Method for modification, moisture transfer, perspiration and finishing of aromatic polyamide fabric

An aromatic polyamide, moisture-wicking and sweat-wicking technology, which is applied in the fields of finishing, aromatic polyamide fabric modification, and aromatic polyamide fabric moisture-wicking and sweat-wicking finishing. It can solve the problem of difficult adsorption and fixation, and it is difficult to obtain good results and other problems, to achieve the effect of facilitating diffusion, coarsening fibers and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

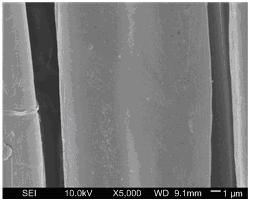

[0026] Put the polym-phenylene isophthalamide fabric into acetone for ultrasonic cleaning, take it out after 30 minutes, rinse it with tap water and dry it at 80°C.

[0027] Put the washed fabric into 20wt% DEET solution, treat it at 60°C for 60min, rinse it with tap water and dry it at 80°C.

[0028] Put the pretreated fabric into the working solution for moisture-wicking and sweat-wicking finishing. The bath ratio is 1:10. The temperature is raised from room temperature to 120°C at a rate of 1°C / min and kept for 30 minutes, and then the temperature is increased at a rate of 2°C / min. Cool the bath liquid to 60°C and discharge the working liquid. The formula of the working solution is: 3% o.w.f. HMW8870, 10g / L Cindye DNK, 0.1g / L emulsifier OP-9, and adjust the pH value to 4 with acetic acid.

[0029] Wash the fabric with 5g / L detergent JU at 30°C for 10 minutes, rinse with tap water, and dry at 80°C for 30 minutes until the fabric is dry.

Embodiment 2

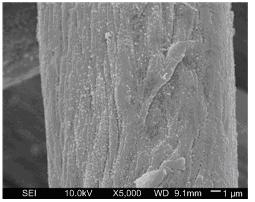

[0031] Put the polym-phenylene isophthalamide fabric into acetone for ultrasonic cleaning, take it out after 45 minutes, rinse it with tap water and dry it at 80°C.

[0032] The washed fabric was put into 60wt% DMSO solution, treated at 80°C for 45min, rinsed with tap water and dried at 80°C.

[0033] Put the pretreated fabric into the working solution for moisture-wicking and sweat-wicking finishing. The bath ratio is 1:20. The temperature is raised from room temperature at 2°C / min to 125°C and kept for 45 minutes. After that, the bath liquid is cooled at the same rate. Discharge the working fluid after reaching 60°C. The formula of the working solution is 3.5g / L JLSUN? STA, 20g / L Cindye DNK, 0.3g / L emulsifier OP-9, and the pH value is adjusted to 5 with acetic acid.

[0034]Wash the finished fabric with 3g / L detergent JU at 40°C for 8 minutes, rinse with tap water, and dry at 80°C for 30 minutes until the fabric is dry.

Embodiment 3

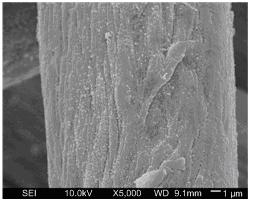

[0036] Put the polym-phenylene isophthalamide fabric into acetone for ultrasonic cleaning, take it out after 60 minutes, rinse it with tap water and dry it at 80°C.

[0037] Put the washed fabric into 70wt% NMP solution, treat it at 100°C for 60min, rinse it with tap water and dry it at 80°C.

[0038] Put the pretreated fabric into the working fluid for moisture-wicking and sweat-wicking finishing. The bath ratio is 1:30. The temperature is raised from room temperature to 130 °C at 3 °C / min and kept for 60 min. After that, the bath liquid is cooled at the same rate. Discharge the working fluid after reaching 70°C. The formula of the working solution is 5g / L HMW8870, 30g / L Cindye DNK, 0.5g / L emulsifier OP-9, and adjust the pH value to 6 with acetic acid.

[0039] Wash the finished fabric with 2g / L detergent JU at 50°C for 5 minutes, rinse it with tap water, and dry it at 80°C for 30 minutes until the fabric is dry.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com