Filtering layer back washing method for percolating water abstraction and control system

A control system, backwashing technology, applied in separation methods, chemical instruments and methods, loose filter material filters, etc., can solve problems such as human error, affecting the effect of backwashing, and increasing the labor intensity of staff.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but they are not further limitations on the present invention.

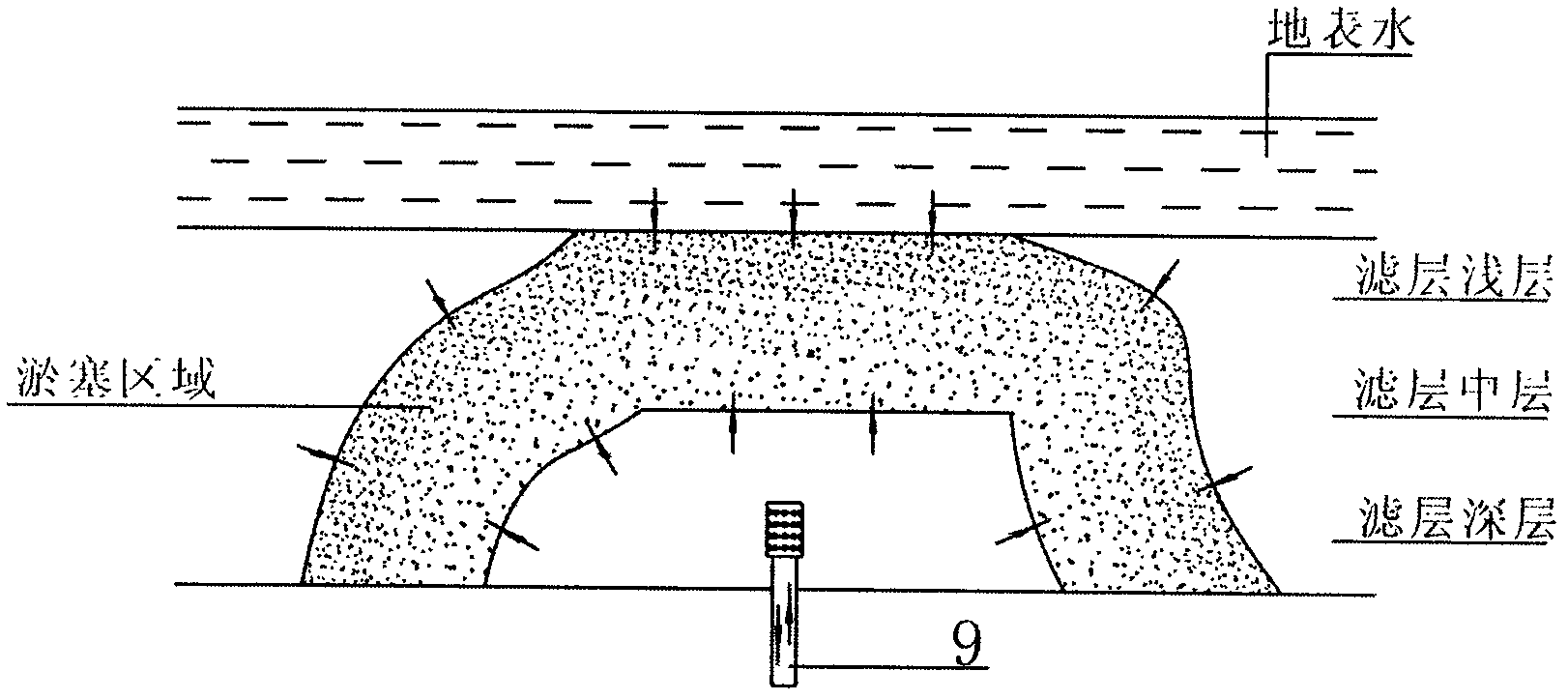

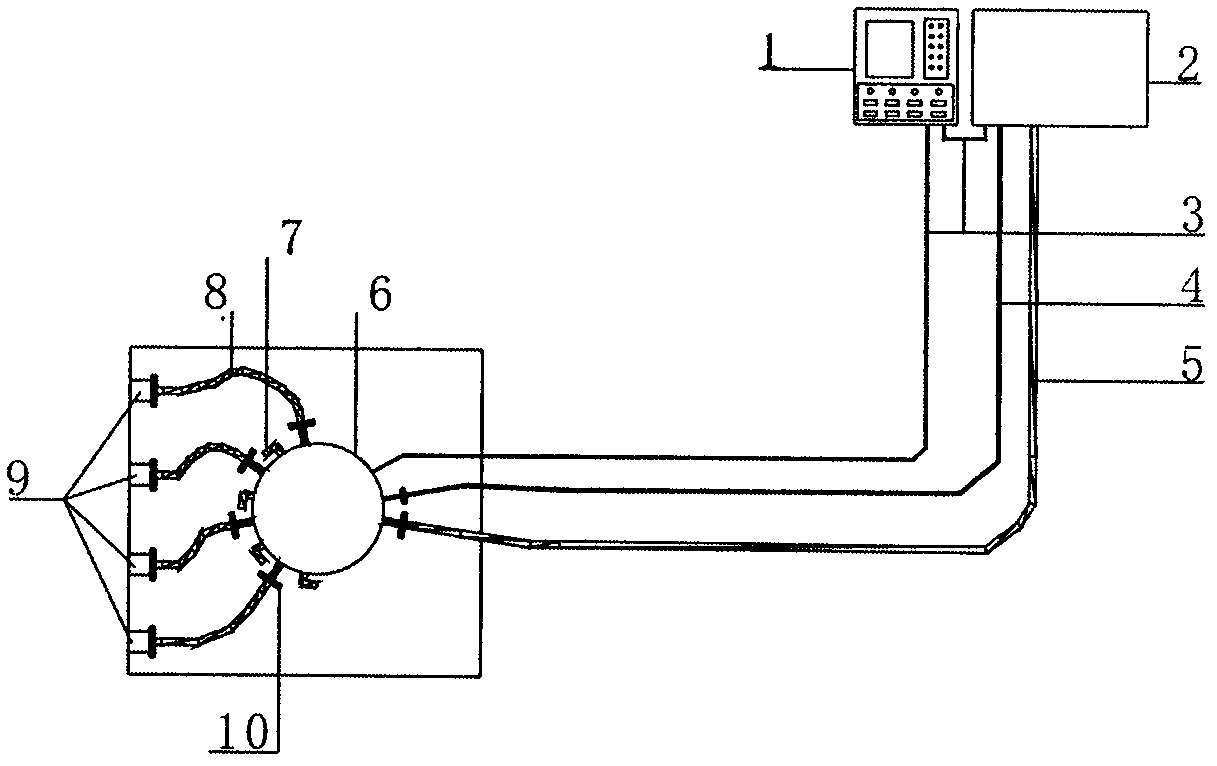

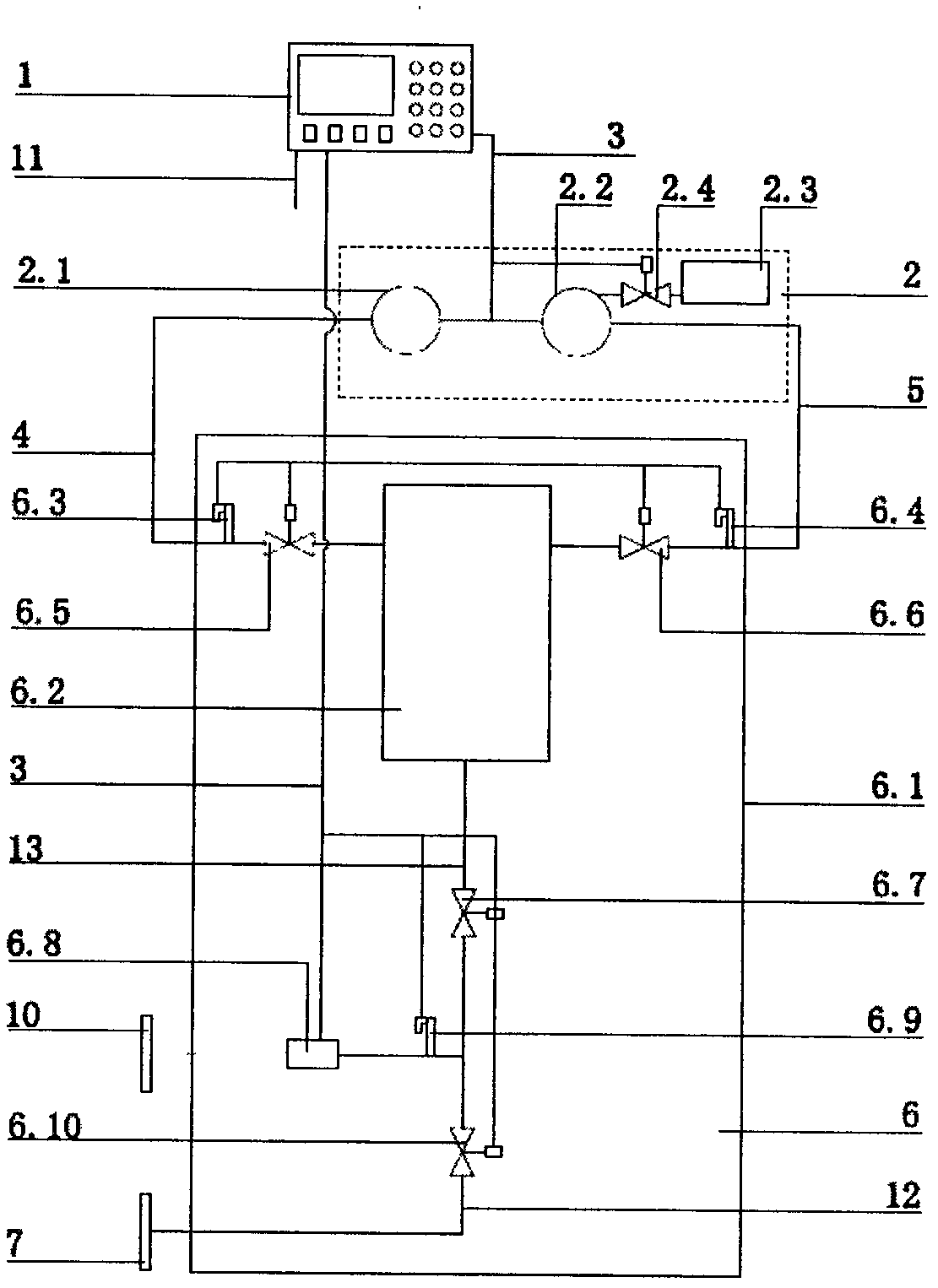

[0081] Such as figure 1 As shown, the method of backwashing the filter layer by diafiltration is used to remove the fouling in the filter layer. Close to the water intake pipe 9 is the deep layer of the filter layer, and the upper layer is the middle layer of the filter layer and the shallow layer of the filter layer; the backwash medium enters the filter layer through the water intake pipe 9, and the backwash medium is passed through the high-frequency oscillation method, the medium-frequency oscillation method, and the low-frequency oscillation method. The method and the pulse oscillation method act on the silted area of the filter layer, and the backwash medium reciprocates or pulses in the silted area of the filter layer, driving the silt and attachments to reciprocate or pulsate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com