Magnesium alloy surface pretreatment method

A surface pretreatment, magnesium alloy technology, applied in metal material coating process, fusion spraying, coating, etc., can solve the problem that the bonding performance needs to be further improved, to prevent falling off, increase roughness, and eliminate microcracks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (a) Flattening treatment of the end face of magnesium alloy round ingot. The end face of the magnesium alloy round ingot is machined, and the roughness Ra is required to be 3.2.

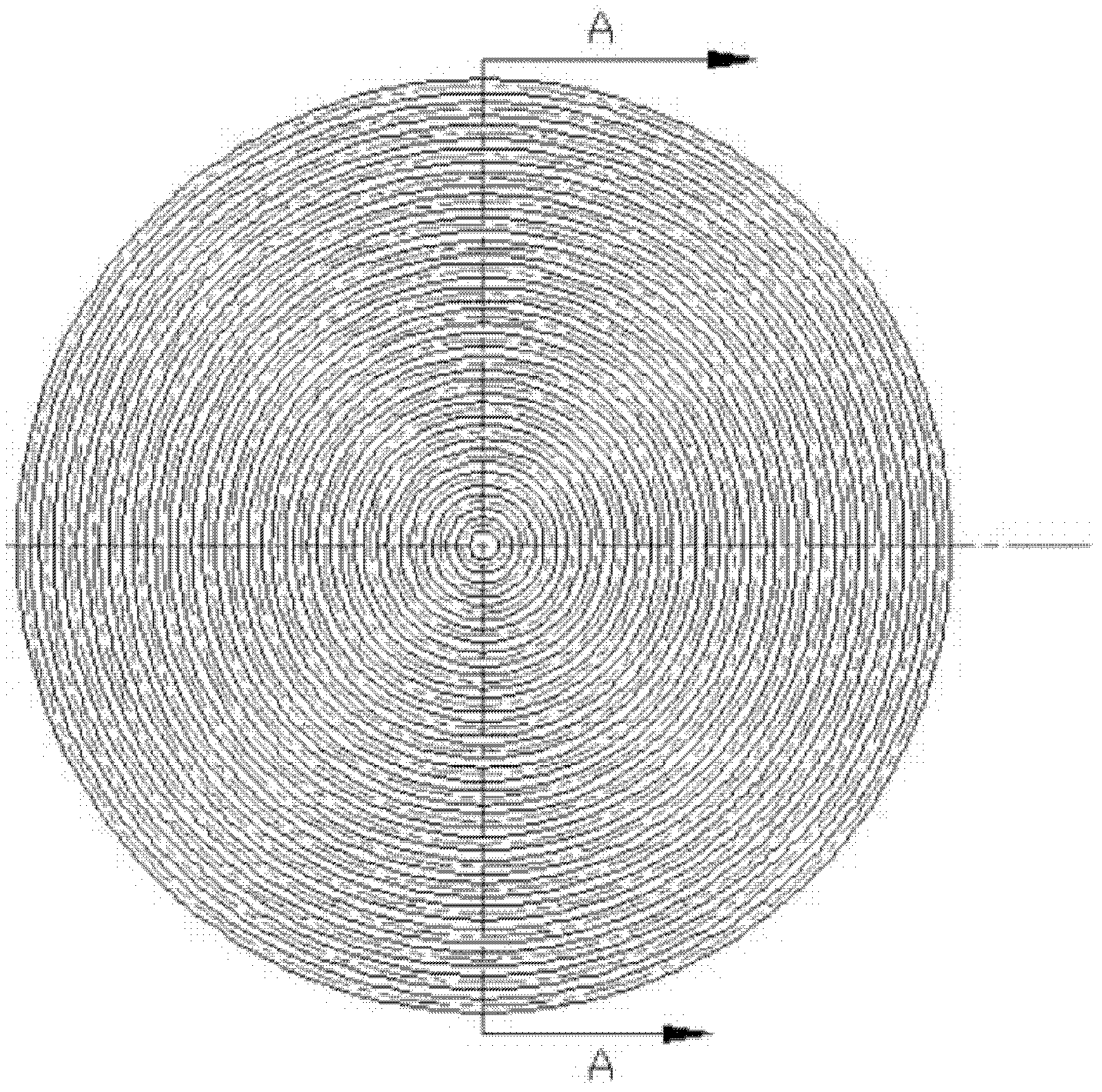

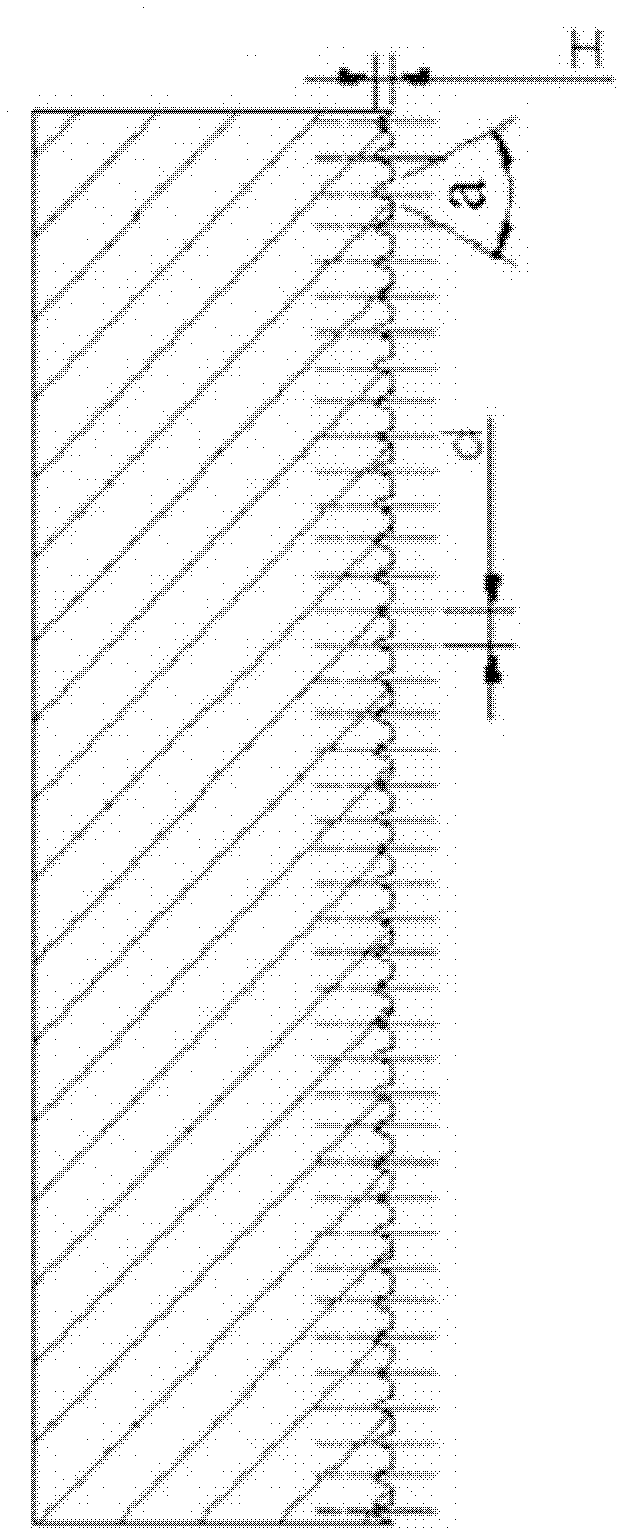

[0023] (b) Wipe off the grease on the end surface of the magnesium alloy round ingot treated in (a) with acetone, use a V-shaped turning tool with a of 60° to process the concentric V-shaped groove on the end surface, and grind the sharp corners of the turning tools to avoid sharp corner processing . The groove depth H is 1 mm, and the distance d between centers of the concentric V-shaped grooves is 1.95 mm. See figure 1 and figure 2 as shown,

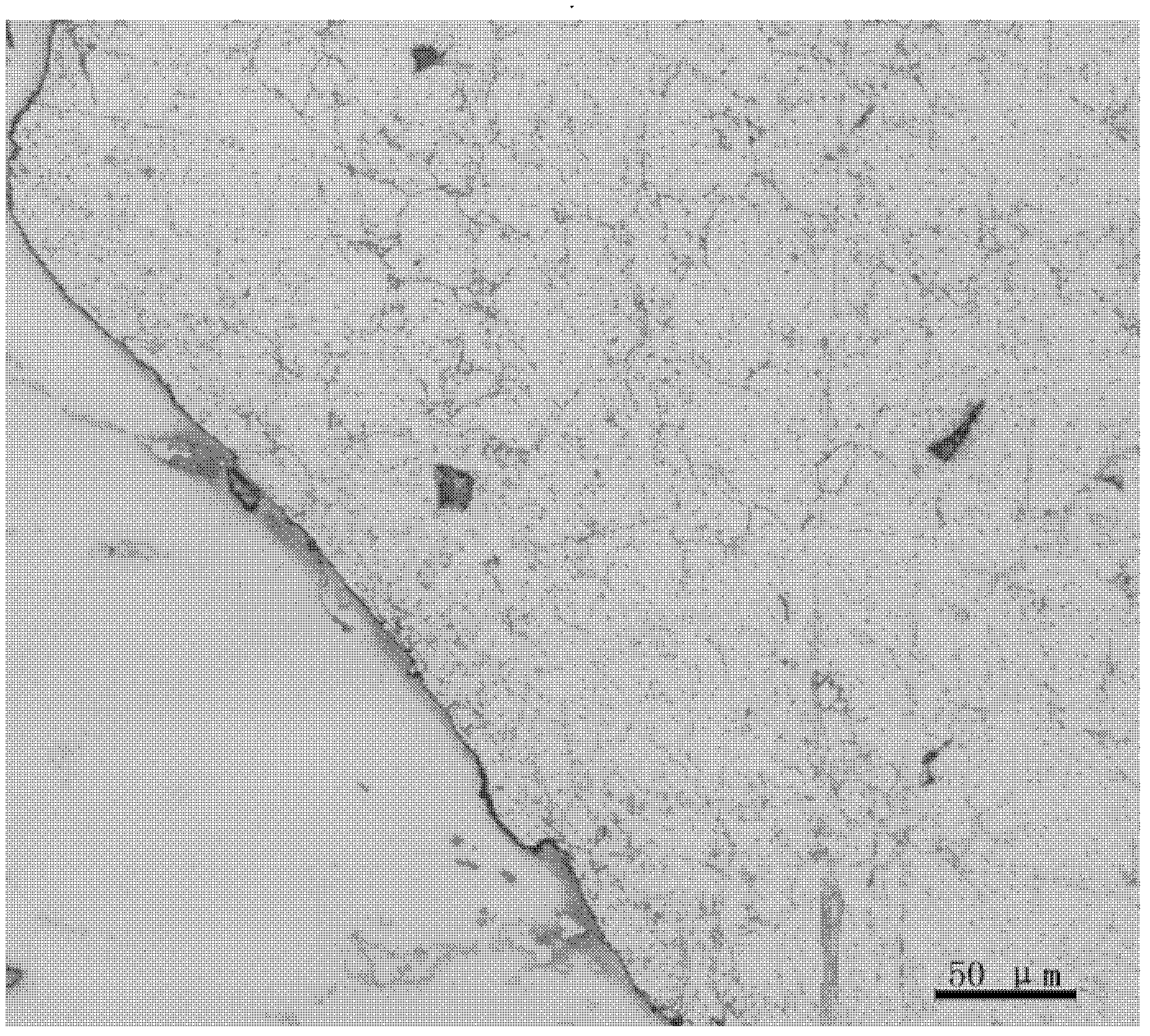

[0024] (c) Carry out magnesium swarf removal to the V-shaped groove machined by step (b), and carry out surface blasting treatment immediately after wiping clean with acetone. Quartz sand is used as the abrasive, the particle size is 20 mesh, the distance from the sandblasting nozzle to the blasting surface is 100mm, and the axis of the spray gun...

Embodiment 2

[0030] (a) Flattening treatment of the end face of magnesium alloy round ingot. The end face of the magnesium alloy round ingot is machined, and the roughness Ra is required to be 6.4.

[0031] (a) Wipe off the grease on the end surface of the magnesium alloy round ingot treated in (a) with acetone, use a 55° V-shaped turning tool to process the concentric V-shaped groove on the end surface, and round the sharp corners of the turning tool to avoid sharp corner processing. The groove depth is 1.5mm, and the center distance of concentric V-shaped grooves is 2.53mm.

[0032] (b) Carry out magnesium swarf removal to the V-shaped groove machined by step (b), and carry out surface blasting treatment immediately after wiping clean with acetone. Quartz sand is used as the abrasive, the particle size is 20 mesh, the distance from the sandblasting nozzle to the blasting surface is 150mm, and the axis of the spray gun forms an angle of 75° with the surface.

[0033] (c) After step (c),...

Embodiment 3

[0038] (a) Flattening treatment of the end face of magnesium alloy round ingot. The end face of the magnesium alloy round ingot is machined, and the roughness Ra is required to be 3.2.

[0039] (b) Clean the grease on the end surface of the magnesium alloy round ingot treated in (a) with acetone, use a 65° V-shaped turning tool to process the concentric V-shaped groove on the end surface, and round the sharp corners of the turning tool to avoid sharp corner processing. The depth of the groove is 2mm, and the distance between centers of the concentric V-shaped grooves is 2.81mm.

[0040] (c) Carry out magnesium swarf removal to the V-shaped groove machined by step (b), and carry out surface blasting treatment immediately after wiping clean with acetone. Quartz sand is used as the abrasive, the particle size is 30 mesh, the distance from the sandblasting nozzle to the blasting surface is 200mm, and the axis of the spray gun forms an angle of 85° with the surface.

[0041] (d) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com