Solid polyferric sulfate flocculant and preparation method thereof

A technology of solid polymerization and ferric sulfate, which is applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, water/sludge/sewage treatment, etc. It can solve the problem of poor hydrophobic performance, limited adsorption performance and volume of polymerized iron salts. and low density to achieve the effect of increasing light stability, enhancing hydrophobic effect, and preventing flocculation failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

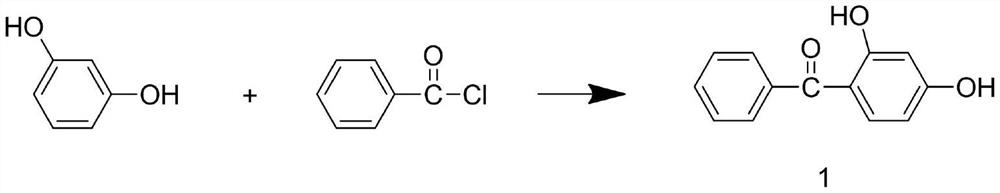

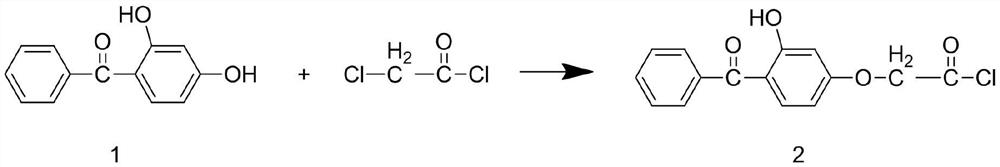

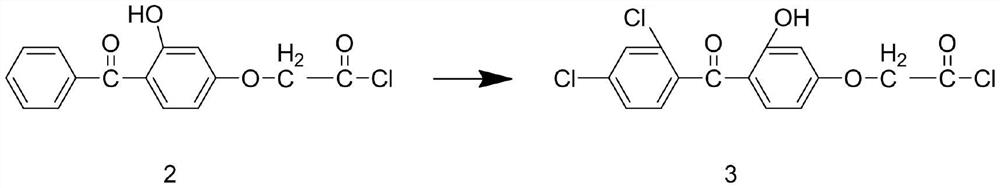

[0047]The modified monomer is made by the following steps:

[0048]Step S1, add 4 g of anhydrous aluminum chloride, 25 ml of amphiphenylphenol, add 7 ml of benzoyl chloride, temperature rise to 100 ° C, after cooling to room temperature, after cooling to room temperature, incubation to room temperature, incubation to room temperature, after cooling to room temperature, incubation to 100 ° C, after cooling to room temperature After the precipitate is dissolved, the organic layer is separated, and the natural layer is washed with a mass fraction of 5% NaOH solution and deionized water, collect the organic layer, the crude product, and the crude product is evaporated under reduced pressure. Phenol and deionized water. After cooling, the solid, filtrate, water washing, ethanol recrystallization, dry, and the intermediate 1;

[0049]Step S2, 0.1 mol of triethylamine, 40 ml of tetrahydrofuran, stirred and dissolved to a mixed solution mixed under an ice bath, and a mixed solution mixed with mas...

Embodiment 2

[0055]The modified monomer is made by the following steps:

[0056]Step S1, 5 g of an aluminum chloride, 30 ml of amphiphenylphenol is added to the three flask, and 10 ml of benzoyl chloride is added dropwise to 100 ° C, and the reaction is 8 h, after cooling to room temperature, add 15 ml of deionized water to stir After the precipitate is dissolved, the organic layer is separated, and the natural layer is washed with a mass fraction of 5% NaOH solution and deionized water, collect the organic layer, the crude product, and the crude product is evaporated under reduced pressure. Phenol and deionized water. After cooling, the solid, filtrate, water washing, ethanol recrystallization, dry, and the intermediate 1;

[0057]Step S2, 0.15 mol of triethylamine, 50 ml of tetrahydrofuran, stirred and dissolved, and tetrahydrofuran is added dropwise under an ice bath, and the mixed solution mixed with mass ratio 1: 2 after stirring. The mixture was stirred, and the bath was added dropwise under the...

Embodiment 3

[0063]Solid polymeric sulfate flt coagulant, including materials such as weight:

[0064]FE2(SO4)3XH2O 20 parts, 8 parts of water glass, 10 parts of KH-5602, acrylamide, 8 modified monomers, 1 chain chain agent DA1, 0.5 parts of formaldehyde, sodium hydrogen sulfate, SPAN-201, ammonium sulfate 3 copies;

[0065]The solid polymeric sulfate flocculant is made of steps:

[0066]Step A1, will Fe2(SO4)3XH2O Among deionized water, heating is heated at 65 ° C to dissolve, sodium hydroxide, 30 minutes of 30 min, resulting in mixed liquid A, where deionized water is used in Fe2(SO4)3XH2O 3 times the mass of O, the amount of sodium hydroxide is Fe2(SO4)3XH2O 0.5 times the quality;

[0067]Step A2, the water glass was added to deionized water, pH to 6 with 0.1 g / ml of hydrochloride, stirred for 2 h, and stirred for 30 min, mixed with mixed liquid a stirred for 2 h, add acrylamide, Example 1 After the modified monomer, the mixture is stirred, the pH is adjusted with a mass fraction of 30% ammonia water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com