Fiber-modified gypsum-based composite material

A composite material and fiber modification technology, which is applied in the field of fiber-modified gypsum-based composite materials, can solve the problems of no improvement in gypsum strength and toughness, general lifting effect, and complicated process, so as to achieve good social benefits, increase strength, and improve The effect of ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

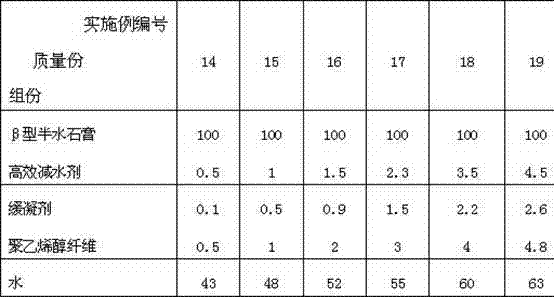

Examples

Embodiment 1

[0019] A fiber-modified gypsum-based composite material, recorded in parts by mass (for example: kilograms, the same below), firstly mix 100 parts of β-type hemihydrate phosphogypsum, 1.2 parts of polyvinyl alcohol fiber with a length of 9 mm, and 0.5 parts of high-efficiency reducing Add water agent and 0.1 part of retarder to the mixer and pre-stir for 60s, then add 46 parts of water and stir for 120s~180s, after stirring evenly, form a mold and vibrate to shape, and release the mold after it is condensed. The molded gypsum-based composites were cured under test conditions for 3 days. After testing, the 3-day flexural strength of the prepared composite material is 6.33MPa, and the compressive strength is 8.5MPa, which is 58.25% higher than that of the fiber-free material.

Embodiment 2

[0021] A fiber-modified gypsum-based composite material, recorded in parts by mass, first mix 100 parts of β-type hemihydrate phosphogypsum, 1 part of polyvinyl alcohol fiber with a length of 12 mm, 1 part of high-efficiency water reducer and 0.1 part of retarder Add to the mixer and pre-stir for 60s, then add 46 parts of water and stir for 120s to 180s, stir evenly, form a mold and vibrate to shape, and release the mold after it is condensed. The molded gypsum-based composites were cured under test conditions for 3 days. After testing, the 3-day flexural strength of the prepared composite material is 6.51MPa, and the compressive strength is 7.7MPa, which is 62.75% higher than that of the fiber-free material.

Embodiment 3

[0023] A fiber-modified gypsum-based composite material, recorded in parts by mass, first mix 100 parts of β-type hemihydrate phosphogypsum, 1.5 parts of polyvinyl alcohol fiber with a length of 15mm, 1 part of high-efficiency water reducer and 0.1 part of retarder Add to the mixer and pre-stir for 60s, then add 48 parts of water and stir for 120s to 180s, stir evenly, form a mold and vibrate to shape, and release the mold after condensation. The molded gypsum-based composites were cured under test conditions for 3 days. After testing, the 3-day flexural strength of the prepared composite material is 8.27MPa, and the compressive strength is 7.4MPa, which is 106.75% higher than that of the fiber-free material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com