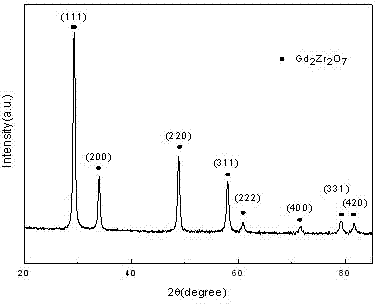

Method for preparing Gd2Zr2O7 nano-powder sol with sol-gel method

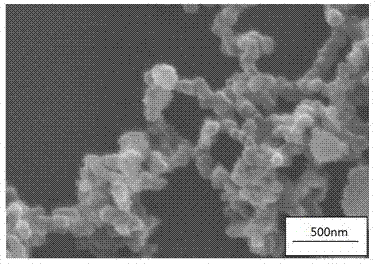

A sol-gel method, nano-powder technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of missing nano-powder materials, and achieve short preparation period, simple raw materials, and good dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

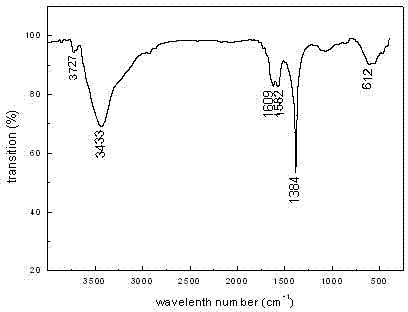

[0025] According to the preparation process, accurately weigh 0.529g, ZrOCl 2 ﹒ 8H 2 Dissolve O in 15ml of distilled water, add 5.5ml of ammonia water dropwise, stir well to obtain a white colloidal precipitate, filter the precipitate, and wash it with dedistilled water several times to remove Cl - , dissolve the precipitate in 30ml, 0.05mol / L dilute nitric acid, stir to obtain ZrO(NO 3 ) 2 solution. Add 0.529g, Gd 2 o 3 Dissolve in 30ml, 0.05mol / L dilute nitric acid solution to form Gd(NO 3 ) 3 solution, and with ZrO(NO 3 ) 2 The solution is mixed. Add 1.328g of citric acid to the mixture, stir to dissolve, add 5.37ml of ethylene glycol, adjust the pH of the system to 2 with concentrated ammonia water while stirring continuously, add 7ml of absolute ethanol, heat and evaporate in a water bath at 80°C 24h to form a transparent gel. The gel was dried in a drying oven at 120° C. to form a gray-brown fluffy and porous xerogel. The xerogel was ground and sieved and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com