Feeding mechanism for electric arc cutting tool electrode of deep water oil well casing

A tool electrode and oil well casing technology is applied in the field of deepwater oil well casing arc cutting tool electrode feeding mechanism, which can solve the problems of small arc cutting cutting force, etc., and achieves improved cutting speed, narrow slit and stable servo feeding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

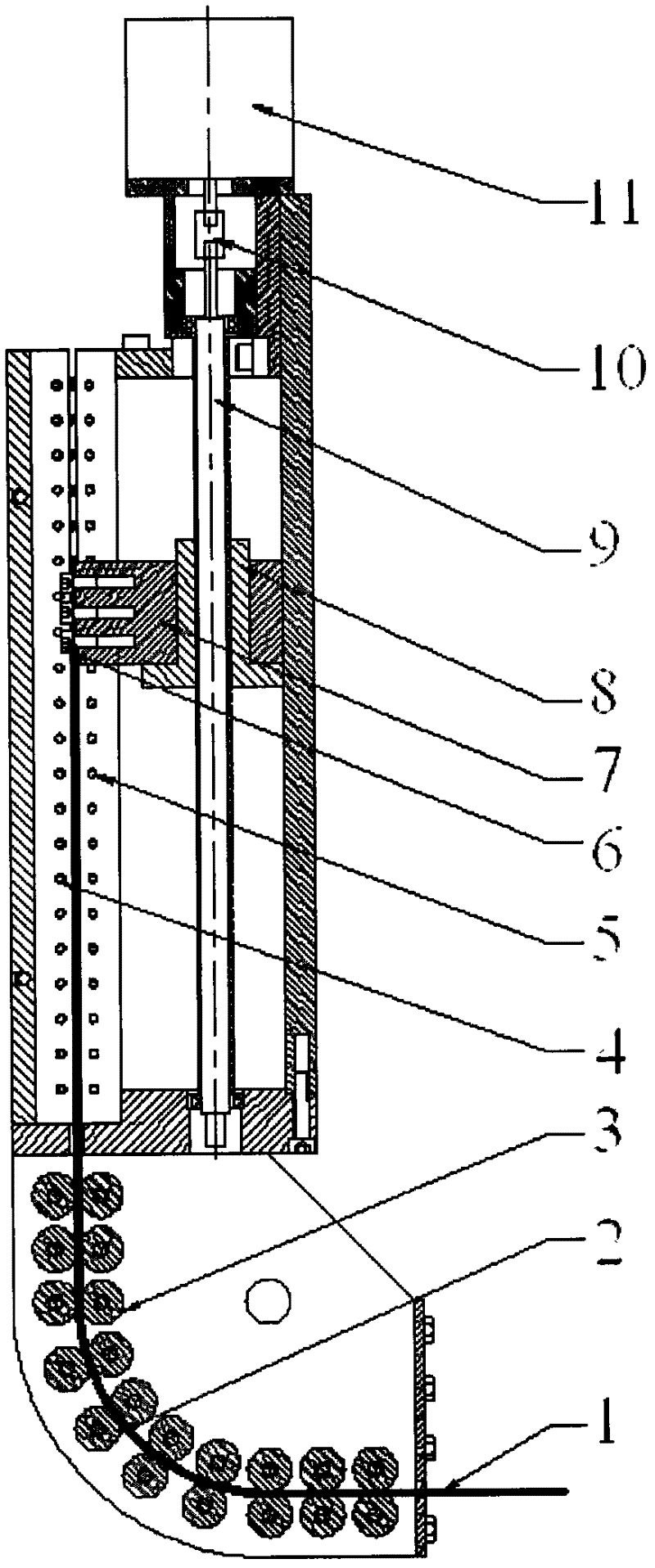

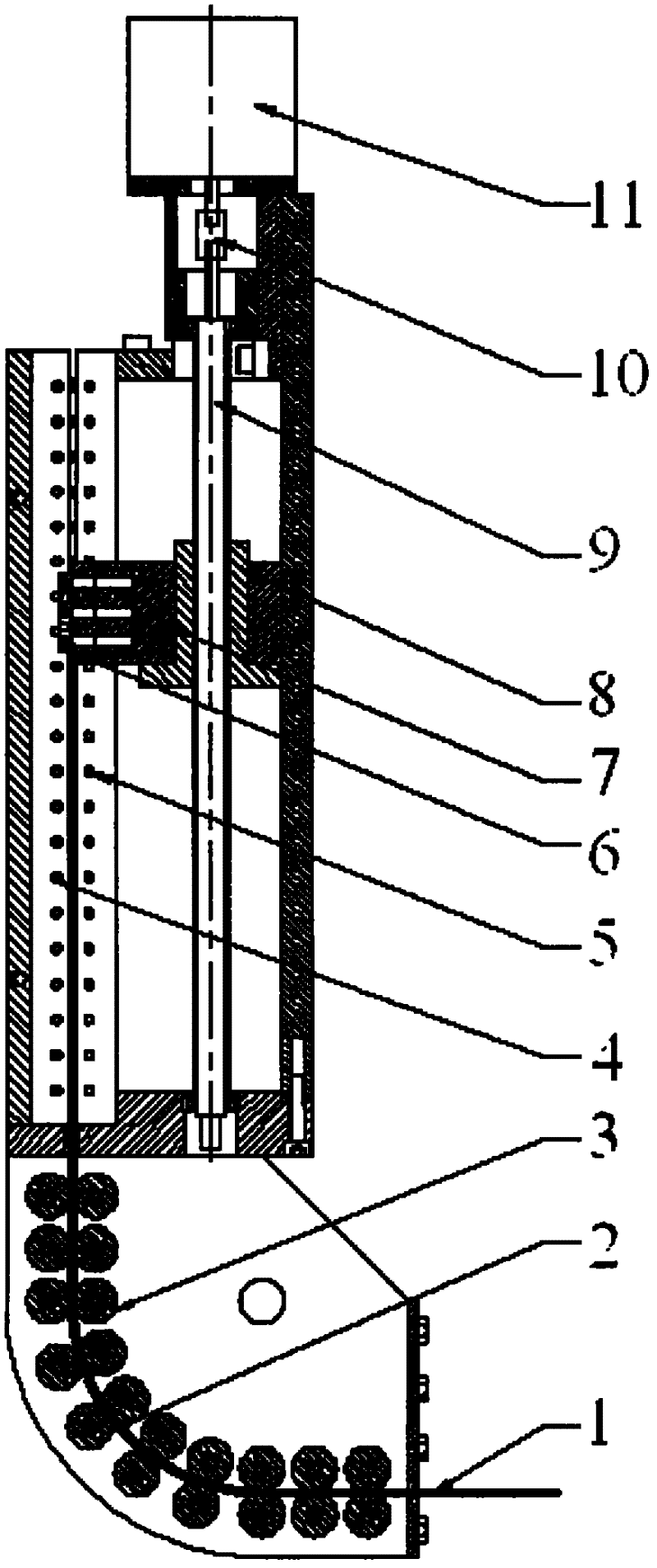

[0011] see figure 1 . The deep-water oil well casing arc cutting tool electrode feeding mechanism of the present invention is mainly composed of a strip tool electrode 1, an outer arc guide wheel set 2, an inner arc guide wheel set 3, an outer linear guide wheel set 4, and an inner linear guide wheel set 5. Tool electrode fixing bolt 6, slider 7, lead screw nut 8, ball screw 9, coupling 10 and servo motor 11.

[0012] The rotating shaft of the servo motor 11 is connected with the ball screw 9 through the coupling 10, and the servo motor 11 drives the ball screw 9 to perform servo rotation; The reverse rotation drives the lead screw nut 8 to move up and down; the slider 7 is fixed with the lead screw nut 8 and moves up and down together with the lead screw nut 8; the tool electrode fixing bolt 6 fixes the strip tool electrode 1 on the slider 7 ; The outer linear guide wheel group (4) and the inner linear guide wheel group (5) are all made up of rollers with the same diameter....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com