Knife holder of machine tool

A tool holder and machine tool technology, which is applied in the new structure field of machine tool holders, can solve the problems of complex manufacturing and assembly process, large overturning moment of cutting force, complex tool holder structure, etc., and achieve simplification of assembly process, reduction of overturning moment, tool The effect of simple frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below through specific examples.

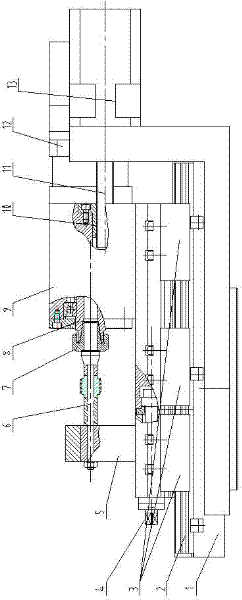

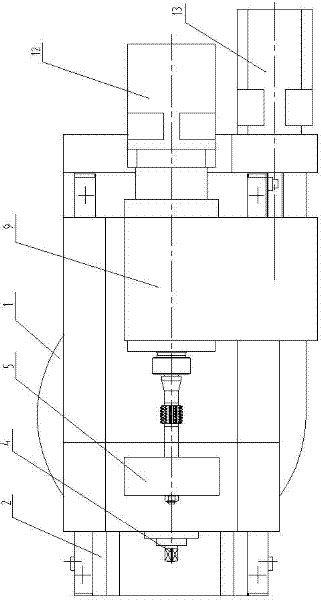

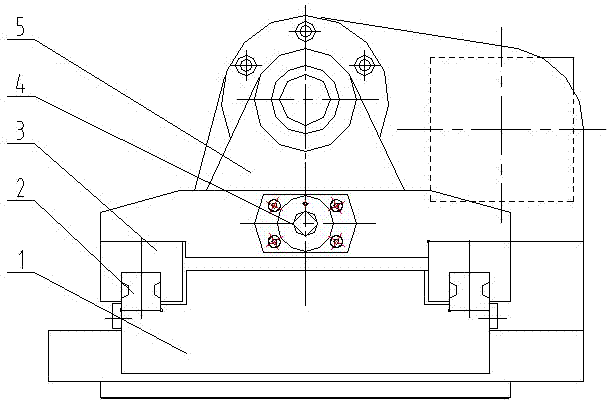

[0016] Such as Figure 1 to Figure 3 As shown, a machine tool holder is used for a gear hobbing machine or a worm wheel grinding machine, and has a tool holder housing 1, a bracket 5, a main shaft 8, a main shaft slide plate seat 9, a main shaft driving system 12, a knife shifting motor 13 and is installed on The tool mandrel 6 between the bracket 5 and the main shaft 8 is provided with a sliding guide rail 2 on the tool post housing 1, and the lower ends of the bracket 5 and the main shaft skateboard seat 9 are flat structures, and the bracket 5 and the main shaft skateboard seat 9 are respectively The slider 3 is supported on the sliding guide rail 2 , and the bracket locking mechanism 4 is installed between the bracket 5 and the main shaft skateboard seat 9 . That is to say, the bracket 5 and the main shaft skateboard seat 9 are supported on the same sliding guide rail pair on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com