Finishing liquor for realizing antibiosis of fabrics and preparation method of finishing liquor

A finishing liquid and fabric technology, applied in fiber treatment, textiles and papermaking, etc., can solve problems affecting application performance, reduce mechanical strength, unpleasant smell, etc., and achieve no side effects, high safety, high long-term bactericidal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

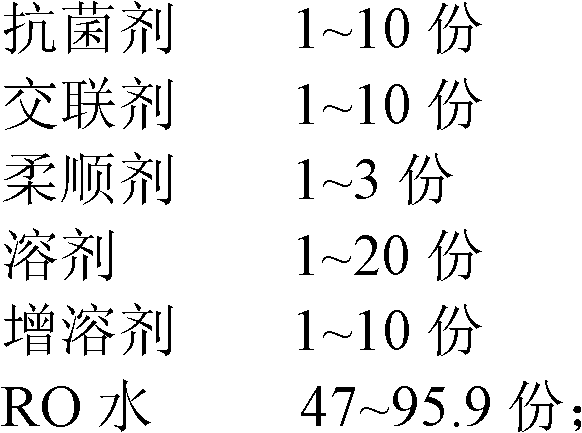

Method used

Image

Examples

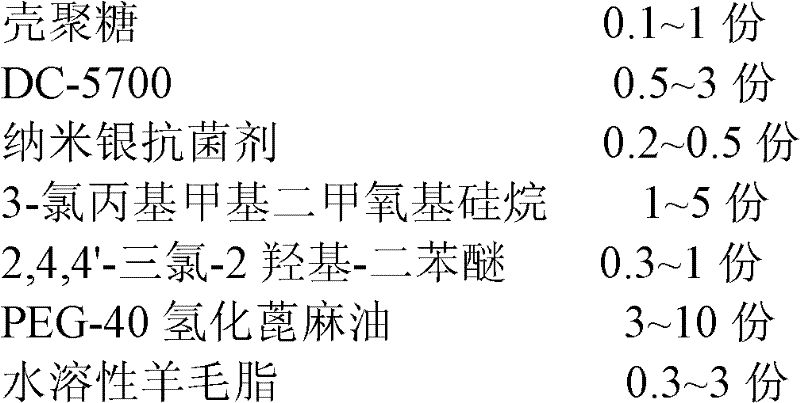

Embodiment 1

[0021] A preparation method of the above-mentioned finishing liquid, comprising the following steps,

[0022] 1) Take 0.1kg chitosan, add 10kg of RO water, add a few drops of acetic acid to dissolve chitosan in RO water, and form A solution;

[0023] 2) Take 0.3 kg of water-soluble lanolin, add 10 kg of RO water, heat in a water bath, and stir to dissolve the water-soluble lanolin to form B solution;

[0024] 3) Take 0.5kg DC-5700, 0.5kg nano-silver antibacterial agent, 1kg 3-chloropropylmethyldimethoxysilane, add 10kg of RO water, dissolve the above substances, and form C solution;

[0025] 4) Take 0.3kg 2,4,4'-trichloro-2-hydroxy-diphenyl ether, 3kg PEG-40 hydrogenated castor oil, and 10kg ethanol to dissolve the solid matter to form D solution;

[0026] 5) Mix A solution, B solution, C solution and D solution, and add RO water to make the total solution 100kg, stir and add defoamer T-1000A, and mix well.

Embodiment 2

[0028] A preparation method of the above-mentioned finishing liquid, comprising the following steps,

[0029] 1) Take 1kg of chitosan, add 10kg of RO water, drop a few drops of acetic acid to dissolve chitosan in RO water, and form A solution;

[0030] 2) Take 1 kg of water-soluble lanolin, add 10 kg of RO water, heat in a water bath, and stir to dissolve the water-soluble lanolin to form B solution;

[0031] 3) Take 1kg of DC-5700, 0.5kg of nano-silver antibacterial agent, 5kg of 3-chloropropylmethyldimethoxysilane, add 10kg of RO water, dissolve the above substances, and form C solution;

[0032] 4) Take 1kg of 2,4,4'-trichloro-2-hydroxy-diphenyl ether, 10kg of PEG-40 hydrogenated castor oil, and 10kg of ethanol to dissolve the solid matter to form D solution;

[0033] 5) Mix A solution, B solution, C solution and D solution, and add RO water to make the total solution 100kg, stir and add defoamer T-1000A, and mix well.

Embodiment 3

[0035] A preparation method of the above-mentioned finishing liquid, comprising the following steps,

[0036] 1) Take 0.8kg of chitosan, add 10kg of RO water, drop a few drops of acetic acid to dissolve chitosan in RO water, and form A solution;

[0037] 2) Take 3kg of water-soluble lanolin, add 10kg of RO water, heat in a water bath, and stir to dissolve the water-soluble lanolin to form B solution;

[0038] 3) Take 3kg DC-5700, 0.3kg nano-silver antibacterial agent, 3kg 3-chloropropylmethyldimethoxysilane, add 10kg of RO water, dissolve the above substances, and form C solution;

[0039] 4) Take 0.5kg 2,4,4'-trichloro-2-hydroxy-diphenyl ether, 5kg PEG-40 hydrogenated castor oil, and 10kg ethanol to dissolve the solid matter to form D solution;

[0040] 5) Mix A solution, B solution, C solution and D solution, and add RO water to make the total solution 100kg, stir and add defoamer T-1000A, and mix well.

[0041] The present invention is not limited to the above-mentioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com