Reaction kettle

The technology of a reaction kettle and a reaction chamber is applied in the field of reaction kettles for preparing solid granular materials by a wet method. Guaranteed, low-cost results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

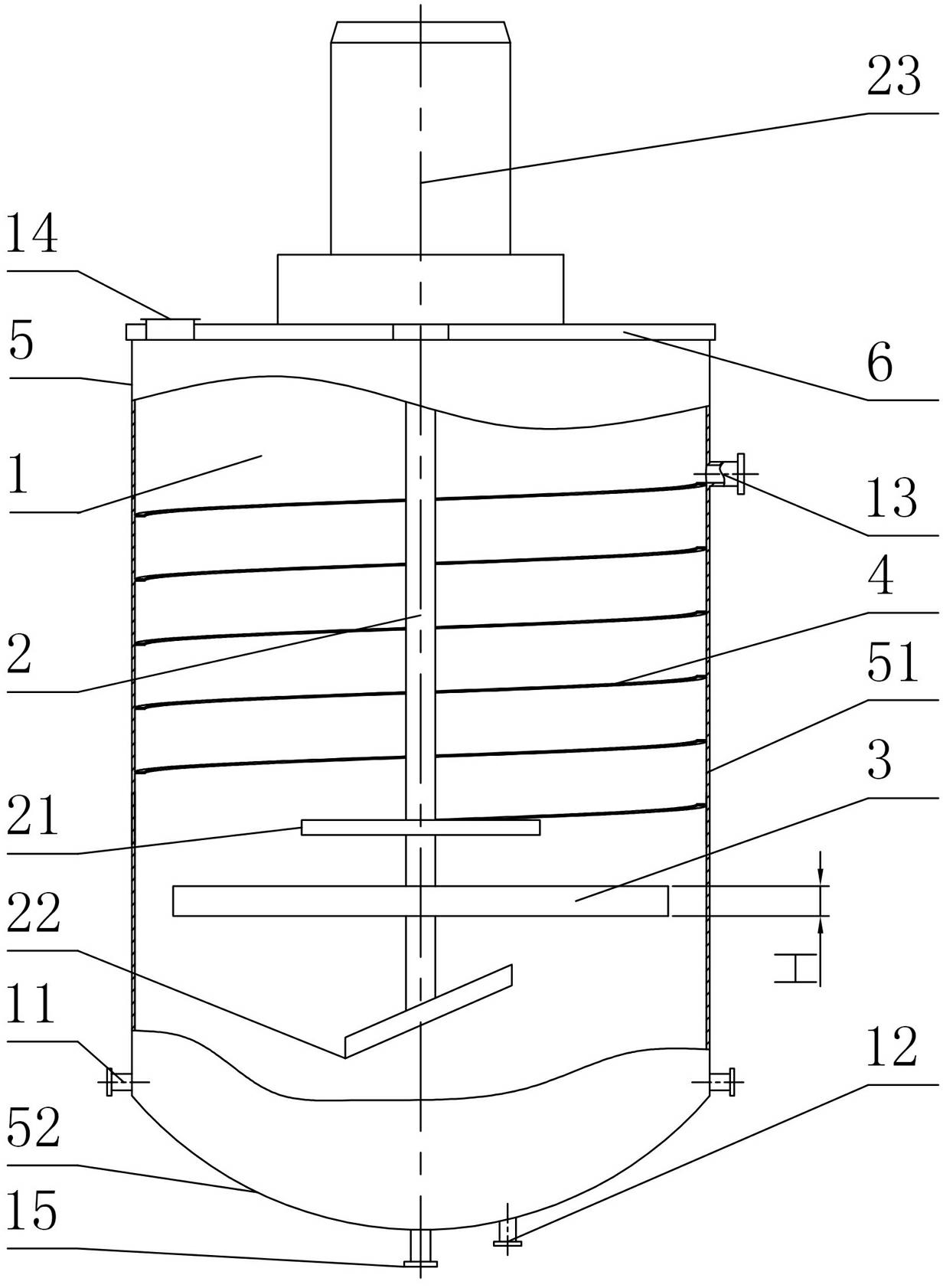

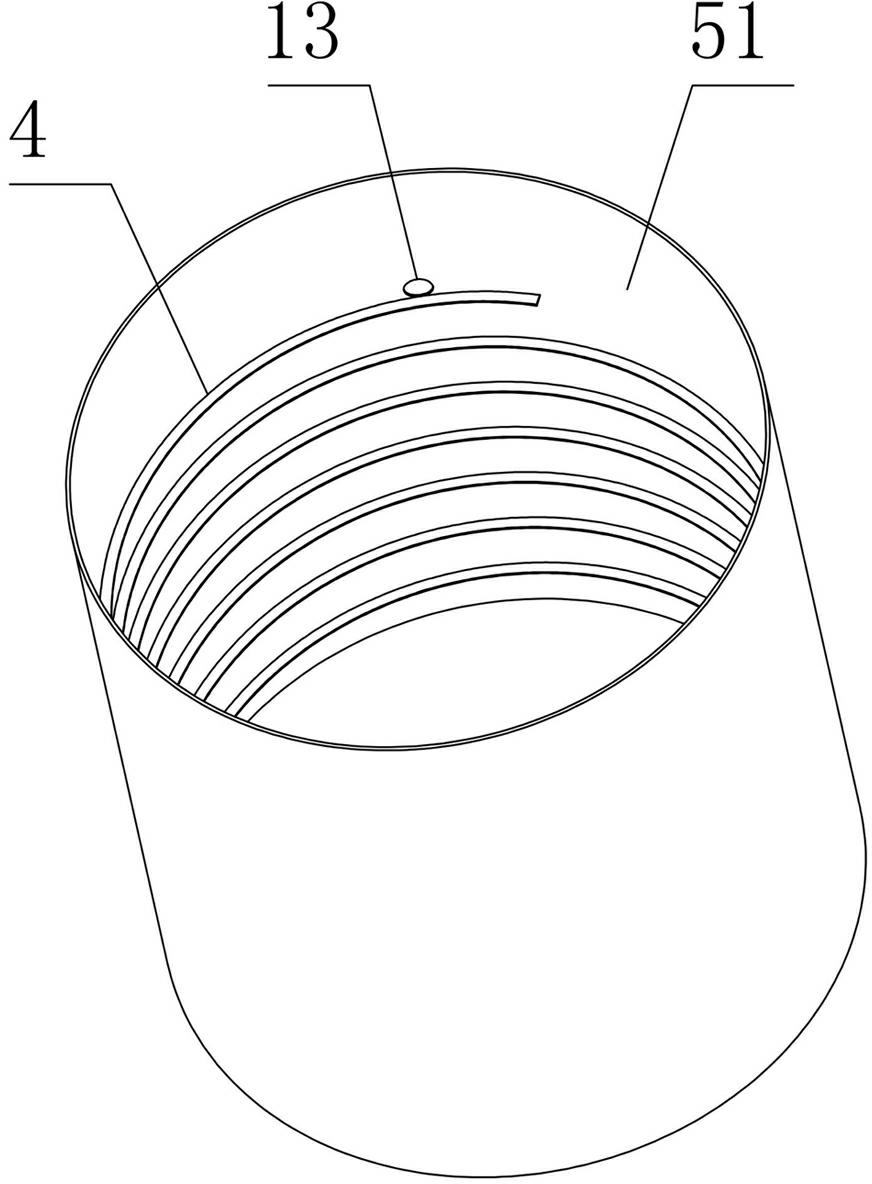

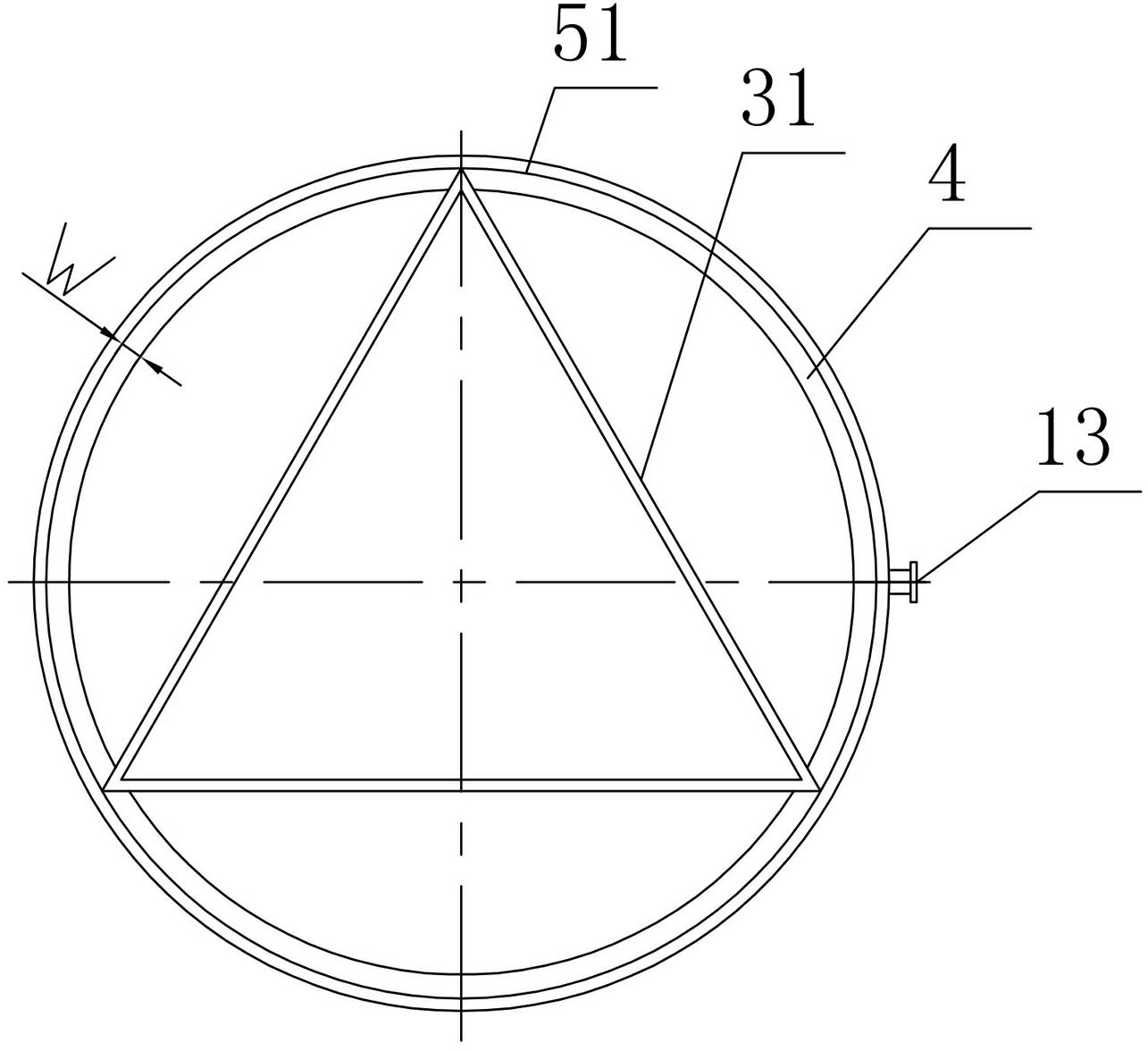

[0020] a kind of like Figure 1 ~ Figure 2 Shown reaction still of the present invention, this reaction still comprises the reaction chamber 1 that is made of still body 5 and still cover 6, and still body 5 comprises circumferential sidewall 51 and the still bottom 52 that links to each other with sidewall 51; The reaction A stirrer 2 is installed in the reaction chamber 1 of the still, and a power unit 23 connected to the stirrer 2 is installed on the still cover 6; two feeding ports 11 and a measuring port 12 are provided on the bottom 52 of the reaction still ( The position of the measuring port of the feed port can be interchanged arbitrarily), the center position of the bottom 52 of the kettle is provided with a bottom valve port 15, the upper part of the reaction kettle is provided with an overflow port 13, and the lid 6 of the kettle is also provided with a manhole 14. A horizontal baffle assembly 3 is provided near the stirring paddle of the agitator 2 , and a spiral ...

Embodiment 2

[0026] a kind of like Figure 1 ~ Figure 2 Shown reaction still of the present invention, this reaction still comprises the reaction chamber 1 that is made of still body 5 and still cover 6, and still body 5 comprises circumferential sidewall 51 and the still bottom 52 that links to each other with sidewall 51; The reaction A stirrer 2 is installed in the reaction chamber 1 of the still, and a power unit 23 connected to the stirrer 2 is installed on the still cover 6; two feeding ports 11 and a measuring port 12 are provided on the bottom 52 of the reaction still ( The position of the measuring port of the feed port can be interchanged arbitrarily), the center position of the bottom 52 of the kettle is provided with a bottom valve port 15, the upper part of the reaction kettle is provided with an overflow port 13, and the lid 6 of the kettle is also provided with a manhole 14. A horizontal baffle assembly 3 is provided near the stirring paddle of the agitator 2 , and a spiral ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com