Sustained-release penicillin anion intercalation hydrotalcite material as well as preparation and application thereof

An anion intercalation, hydrotalcite technology, applied in the field of antibacterial, can solve the problems of poor photothermal stability and easy inactivation, and achieve the effect of improving photothermal stability and inhibiting microbial fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

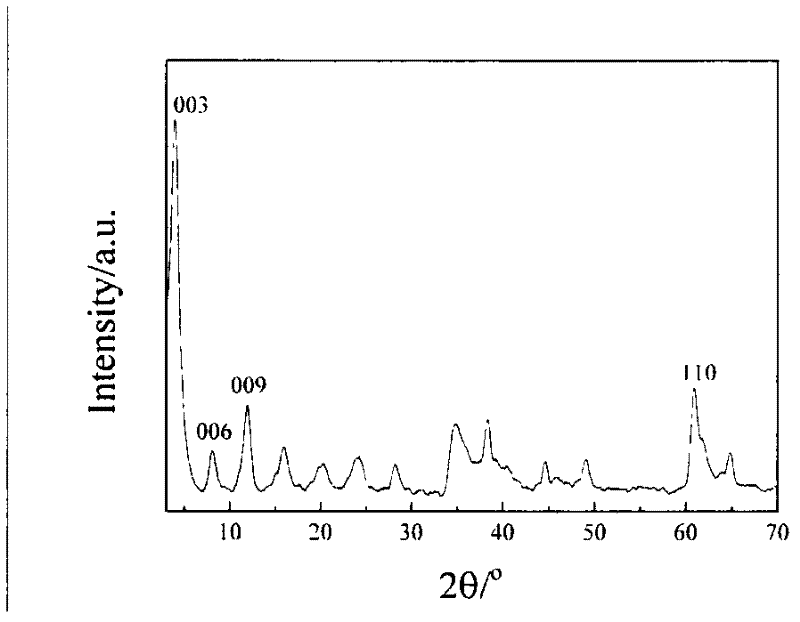

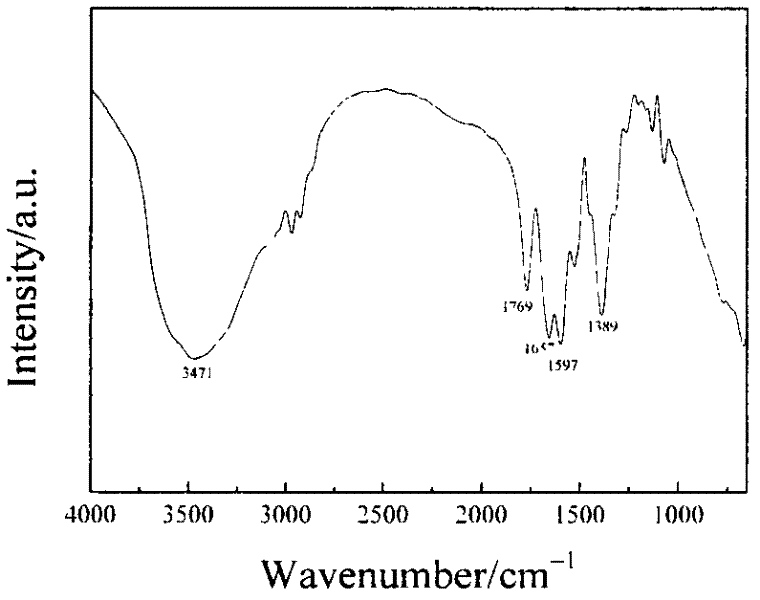

[0025] The general formula of the chemical composition of the antibacterial material is [M 2+ 1-x m 3+ x (OH) 2 ] x+ (C 16 h 17 N 2 o 4 S - ) x ·nH 2 O, M 2+ Represents the divalent metal ion Mg 2+ ,M 3+ Represents trivalent metal ion Al 3+ ; 2+ / M 3+ The molar ratio of is 2; x is 0.33.

[0026] Preparation Process:

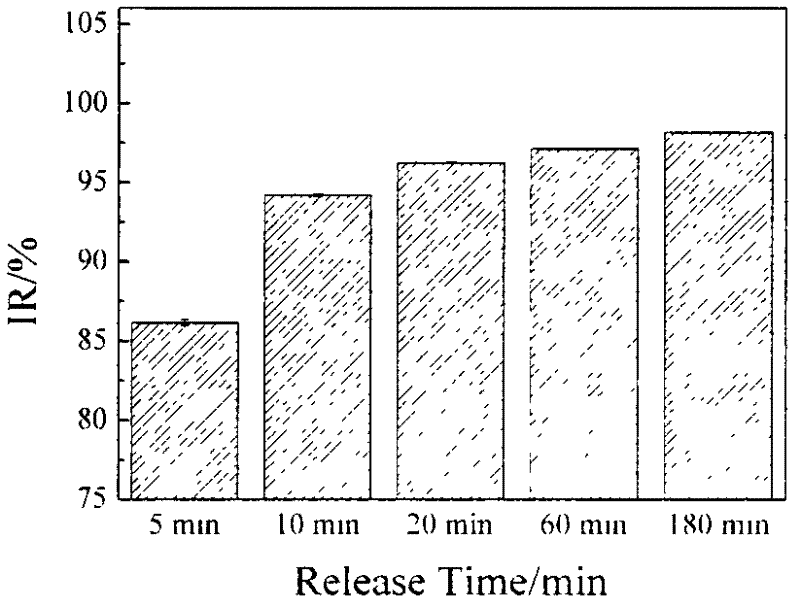

[0027] The experimental water is the freshly boiled secondary deionized water to remove CO 2 , reacting at N 2 under atmosphere. Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is made into a 0.75mol / L mixed salt solution (Mg 2+ / Al 3+ =2). NaOH is formulated into a 6mol / L alkaline solution. Add the salt solution and the alkali solution into the four-neck flask at the same time, stir vigorously for 30 minutes, filter, wash and transfer the resulting slurry into a reaction kettle for hydrothermal crystallization at 140°C for 10 hours. The whole process was protected by nitrogen gas. The product was cooled, washed, and centrifuged, and 7....

Embodiment 2

[0037] The general formula of the chemical composition of the anti-corrosion material is [M 2+ 1-x m 3+ x (OH) 2 ] x+ (C 16 h 17 N 2 o 4 S - ) x ·nH 2 O, M 2+ Represents the divalent metal ion Mg 2+ ,M 3+ Represents trivalent metal ion Al 3+ ; 2+ / M 3+ The molar ratio of is 3; x is 0.25.

[0038] The experimental water is the freshly boiled secondary deionized water to remove CO 2 , reacting at N 2 under atmosphere. Mg(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is made into a 0.40mol / L mixed salt solution (Mg 2+ / Al 3+ =3). NaOH is made into a 4mol / L alkaline solution. Add the salt solution and the alkali solution to the four-necked flask at the same time and stir vigorously for 40 minutes, then filter, wash and transfer the resulting slurry to a reaction kettle for hydrothermal crystallization at 140°C for 12 hours. The whole process was protected by nitrogen gas. The product was cooled, washed with water, and centrifuged, and 8.0 g of freshly prep...

Embodiment 3

[0040] The general formula of the chemical composition of the anti-corrosion material is [M 2+ 1-x m 3+ x (OH) 2 ] x+ (C 16 h 17 N 2 o 4 S - ) x ·nH 2 O, M 2+ Represents the divalent metal ion Ni 2+ ,M 3+ Represents trivalent metal ion Al 3+ ; 2+ / M 3+ The molar ratio of is 4; x is 0.20.

[0041] The experimental water is the freshly boiled secondary deionized water to remove CO 2 , reacting at N 2 under atmosphere. Ni(NO 3 ) 2 ·6H 2 O and Al(NO 3 ) 3 9H 2 O is made into a 1.00mol / L mixed salt solution (Mg 2+ / Al 3+ =4). NaOH is made into 2mol / L alkaline solution. Add the salt solution and the alkali solution into the four-neck flask at the same time, stir vigorously for 60 minutes, filter, wash and transfer the resulting slurry into a reaction kettle for hydrothermal crystallization at 140°C for 16 hours. The whole process was protected by nitrogen gas. The product was cooled, washed, and centrifuged, and 8.5 g of freshly prepared nitrate-interc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com