Method for preparing cadmium hydroxide nanowires

A technology of cadmium hydroxide and nanowires, applied in chemical instruments and methods, nanotechnology, cadmium compounds, etc., can solve the problems of polluting the environment, increasing toxic heavy metal cadmium, affecting battery capacity, etc., and achieves good repeatability and excellent product appearance. Uniform, capacity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

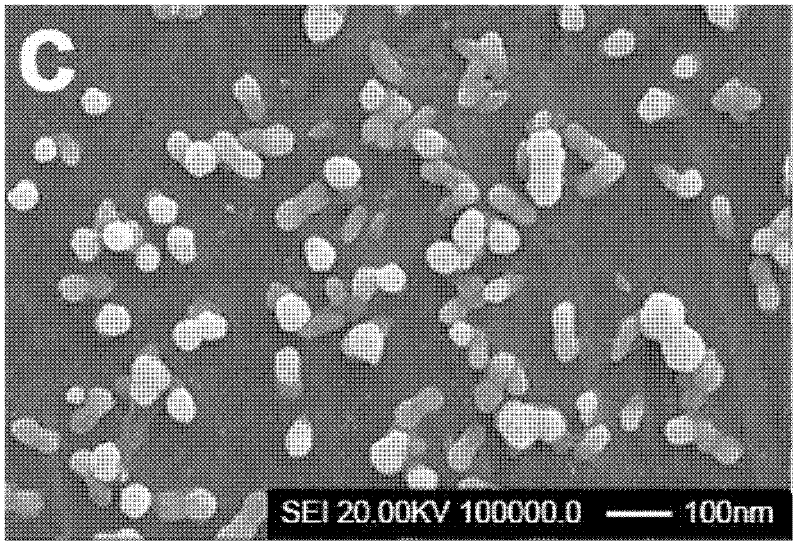

[0020] 1. Preparation of cadmium hydroxide nanowires:

[0021] Step 1: Take a 1×10cm rectangular pure copper sheet, and use acetone to ultrasonically clean the copper sheet;

[0022] The second step: 10mL of benzene and 50mL of 0.1mol / L cadmium nitrate solution are mixed in a 100ml beaker.

[0023] The third step: Slowly add 10 mL of 0.5 mol / L sodium hydroxide solution to the one-step solution.

[0024] Step 4: Put the beaker in a fume hood, react at room temperature for 48 hours, take out the precipitate, wash it with distilled water first, then with absolute ethanol, and dry it in the air to get the cadmium hydroxide nanowire .

Embodiment 1

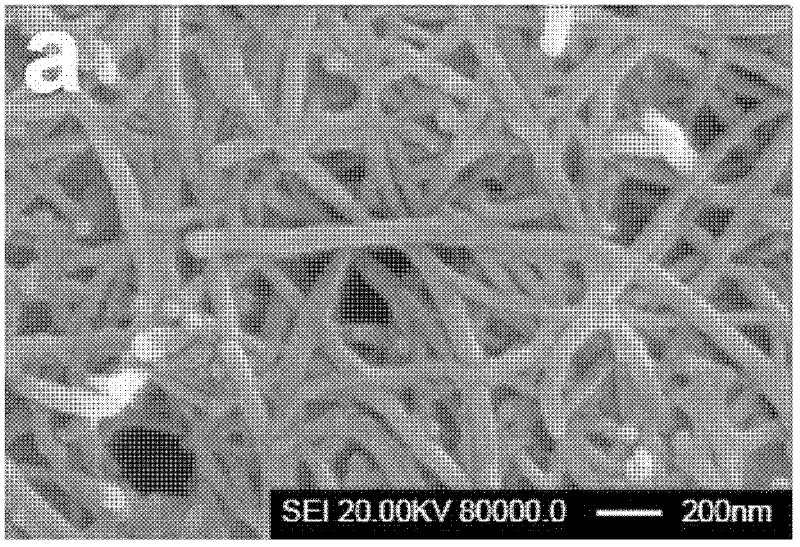

[0026] In this example, cadmium hydroxide nanowires were successfully prepared by the room temperature solution method.

[0027] Step 1: Take a 1×10cm rectangular pure copper sheet, and use acetone to ultrasonically clean the copper sheet;

[0028] The second step: 10mL of benzene and 50mL of 0.1mol / L cadmium nitrate solution are mixed in a 100ml beaker.

[0029] The third step: Slowly add 10 mL of 0.5 mol / L sodium hydroxide solution to the one-step solution.

[0030] Step 4: Put the beaker in a fume hood, react at room temperature for 48 hours, take out the precipitate, wash it with distilled water first, then with absolute ethanol, and dry it in the air to get the cadmium hydroxide nanowire .

Embodiment 2

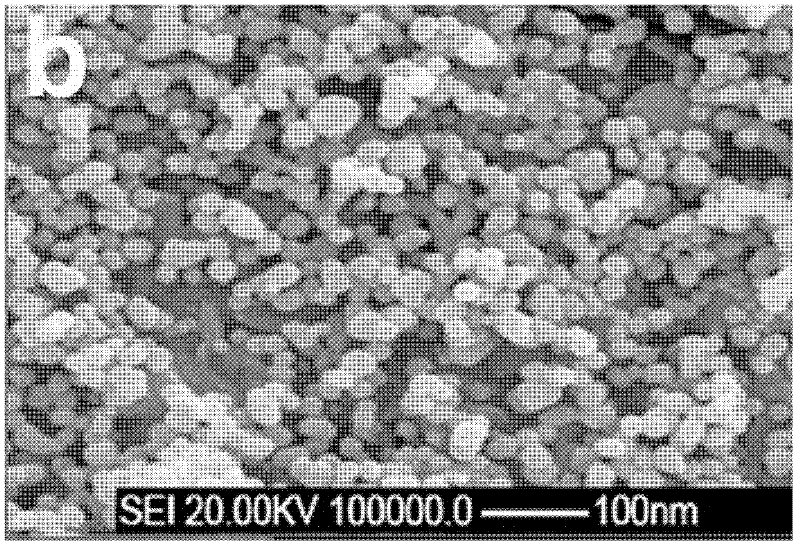

[0032] This embodiment is compared with embodiment one

[0033] Step 1: Take a 1×10cm rectangular pure copper sheet, and use acetone to ultrasonically clean the copper sheet;

[0034] The second step: 10mL of benzene and 50mL of 0.1mol / L cadmium nitrate solution are mixed in a 100ml beaker.

[0035] The third step: Slowly add 50 mL of 0.1 mol / L sodium hydroxide solution to the one-step solution.

[0036] Step 4: Put the beaker in a fume hood, react at room temperature for 48 hours, take out the precipitate, wash it with distilled water first, then with absolute ethanol, and dry it in the air to get cadmium hydroxide nanoparticles .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com