Concrete water-retention curing agent and preparation method thereof

A water curing and concrete technology, which is applied in the field of concrete water retention and curing agents, can solve the problems of lack of water required for the hydration reaction of the concrete surface, damage the hydration structure, and affect the surface strength. High, the effect of preventing water evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below we will further illustrate the present invention in conjunction with specific embodiments.

[0021] The formula composition table of each embodiment of table 1.

[0022] components Example 1 Example 2 Example 3 Example 4 Example 5 Mixture% 7.50 8.20 9.55 10.80 13.50 rosin% 3.50 3.60 3.85 4.25 5.00 Surfactant% 6.50 7.50 7.60 8.70 10.00 pH adjuster% 0.50 0.70 1.00 1.25 1.5 water% 82 80 78 75 70

[0023] The preparation process is:

[0024] a. Weigh the mixture, rosin and surfactant according to the above formula, put them in a container, heat the temperature to 150°C~250°C, and then add the pH regulator;

[0025] b. After the PH value regulator is evenly added, stir at a constant temperature of 180°C for 10-30 minutes;

[0026] C. Add water at last, cool to room temperature and pack into a container to obtain the present invention for subsequent use.

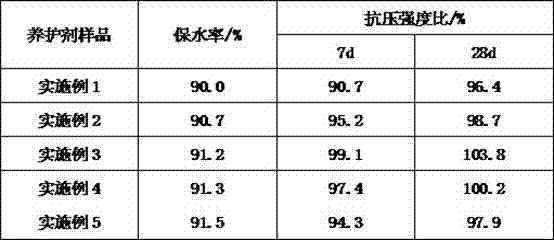

[0027] Table 2 is the test data table o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com