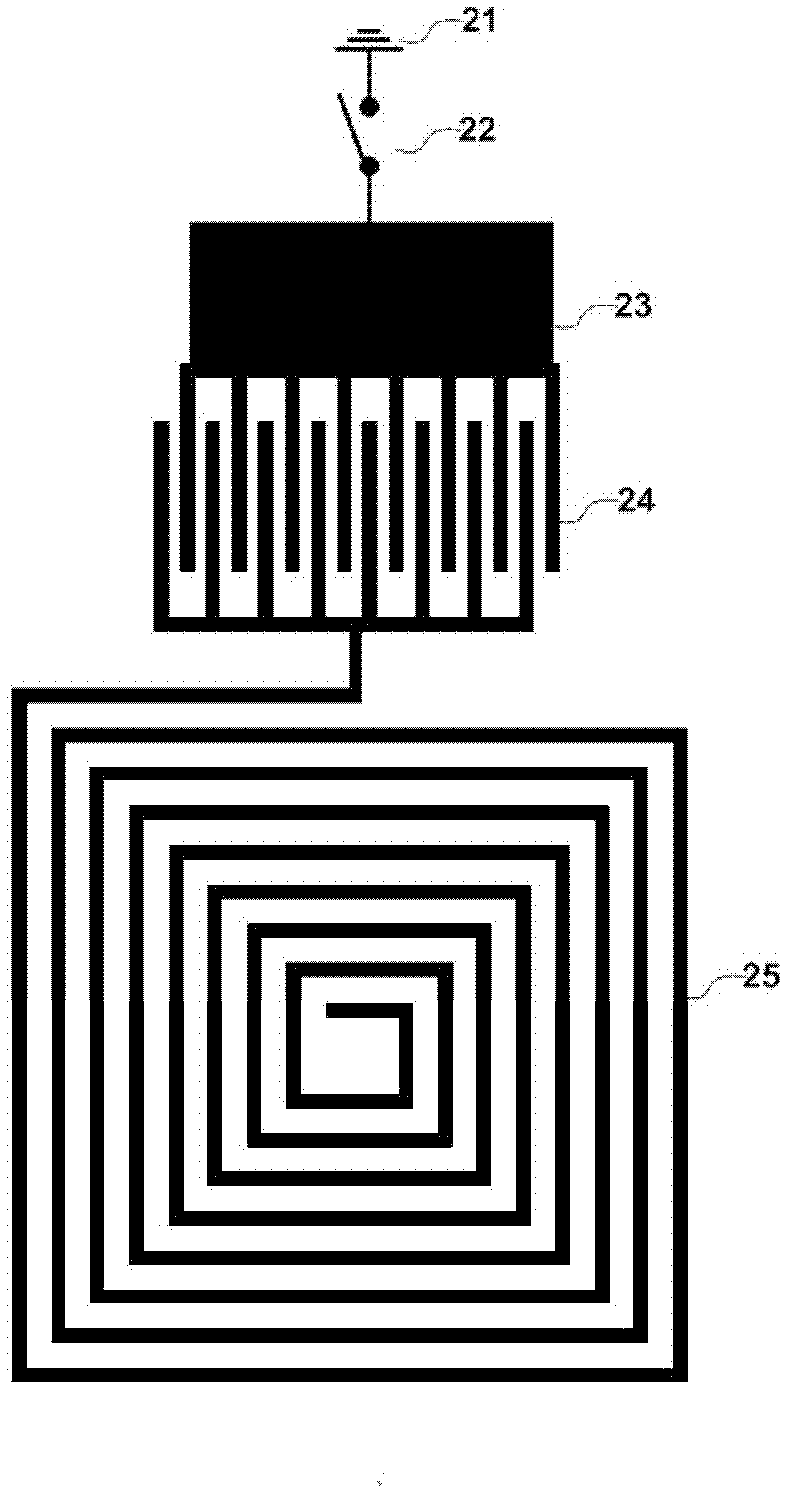

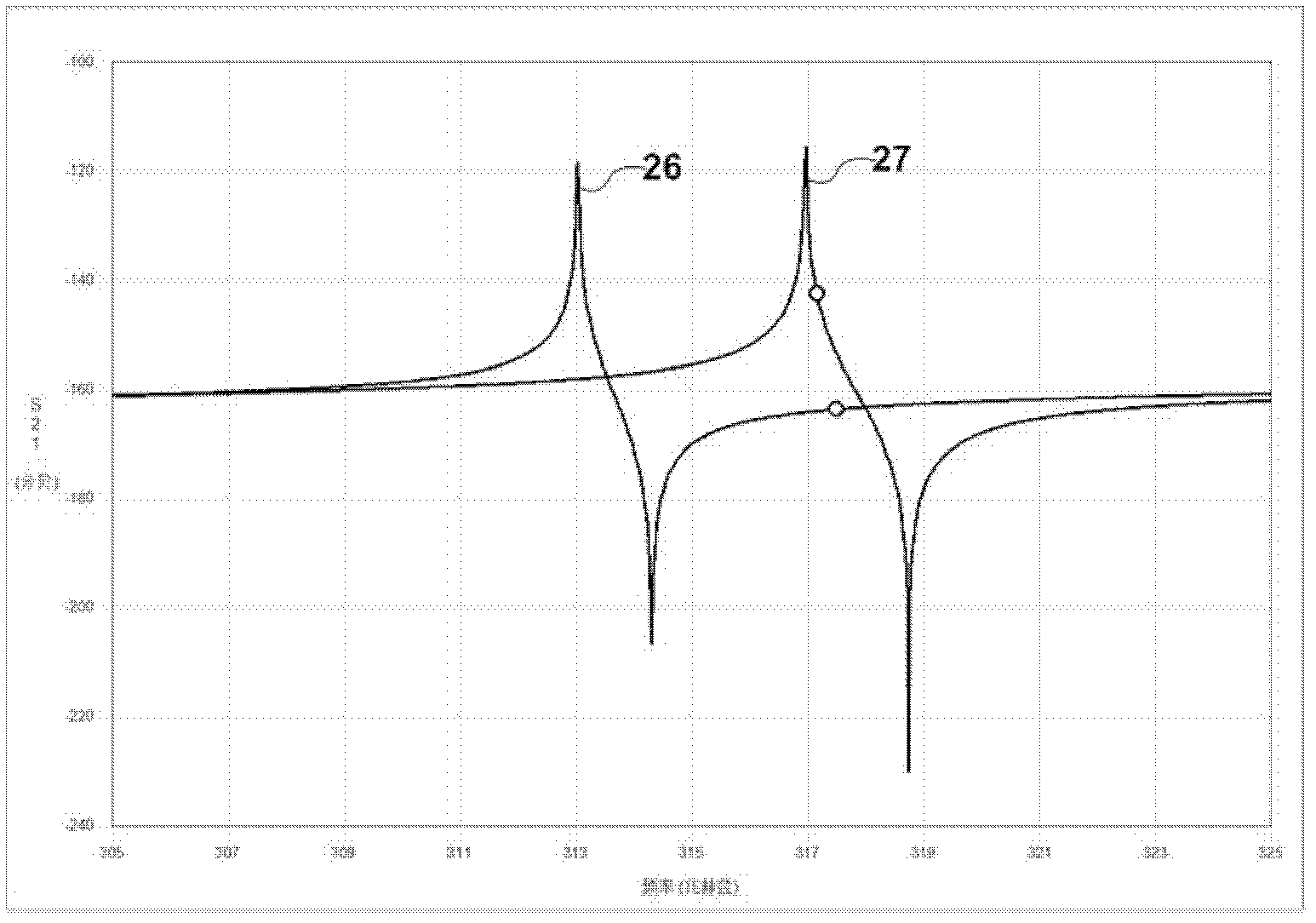

[0045] refer to figure 1 , this embodiment includes an upper superconducting resonator structure, a lower superconducting thin film, and a dielectric substrate between the upper and lower superconductors. The upper layer superconducting resonator structure of the present embodiment is as shown in Figure 2, comprises a continuous single spiral main strip line 25 (using a continuous microstrip line, this microstrip line is a superconducting microstrip line), the main strip The belt line is composed of eight circles in the counterclockwise direction from the outside to the inside. The coils are all rectangular coils. The outer contour of the outermost coil is 8.26mm long, 8.48mm wide, and the line width is 0.16mm. The circles are equally spaced with a pitch of 0.32mm. The outer port of the main strip line and an external microstrip line 23 form an interdigital coupling structure 24, the interdigital length is 2.4mm, the width is 0.16mm, the number of interdigital roots is 8, the...

no. 2 example

[0049] refer to figure 1 , this embodiment includes an upper superconducting resonator structure, a lower superconducting thin film, and a dielectric substrate between the upper and lower superconductors. The upper superconducting resonator structure of this embodiment is as follows Figure 3a As shown, it includes a continuous single-helical main stripline 37 (using a continuous microstrip line, which is a superconducting microstrip line), and the main stripline circles eight times in a counterclockwise direction from the outside to the inside. Composition, the coils are all rectangular coils, the outer contour of the outermost coil is 8.26 mm long, 8.48 mm wide, and the line width is 0.16 mm, and the adjacent coils are equally spaced and the distance is 0.32 mm. The outer port of the main strip line and two external microstrip lines (using a continuous microstrip line, the microstrip line is a superconducting microstrip line) form interdigital coupling structures 35 and 36 ...

no. 3 example

[0053] refer to figure 1 , this embodiment includes an upper superconducting resonator structure, a lower superconducting thin film, and a dielectric substrate between the upper and lower superconductors. The upper superconducting resonator structure of this embodiment is as follows Figure 4 As shown, it includes a continuous anti-cis-helical main strip line 45 (using a continuous microstrip line, which is a superconducting microstrip line), and the main strip line surrounds from the outside to the inside along the counterclockwise direction Four circles, and then four circles clockwise. The coils are all rectangular coils. The outer contour of the outermost coil is 8mm long, 8mm wide, and the line width is 0.16mm. The adjacent coils are equally spaced and the spacing is 0.24. mm. The external port of the main strip line and the four external microstrip lines 43 form an interdigital coupling structure 44 . The finger length of the finger coupling structure 44 is 2.4mm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com