Degrading method for recovering polyurethane

A polyurethane and polycarbonate technology, which is applied in the field of recycled polyurethane degradation, can solve the problems of reduced reaction controllability and poor mechanical properties of polyurethane, so as to reduce the risk of secondary environmental pollution, better comprehensive mechanical properties, and shorten the The effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

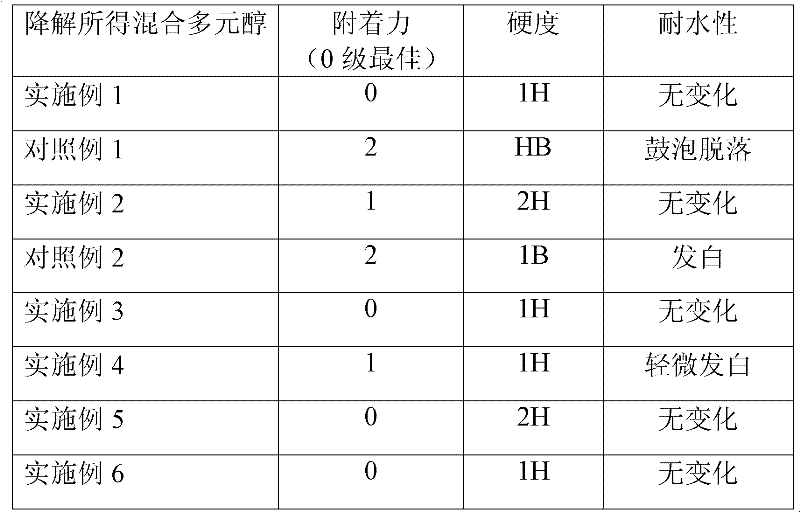

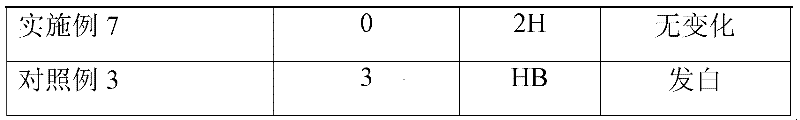

Examples

Embodiment 1

[0068] Add 50g of polycarbonate diol CD205 (Dalu) into a 500ml three-necked bottle with a stirrer, heat up to 220°C, start stirring, add 0.2g of potassium acetate and 0.5g of strontium carbonate, and add 0.5 % hindered phenol antioxidant, add 150g recycled polyurethane debris gradually, add 30min, after the polyurethane debris is completely dissolved, add 15g of water, continue to keep warm and stir for 1hr, when the stirring state drops to below 80°C, add 0.5g red aluminum solution was cooled to room temperature, discharged, and measured various indexes. The degradation product has a hydroxyl value of 94.2mgKOH / g, an amine value of 3.4mgKOH / g, an acid value of 0.8mgKOH / g, a Gardner chromaticity of 11, a viscosity of 8900cPs, a number average molecular weight of 6700, and a characteristic infrared absorption peak intensity ratio of urethane bonds and urea bonds of 7.3 : 1.

Embodiment 2

[0070] Add 100g polycarbonate diol CD220 (Dalu) into a 500ml three-necked bottle with a stirrer, heat up to 210°C, start stirring, add 0.2g sodium acetate and 0.4g strontium carbonate, add 0.5 % hindered phenol antioxidant, add 50g recycled polyurethane scraps gradually, add 20min, after the polyurethane scraps are completely dissolved, add 5g of water, continue to keep warm and stir for 4hrs, when the stirring state drops to below 50°C, add 0.5g of sodium borohydride solution was cooled to room temperature, discharged, and various indexes were measured. The degradation product has a hydroxyl value of 54.3mgKOH / g, an amine value of 2.2mgKOH / g, an acid value of 0.5mgKOH / g, a Gardner chromaticity of 13, a viscosity of 6560cPs, a number average molecular weight of 5300, and a characteristic infrared absorption peak intensity ratio of urethane bonds and urea bonds of 7.8 : 1.

Embodiment 3

[0072] Add 100g of polycarbonate diol CD210 (Dalu) into a 500ml three-necked bottle with a stirrer, heat up to 190°C, start stirring, add 0.2g of sodium acetate and 0.5g of strontium carbonate, and add 0.5 % hindered phenol antioxidant, add 100g recycled polyurethane debris gradually, add 30min, after the polyurethane debris is completely dissolved, add 10g of water, continue to keep warm and stir for 4hr, when the stirring state drops to below 50°C, add 0.5g of sodium borohydride solution was cooled to room temperature, discharged, and various indexes were measured. The degradation product has a hydroxyl value of 72.5mgKOH / g, an amine value of 3.6mgKOH / g, an acid value of 1.1mgKOH / g, a Gardner chromaticity of 11, a viscosity of 7400cPs, a number average molecular weight of 6100, and a characteristic infrared absorption peak intensity ratio of urethane bonds and urea bonds of 7.9 : 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| amine value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com