Acoustic emission device and method for detecting destructive failure of carbon fiber composite material

A composite material, acoustic emission technology, applied in the direction of material analysis using acoustic emission technology, can solve the problems of expensive equipment, low sensitivity of small defects, inclusions, etc., to achieve the effect of simple operation, continuous real-time signal feedback, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

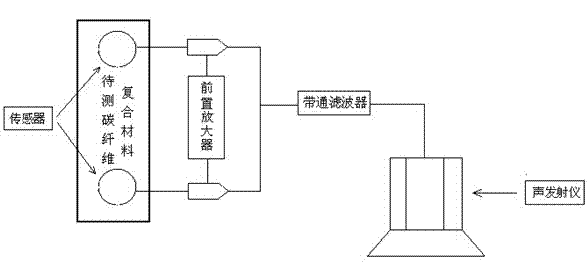

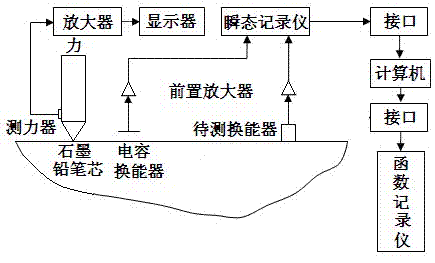

[0035] The carbon fiber composite material damage failure acoustic emission detection method of the present invention comprises the following steps:

[0036] 1. Determination and installation of sensor spacing

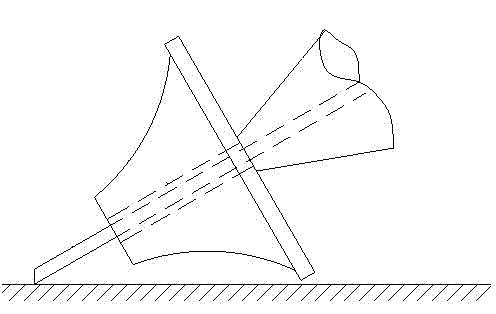

[0037] The distance between the two sensors is determined by the pencil lead analog acoustic emission signal device. The two sensors are fixed on the surface of the carbon fiber composite material, and the coupling agent is filled between the sensor and the carbon fiber composite material to be tested, so that there is good acoustic coupling between the two. The coupling agent can be petroleum jelly, but is not limited thereto.

[0038] 2. Obtaining acoustic emission signals of composite material failure failure

[0039] Use the electro-hydraulic servo material testing system (MTS810-25ton) to test various Tensile tests were carried out on laminate samples with ply angles and different hole sizes, and the 48-channel acoustic emission instrument produced by the Americ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com