Sub-high temperature vulcanized solid sound-transmitting rubber and preparation method thereof

A sound-transmitting rubber and sub-high temperature technology, which is applied in the field of rubber and its preparation, can solve the problems of low production efficiency, difficult operation, water resistance and sealing, etc., and achieve the effects of lowering the critical temperature, increasing the vulcanization speed, and prolonging the scorch time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

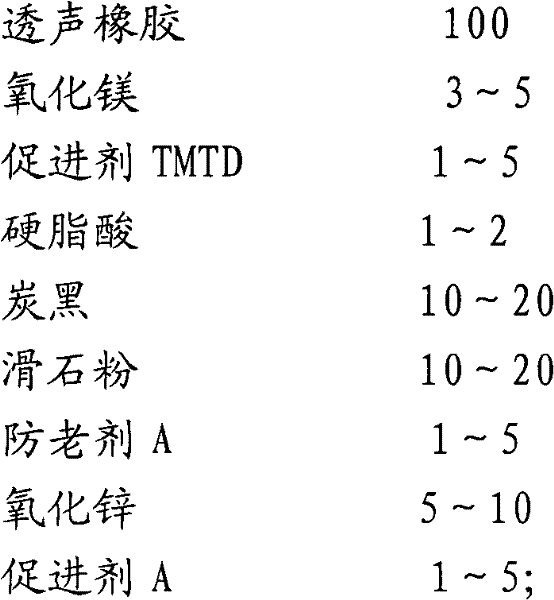

[0027] Embodiment 1: A sub-high temperature vulcanized solid sound-permeable rubber, characterized in that: the parts by weight of each raw material are composed of:

[0028]

[0029] Plasticize the above chloroprene rubber components with an open mill, and control the roller temperature within 55-65°C; until the Mooney viscosity ML(1+4)100 is 30-40;

[0030] Mix the above plasticized rubber with an open mill: control the temperature of the rollers within 55-65°C, and control the temperature of the glue within 70-80°C; add the magnesium oxide and accelerator TMTD components in the ingredients in sequence, and then add Stearic acid, carbon black, talcum powder, anti-aging agent A component, and finally add zinc oxide and accelerator A; after thin pass, the next sheet is made into an unvulcanized solid sound-permeable rubber sheet; the vulcanization curve is made by sampling, and the vulcanization condition is 100℃×120min, T10 is 10-20 minutes, T90 is 45-55 minutes;

[0031]...

Embodiment 2

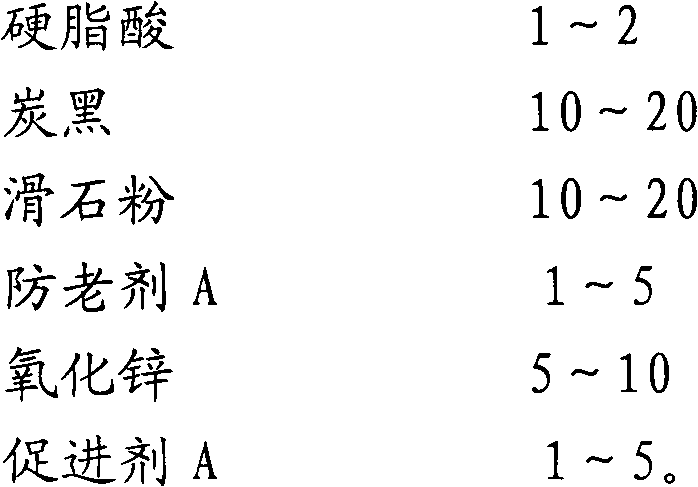

[0036] Embodiment 2: A sub-high temperature vulcanized solid sound-permeable rubber, characterized in that: the parts by weight of each raw material are composed of:

[0037]

[0038] Preparation:

[0039] According to the preparation method of Example 1, a solid sound-permeable rubber is made, and after testing, its performance is:

[0040] Tensile strength (MPa)

[0041] The solid sound-permeable rubber is suitable for cladding sound-permeable materials for ships and other water-tight sound-permeable materials bonded with metal.

Embodiment 3

[0042] Embodiment 3: A sub-high temperature vulcanized solid sound-permeable rubber, characterized in that: the parts by weight of each raw material are composed of:

[0043]

[0044] According to the preparation method of Example 1, a solid sound-permeable rubber is made, and after testing, its performance is:

[0045] Tensile strength (MPa)

[0046] The solid sound-permeable rubber is suitable for cladding sound-permeable materials for ships and other water-tight sound-permeable materials bonded with metal.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Permanent deformation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com