Nursing and / or make-up cosmetic composition structured with silicone polymer

A cosmetic composition and composition technology, applied in the direction of cosmetics, cosmetics, body powder, etc., can solve the problems of preparation application difficulties and achieve the effect of enhancing retention and improving gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

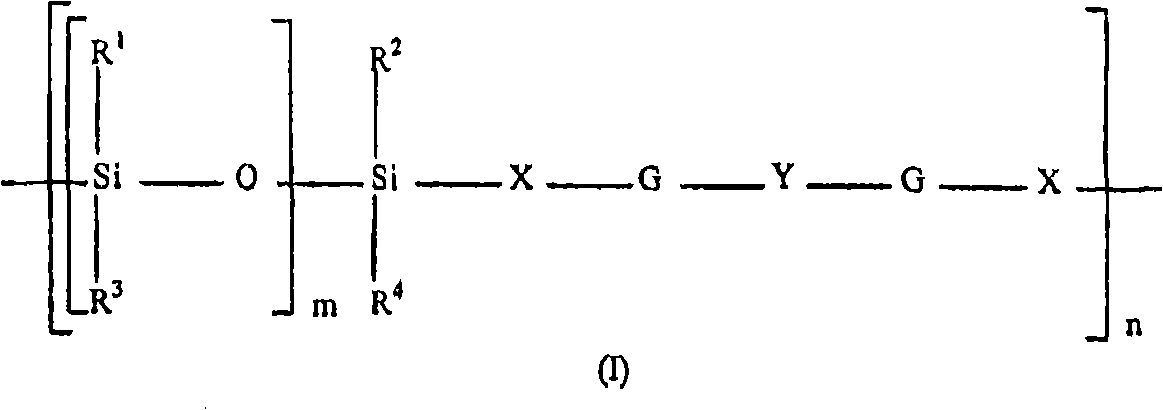

Method used

Image

Examples

Embodiment 1

[0464] Embodiment 1 (comparison)

[0465] In this example, which does not follow the invention, cosmetic formulations for the lips and face are prepared from silicone only with silicone polyamide as structuring agent and phenylated silicone as oil.

[0466] The formulation is then colored and cast in cans.

[0467] The composition of the prepared formulation is given below:

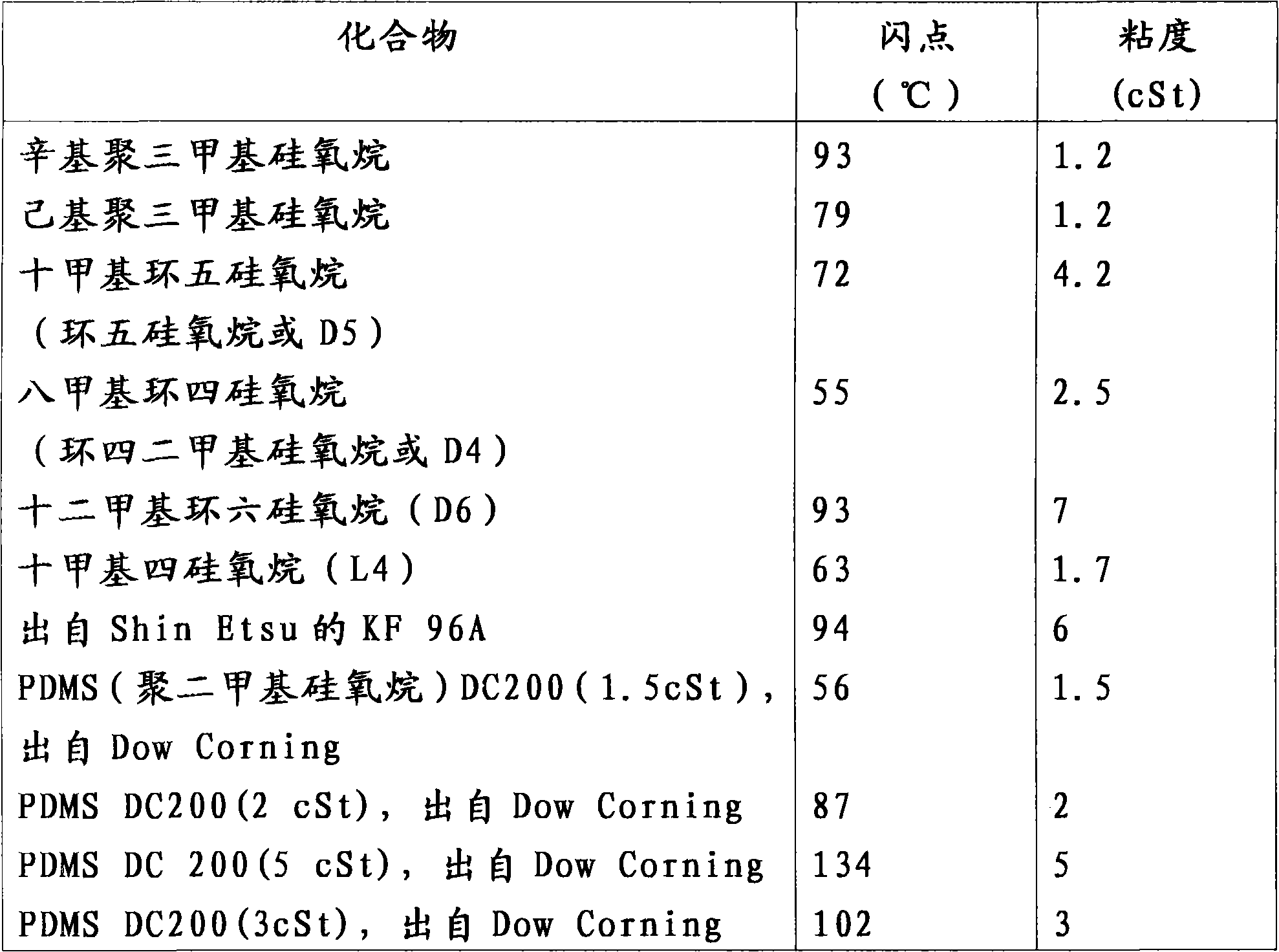

[0468]

[0469] *DP: degree of polymerization

[0470] The silicone polymer, melted at 110° C., is mixed with a portion of the oil in order to obtain a liquid mixture. Meanwhile, the pigments are ground in the remaining portion of the oil. Finally, the pigmented ground product was mixed with the oil+gelling agent mixture at 110°C.

[0471] The deposits obtained from the strip on the hands are fine and uneven.

[0472]In conclusion, it appears that the formulation prepared in this comparative example was hard, depositing only minimal color during application (very difficult).

Embodiment 2

[0474] In this example according to the invention, a cosmetic preparation with a composition similar to claim 1 was prepared, except that 20% by mass of the compound according to the invention, which lowers the melting temperature of the polymer, octyldodecanol, was added to the preparation middle.

[0475] The composition of the prepared formulation is given below:

[0476]

[0477] *DP: degree of polymerization

[0478] The silicone polymer, melted at 110° C., is mixed with a portion of silicone oil and octyldodecanol in order to obtain a liquid mixture. Meanwhile, the pigments are ground in the remaining portion of the oil. Finally, the pigmented ground product was mixed with the oil+gelling agent mixture at 110°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com