Phosphamide compound with flame retardance and preparation method and application thereof to epoxy resin

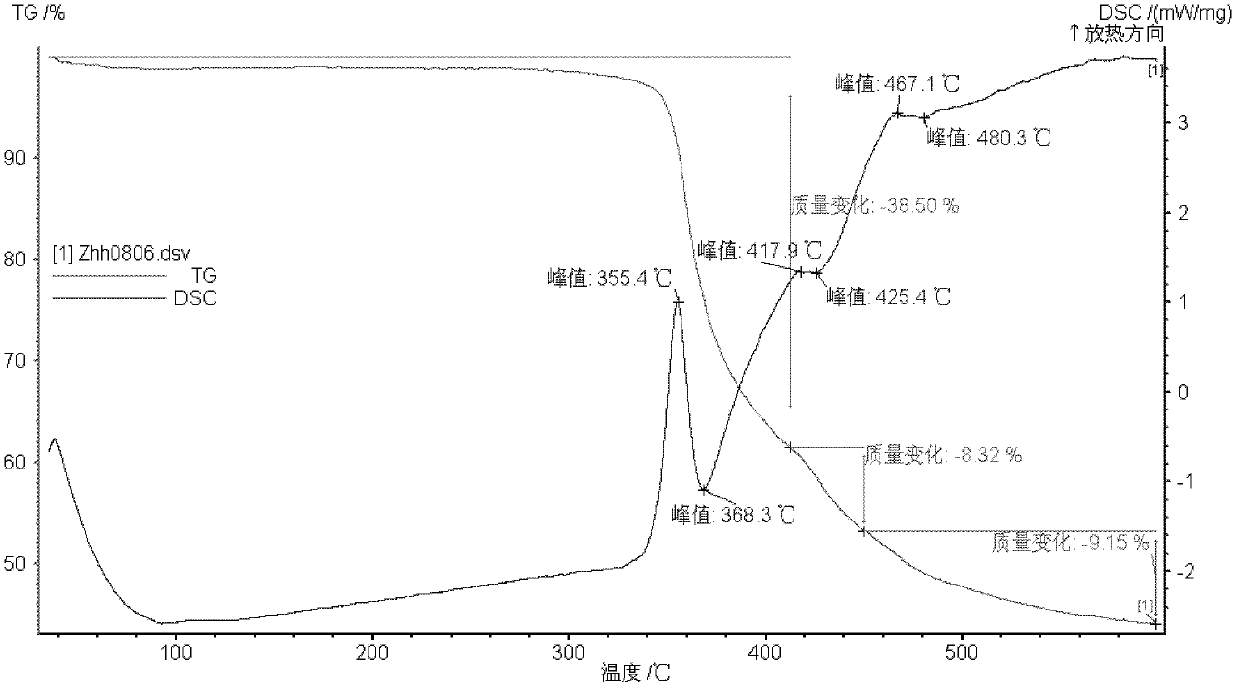

A compound, the technology of diphenylphosphoramide, applied in the field of flame retardants, can solve the problems of life and property safety threats, large heat release from smoke, fast burning speed, etc., and achieves easy operation, high yield and good thermal performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

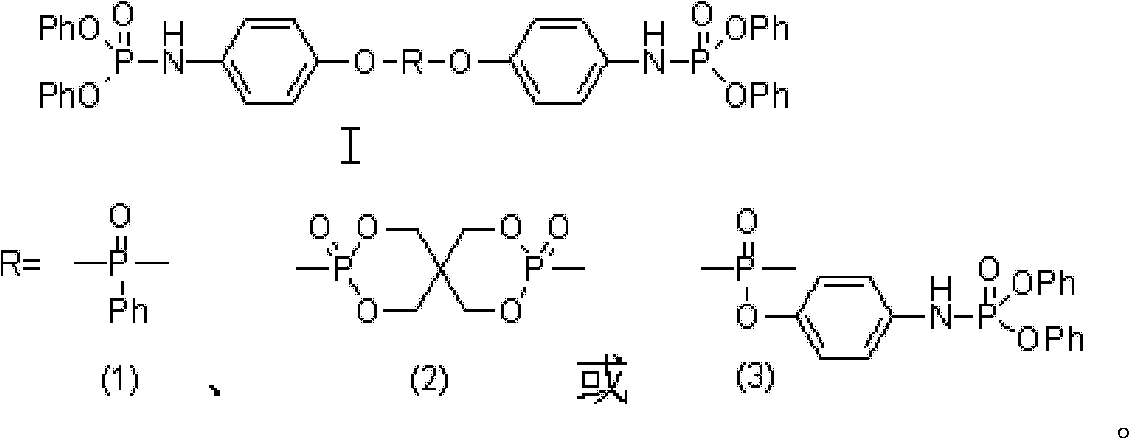

Method used

Image

Examples

Embodiment 1

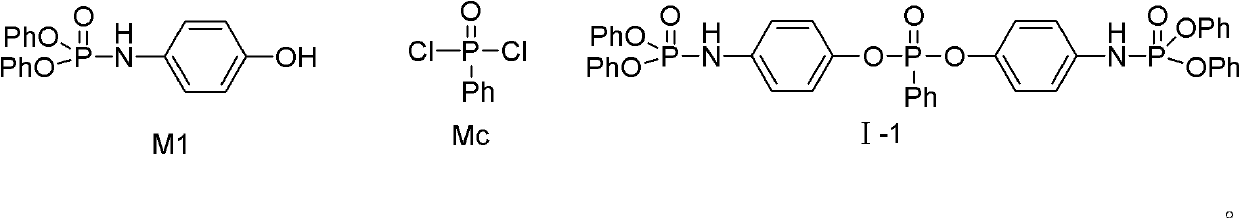

[0028] Preparation of intermediate M1:

[0029] Add 31.5g (0.3mol) of 4-aminophenol, 80.55g (0.3mol) of diphenyl chlorophosphate, catalytic amount (5%) of HOAt, and 200mL of toluene to a 500mL three-necked flask in sequence. 33 mL (0.36 mol) of tetrahydropyridine was added dropwise, and the addition was completed in 30 to 50 minutes. After reacting at 0-40°C for 8 hours, raise the temperature to 50-60°C and continue the reaction for 1-2 hours. After stopping the reaction, filter with suction, wash with water, and recrystallize with acetone:water=2:1 (V / V) to obtain 80.0 g of gray solid, the yield 79%, melting point 184-186°C.

Embodiment 2

[0031] Preparation of Compound I-1

[0032] In a 100mL three-neck flask equipped with a thermometer, a constant pressure dropping funnel and a reflux condenser, add 40mmol of the intermediate M140mmol, 0.2g of DMAP, 80mmol of pyridine, and 30mL of tetrahydrofuran, stir in an ice bath, control the temperature at -10 to 5°C, and add dropwise 10mL tetrahydrofuran solution dissolved with 20mmol of phenylphosphoryl dichloride, after adding, react at 5°C for 5h, heat up and reflux, stop the reaction after 1h, let stand and cool overnight, a white solid precipitates, filter with suction, DMF:H 2 O=4:1 (V / V) recrystallized to give a white solid with a yield of 87% and a melting point of 173-175°C.

[0033] 1 H NMR (600MHz DMSO-d 6 )δ(ppm): 7.11~7.14(t, 8H, Ph-H), 7.19~7.22(m, 12H, Ph-H), 7.37~7.40(t, 8H, Ph-H), 7.59~7.61(t , 2H, Ph-H), 7.71(s, 1H, Ph-H), 7.88~7.91(s, 2H, Ph-H), 8.14~8.86~8.88(d, 2H, N-H); 31 P NMR (400MHz) δ (ppm): -7.04 (s, O P (O)N), 12.15 (s, O P (O)C);IR(KBr...

Embodiment 3

[0035] Preparation of Compound I-2

[0036] In a 100mL three-necked flask, add intermediate M140mmol, NHPt 0.15g, spirophosphoryl chloride (Md) 30mmol, 1,2-dichloroethane 50mL, add triethylamine 80mmol dropwise at -15~10°C, and complete the addition , kept at 20-40°C for 3h, then raised the temperature to reflux, kept at reflux for 10h, stopped the reaction, let it stand for cooling, and then went through silica gel column chromatography to obtain a white solid with a yield of 65% and a melting point of 102-105°C.

[0037] 1 H NMR (600MHz CDCl 3 -d) δ (ppm): 4.14 ~ 4.20 (m, 2H, CH 2 O ), 4.25~4.28(m, 2H, CH 2O ), 4.51~4.53(t, 2H, CH 2 O ), 4.79~4.84(m, 2H, CH 2 O ), 6.74~6.75(d, 2H, N-H), 7.10~7.18(m, 20H, Ph-H), 7.27~7.30(m, 8H, Ph-H); 31 P NMR (400MHz) δ (ppm): -7.10 (s, O P (O)N), -13.54 (s, O P (O)O);IR(KBr)υ(cm -1 ): 3443(N-H), 3133(Ph-H), 2970(CCH 2 -H), 1638, 1570, 1509 (Ph-C), 1458 (CH 2 -H), 1262(P=O), 1139(P-N), 1122, 1070((P)-O-C), 995, 954(P(O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com