Biological thickening device for reducing pollutants in coal chemical industry wastewater

A coal chemical wastewater and biological enrichment technology, applied in the field of sewage treatment, can solve the problems of treatment accidents and substandard effluent, and achieve the effects of saving oxygen supply, saving operating costs, and saving alkalinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

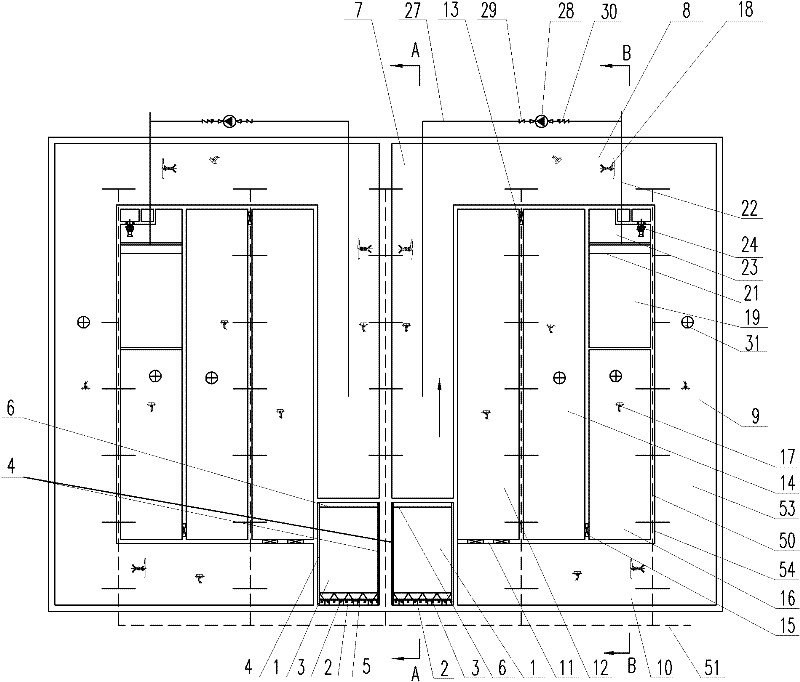

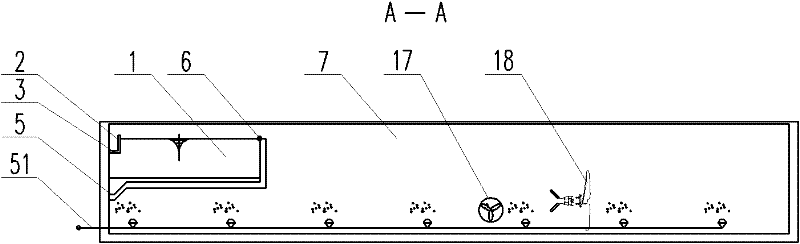

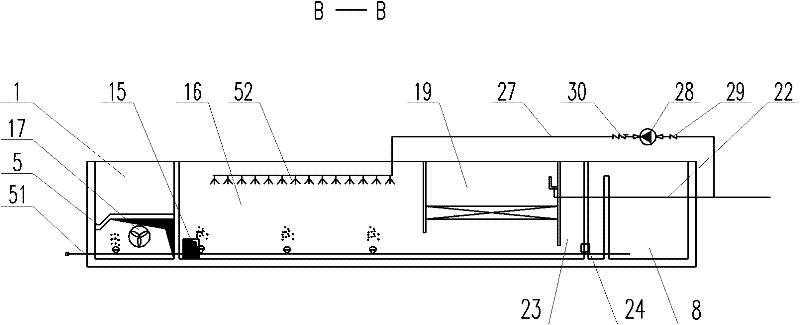

[0013] Specific implementation mode one: combine Figure 1-Figure 5Explain, a kind of biological enrichment device for reducing coal chemical wastewater pollutants in this embodiment, the biological enrichment device includes at least one pool body 53, submersible sludge pump 24, distribution channel 2, first outlet weir 6, second Two outlet weirs 21, drainage pipes 22, branch pipes 27, aeration branch pipes 50, main aeration pipes 51, backflow defoaming water pumps 28, multiple agitators 17, multiple underwater thrusters 18 and multiple nozzles 52, pool body 53 is added with suspended filler 31, the bottom of the pool body 53 is closed, and the pool body 53 is divided into three areas and seven corridors by multiple partition walls 54; the three areas are anaerobic sedimentation area 1, inclined pipe Sedimentation zone 19 and return sludge zone 23, the seven corridors are the first longitudinal corridor 7, the first transverse corridor 8, the second longitudinal corridor 9, t...

specific Embodiment approach 2

[0016] Specific implementation mode two: combination figure 1 and image 3 Note that the submersible sludge pump 24 in this embodiment is fixed on the front wall in the return sludge area 23; the branch pipe 27 is equipped with a butterfly valve 29 and a check valve 30, and the check valve 30 is located between the return flow defoaming water pump 28 and the drain. Between the pipes 22 , a butterfly valve 29 is located between the backflow defoaming water pump 28 and the other end of the drain pipe 22 . Such setting can realize the effective control of returning sludge and water flow. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: combination figure 1 Note that the number of pool bodies 53 in this embodiment is two, and the two pool bodies 53 are arranged side by side and fixedly connected as one, and the two pool bodies 53 are arranged symmetrically with respect to the center line in the length direction of the two pool bodies. Such setting can improve the wastewater treatment efficiency. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com