Silane bridging luminescent material, preparation method and application thereof, and color developing agent

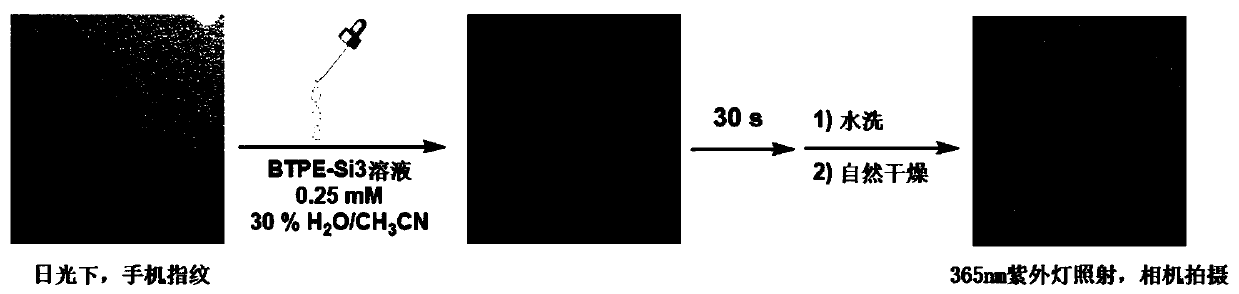

A luminescent material and bridging technology, which is applied in the detection field, can solve the problems of destroying the original state of fingerprints, the inability to repeat the measurement, and the health hazards of the testing personnel, etc., and achieve high-efficiency and high-resolution latent fingerprint imaging, high yield, and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

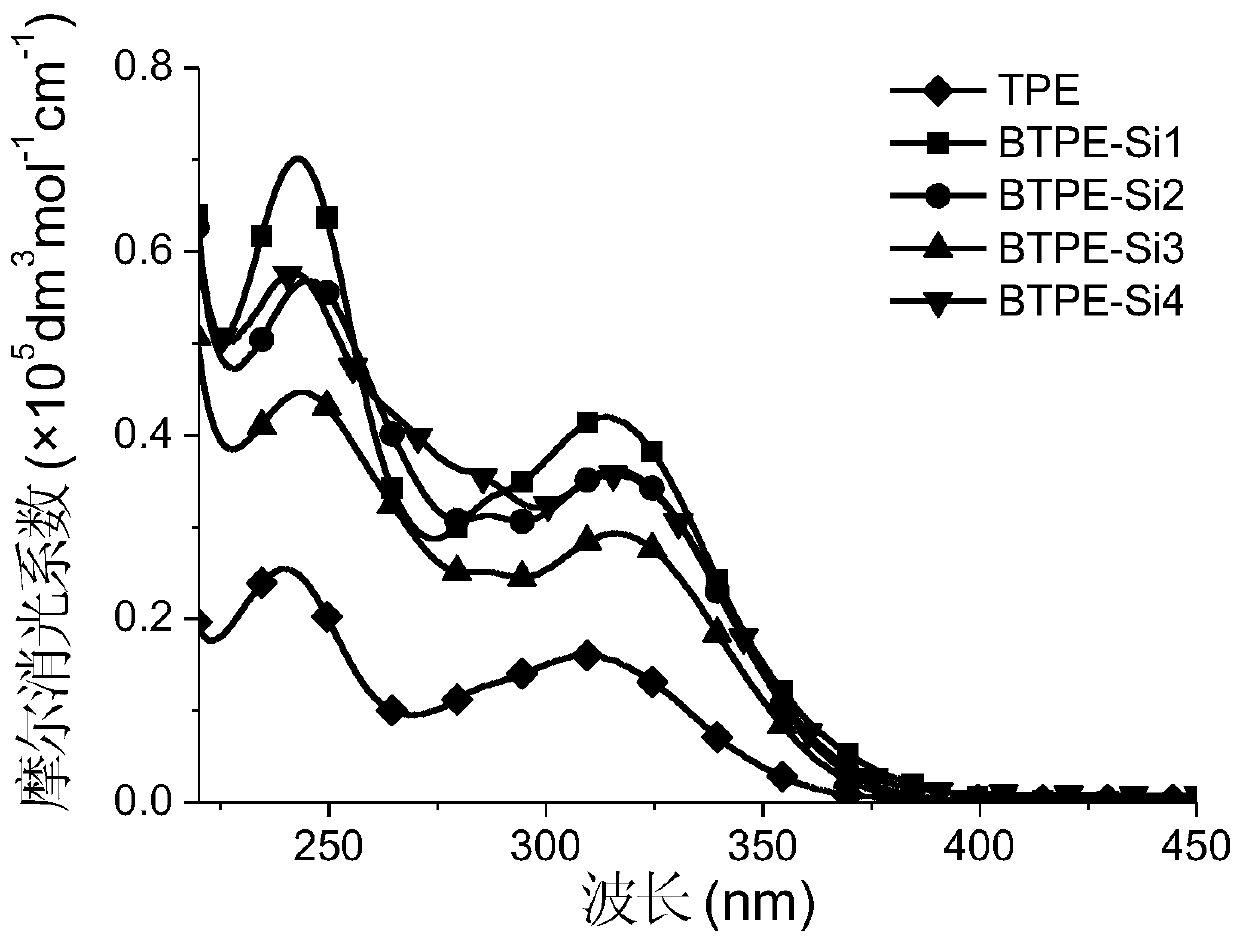

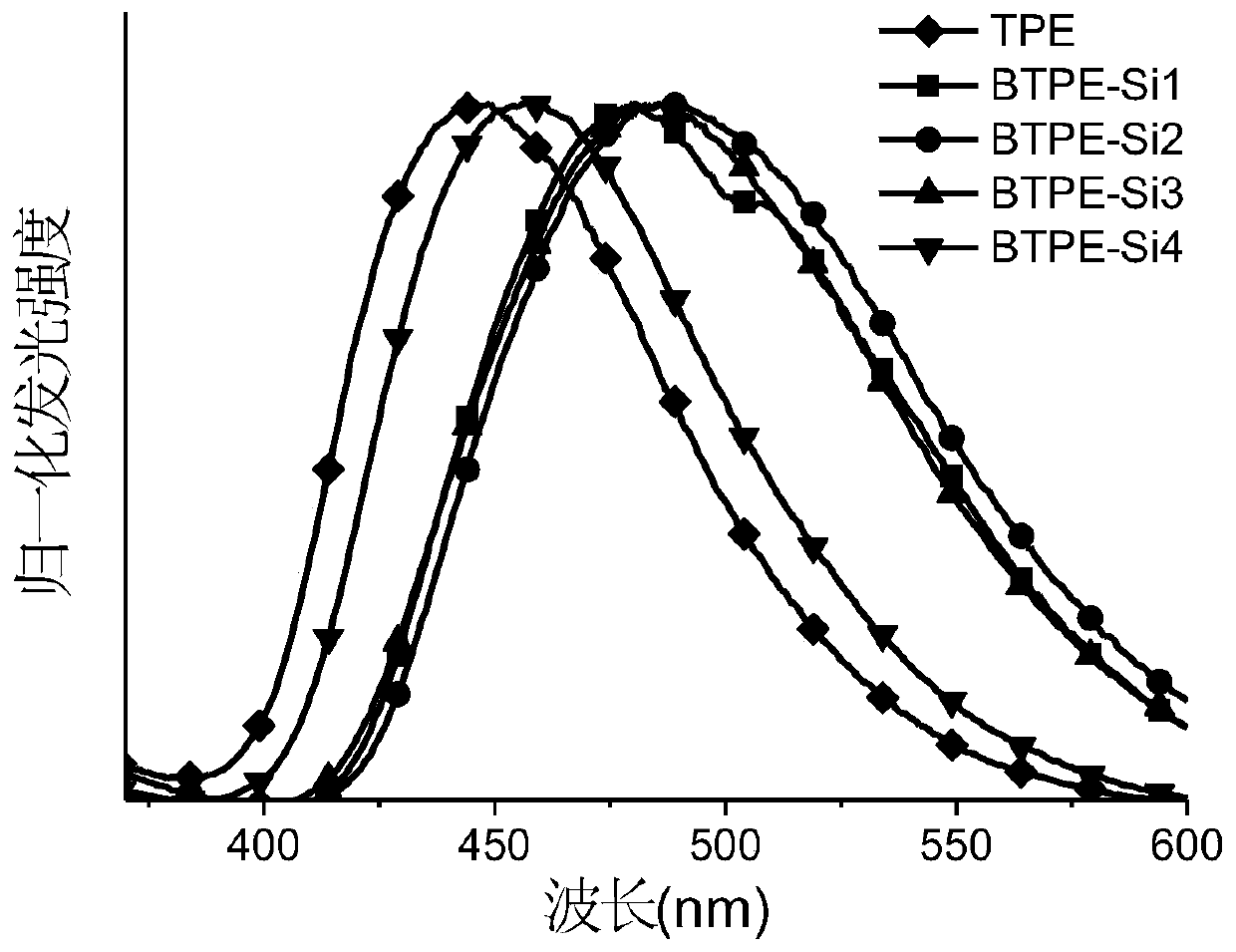

[0053] Preparation of monosilane-bridged bis-tetraphenylethylene luminescent material (BTPE-Si1)

[0054]

[0055] Reaction equation:

[0056]

[0057] (1) Intermediate a" was prepared according to the method reported in the literature (Chem. Commun., 2014, 50, 1725-1727.).

[0058] (2) Under argon protection, add intermediate a" (300mg, 0.73mmol) and 20mL of anhydrous THF into a 100mL Schlenk bottle. Cool to -78°C. Add n-butyllithium solution (0.5mL, 0.8mmol, 1.6 M in n-hexane) was added dropwise to the flask, and the reaction mixture was stirred at -78°C for 3 h, and then dichlorodimethylsilane (44 μL, 0.36 mmol) was added dropwise. After the addition, the mixture was slowly warmed to room temperature and stirred After 2 h, the reaction was completed and the mixture was added to NaHCO 3 In aqueous solution, CH 2 Cl 2 The organic phase was extracted and washed with anhydrous Na 2 SO 4 Dry and remove the solvent by rotary evaporation under reduced pressure. The cr...

Embodiment 2

[0061] Preparation of bis-tetraphenylethylene luminescent material (BTPE-Si2) bridged by bissilane

[0062]

[0063] Reaction equation:

[0064]

[0065] Under argon protection, intermediate a" (300mg, 0.73mmol) and 20mL of anhydrous THF were added to a 100mL Schlenk bottle. Cool to -78°C. n-BuLi solution (0.5mL, 0.8mmol, 1.6M n-hexane solution) was added dropwise to the flask, the reaction mixture was stirred at -78°C for 3h, and then dichlorotetramethyldisilane (64μL, 0.36mmol) was added dropwise. After the addition was complete, the mixture was slowly warmed to room temperature and stirred for 2 hours, the reaction was completed and the mixture was added to NaHCO 3 In aqueous solution, CH 2 Cl 2 The organic phase was extracted and washed with anhydrous Na 2 SO 4 Dry and remove the solvent by rotary evaporation under reduced pressure. The crude product was purified by chromatography on a silica gel column, (CH 2 Cl 2 / PE=1 / 10) as eluent, the product was obtaine...

Embodiment 3

[0068] Preparation of trisilane-bridged bis-tetraphenylethylene luminescent material (BTPE-Si3)

[0069]

[0070] Reaction equation:

[0071]

[0072] (1) Preparation of two (trifluoromethanesulfonyl) hexamethyltrisilane 5a:

[0073] At 0°C, lithium metal (5.0 g, 714 mmol, washed with hexane before use) was added into THF (100 mL), and chlorodimethylphenylsilane 2 (15 mL, 89 mmol) was slowly added dropwise, and the mixture was stirred at 0 °C and stirred overnight. In a flask equipped with a dropping funnel, dichlorodimethylsilane (5.4 mL, 44.5 mmol) was dissolved in THF (150 mL) and cooled to 0°C. Transfer the dark red phenyldimethylsilyl lithium 3 solution to the dropping funnel with a syringe, and then slowly add it dropwise to the dichlorodimethylsilane solution over 5 minutes. After the addition was complete, the reaction mixture was allowed to warm to room temperature and stirred overnight. After the reaction was complete, THF was removed under reduced pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com