Coating for children and preparation method thereof

A paint, children's technology, applied in anti-fouling/underwater paints, coatings, paints containing biocides, etc., can solve the problems of poor scrub resistance, unsuitable for children, powder drop, etc., to reduce noise, suppress The effect of bacteria and mold growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The preparation method of children's paint provided by the invention comprises the following steps:

[0042] Pre-mixing: Add dispersant, wetting agent, 0.1-0.2 parts by weight of defoamer and cellulose thickener to 17-20 parts by weight of water, and mix thoroughly to form a gel-like substance to facilitate the dispersion of pigments and fillers. The stirring speed can be controlled at 300-500RPM;

[0043]Grinding and dispersing: Add titanium dioxide, diatomaceous earth, and heavy calcium powder to the mixture, and control the speed at 2000-3000RPM for beating and grinding for 20-25 minutes. Check the beating and grinding until the fineness is ≤60um. Under the high shear rate of high-speed stirring, it is dispersed into primary particles, and a stable state of dispersion is obtained under the action of the dispersion aid system;

[0044] Add emulsion: After high-speed grinding and dispersing, add 3-5 parts by weight of water, preservatives, and anti-fungal agents to th...

Embodiment 1

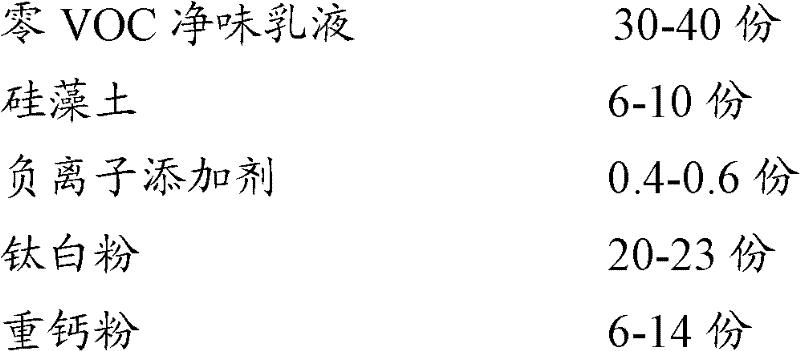

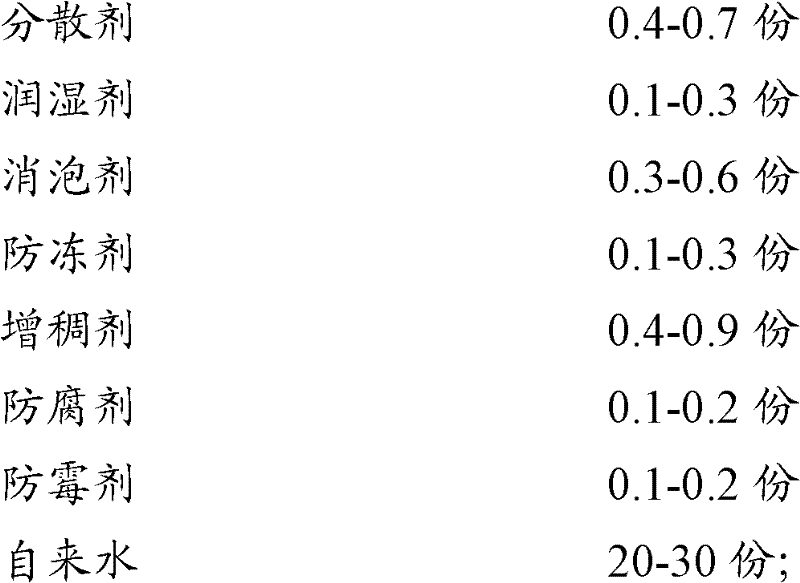

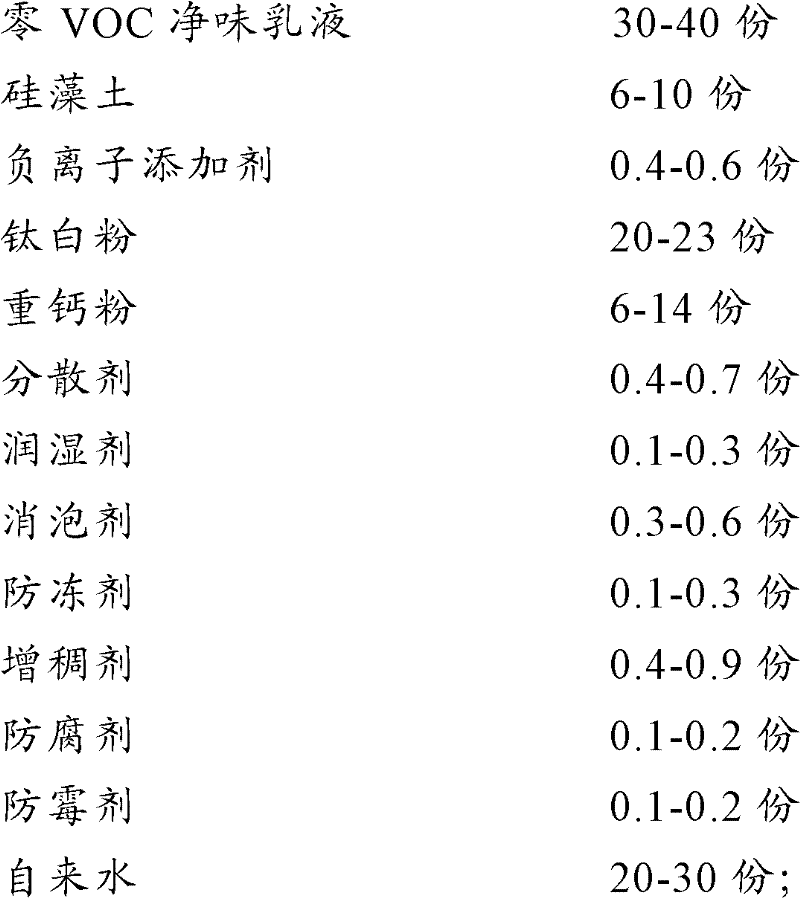

[0047] Ingredients include:

[0048] Functional material: 33 parts of Celvolit CP 1788 zero-VOC deodorant lotion,

[0049] The model produced by American World Minerals is 7 parts of diatomaceous earth of celite 495,

[0050] The model produced by Beijing Langnuo Environmental Protection Technology Co., Ltd. is HB-TL negative ion paint additive 0.5 parts,

[0051] Pigments and fillers: 22 parts of titanium dioxide with the model R-706 produced by DuPont in the United States, 8 parts of heavy calcium powder with the model CC-1000 produced by Guangzhou Fujian Material Company,

[0052] Auxiliary agent: 0.5 part of dispersant of model LOPON 800 produced by German Baker Gilini Company,

[0053] The model produced by U.S. Air Chemical Products Company is 0.1 part of wetting agent of Carbowet 13-40,

[0054] 0.3 parts of defoamer of LOPON E81 is the model produced by German Baker Gilini Company,

[0055] French Rhodia company produces 0.15 parts of antifreeze agent of model FT-1...

Embodiment 2

[0065] Ingredients include:

[0066] Functional material: 40 parts of Celvolit CP 1788 zero-VOC deodorizing emulsion,

[0067] Celite 495 diatomaceous earth 8 parts,

[0068] 0.4 parts of HB-TL negative ion paint additive,

[0069] Pigment and filler: 21 parts of R-706 titanium dioxide,

[0070] CC-1000 heavy calcium powder 10 parts,

[0071] Auxiliary: 0.6 parts of LOPON 800 dispersant,

[0072] Carbowet 13-40 wetting agent 0.2 parts,

[0073] 0.6 parts of LOPON E81 defoamer,

[0074] 0.1 parts of FT-100 antifreeze,

[0075] 0.2 parts of QP30000H thickener,

[0076] RHEOLATE425 thickener 0.4 parts,

[0077] 0.2 parts of BT NV2 preservative,

[0078] polyphase PW40 antifungal agent 0.2 parts,

[0079] 30 parts of tap water.

[0080] Add 23 parts of water into the dispersing tank, add the above dispersant, wetting agent, 0.2 part of defoamer and cellulose thickener respectively, and mix thoroughly to form a gel-like substance. The mixing speed is controlled at 450RPM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com