Plywood with twist resistance and high strength and manufacturing method thereof

A manufacturing method and high-strength technology, applied in the field of plywood, can solve the problems of poor anti-distortion performance and high formaldehyde content of the board, and achieve the effects of high bonding strength, simple production process and economical production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

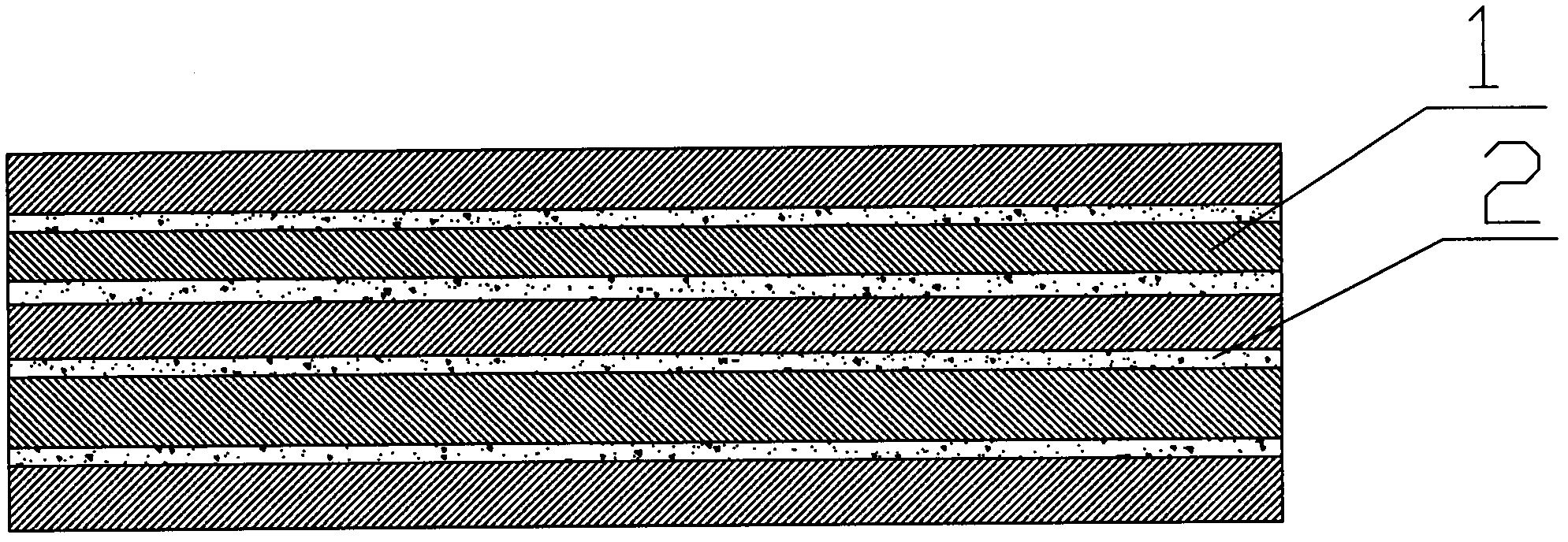

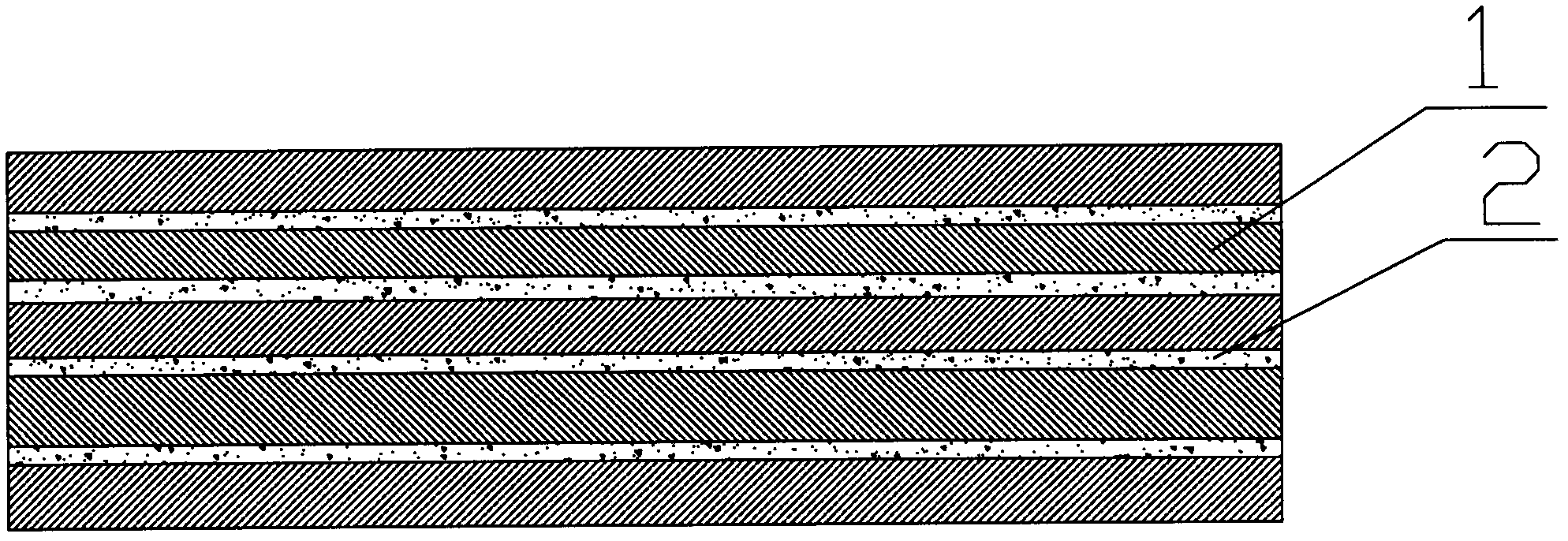

[0025] As shown in the accompanying drawings, a twist-resistant high-strength plywood is a five-ply board, including five layers of superimposed veneers 1, the textures of adjacent veneers are perpendicular to each other, and there is an adhesive layer 2 between adjacent veneers, so The above-mentioned adhesive layer is a zero-formaldehyde hot-melt film.

[0026] Anti-twisting high-strength plywood process:

[0027] Select core board → dry moisture content below 12% → slope (slope at both ends to facilitate splicing and enhance layering) → combination (core board, hot-melt film) → pre-press (0.67Mpa) → hot press (280°C , 2Mpa)→cooling (cold water circulation)→puttying→thickness sanding→sawing edge→smearing concealer→cold pressing (0.67Mpa)→veneering→hot pressing→sawing edge.

[0028] The plywood made by this method, after testing:

[0029] (1) The bonding strength is high, and it can pass the bonding strength test of Type I wood-based panels / WBP grade and Type I wood-based p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com