Microporous gas distributor of ceramic membrane

A gas distributor, ceramic membrane technology, applied in the chemical method, water aeration, separation method, etc. to make liquid react with gas medium, can solve the problems of shortened service life, limited pressure resistance, limited use range, etc. Achieve stable operation, reduce operating costs and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

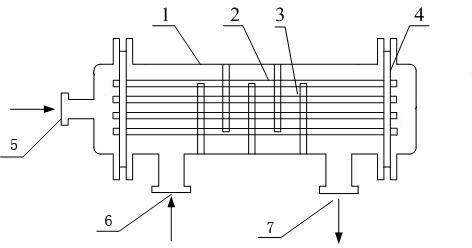

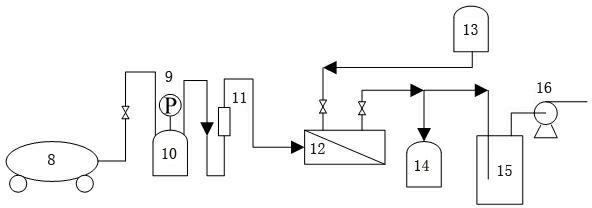

[0032] Taking the measurement of oxygen content in water as an example, the ceramic membrane element 2 made of alumina sintered has a porosity of 36%, an average pore diameter of 50nm, and an odd number of separators 3, and the liquid inlet 6 and the liquid outlet 7 are in the The same side of housing 1. The gas is transported by the air compressor 8 and passes through the buffer tank 10 to stabilize the flow rate. The pipeline between the air compressor 8 and the buffer tank 10 is equipped with a pressure gauge 9 for easy observation at any time, and then the gas flow rate is adjusted through the rotameter 11 reached the experimental range value. When the gas pressure reaches 0.1Mpa, it enters the ceramic membrane microporous gas distributor 12 from the air inlet 5, diffuses into fine and uniform bubbles through the micropores on the ceramic membrane element 2, and the clear water in the feed liquid tank 13 is fed by the liquid The port 6 enters the shell 1 and mixes and...

Embodiment 2

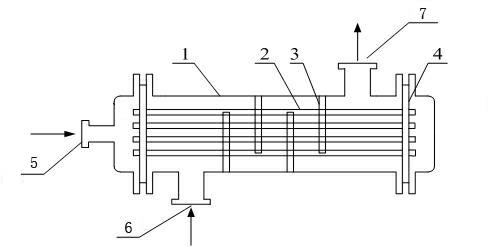

[0034] Taking the sodium sulfite air oxidation method to measure the dissolved amount of sodium sulfite as an example, the ceramic membrane element 2 formed by sintering zirconia has a porosity of 50%, an average pore diameter of 800nm, and an even number of separators 3, liquid inlets 6 and discharge ports. The liquid ports 7 are on different sides of the housing 1 . The gas is transported by the air compressor 8 and passes through the buffer tank 10 to stabilize the flow rate. The pipeline between the air compressor 8 and the buffer tank 10 is equipped with a pressure gauge 9 for easy observation at any time, and then the gas flow rate is adjusted through the rotameter 11 reached the experimental range value. When the gas pressure reaches 0.8Mpa, it enters the ceramic membrane microporous gas distributor 12 from the air inlet 5, and diffuses into fine and uniform bubbles through the micropores on the ceramic membrane element 2. The port 6 enters the shell 1 and mixes and co...

Embodiment 3

[0036] Taking the measurement of oxygen content in water as an example, the ceramic membrane element 2 made of alumina sintered has a porosity of 30%, an average pore diameter of 100nm, and an odd number of separators 3, and the liquid inlet 6 and the liquid outlet 7 are in the The same side of housing 1. The gas is transported by the air compressor 8 and passes through the buffer tank 10 to stabilize the flow rate. The pipeline between the air compressor 8 and the buffer tank 10 is equipped with a pressure gauge 9 for easy observation at any time, and then the gas flow rate is adjusted through the rotameter 11 reached the experimental range value. When the gas pressure reaches 0.1Mpa, it enters the ceramic membrane microporous gas distributor 12 from the air inlet 5, diffuses into fine and uniform bubbles through the micropores on the ceramic membrane element 2, and the clear water in the feed liquid tank 13 is fed by the liquid The port 6 enters the shell 1 and mixes an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com