Method for manufacturing doped optical fibre preform by MCVD (modified chemical vapour deposition)

A technology for doping optical fibers and preforms, which is applied to manufacturing tools, glass manufacturing equipment, etc., can solve the problems of large consumption of rare earth solution and longitudinal unevenness of rare earth doping, saving time, uniform distribution, and reducing manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

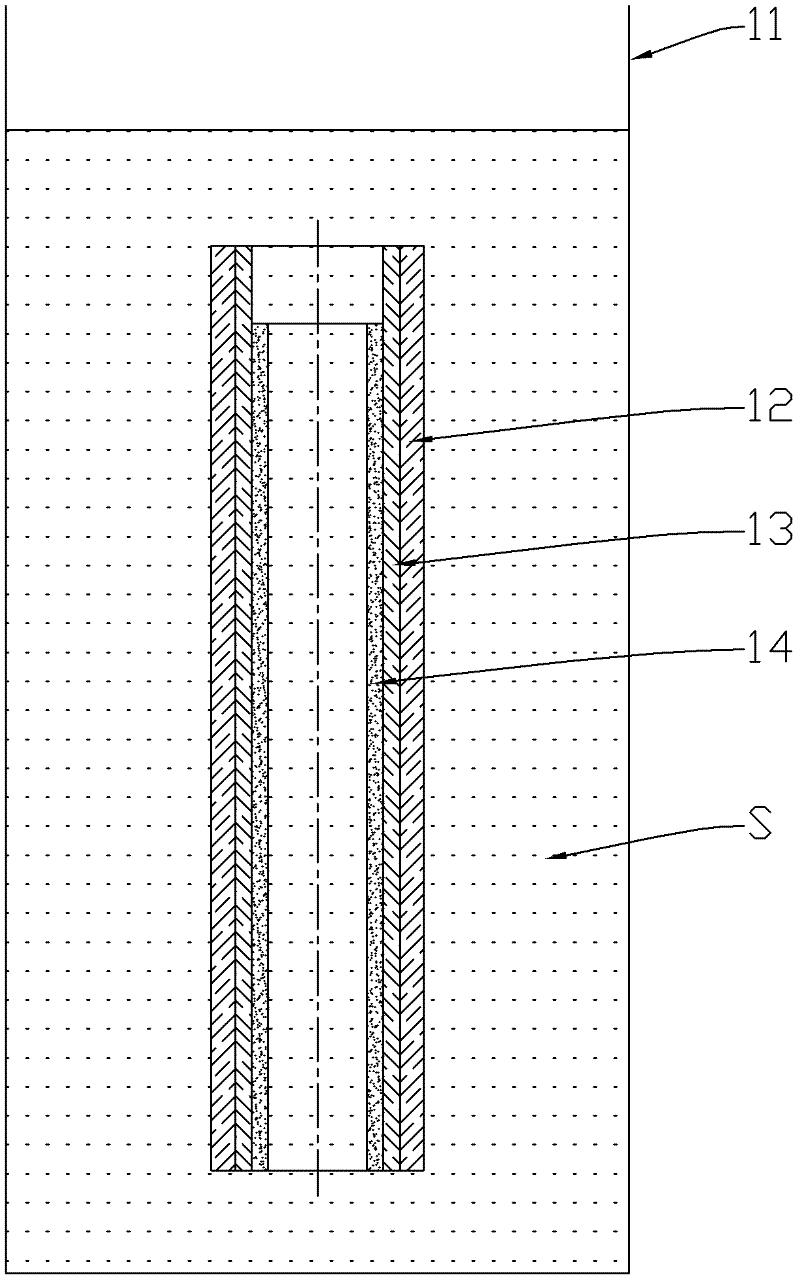

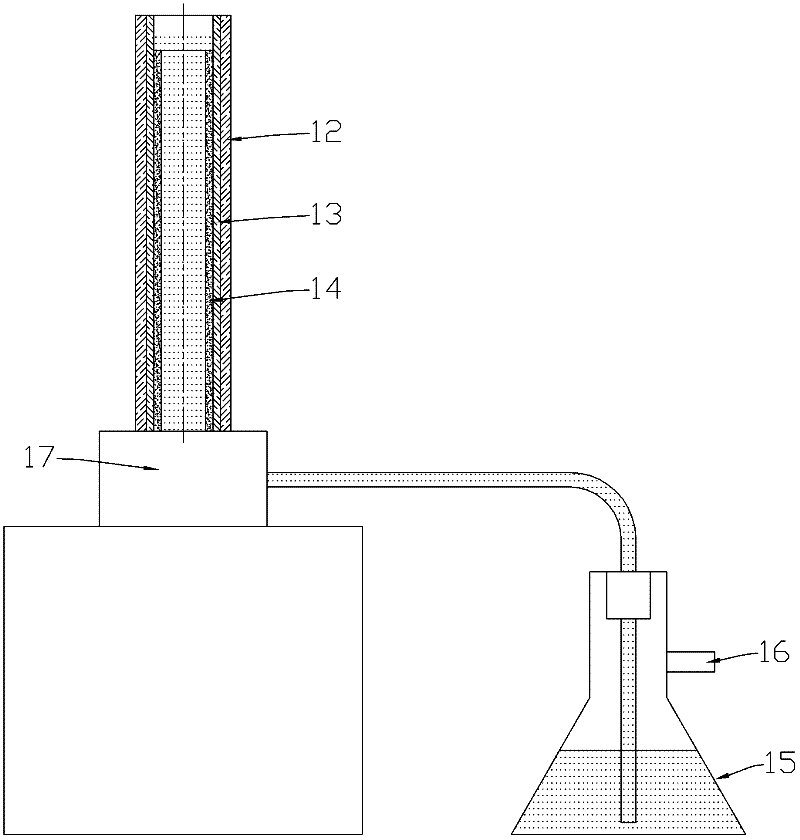

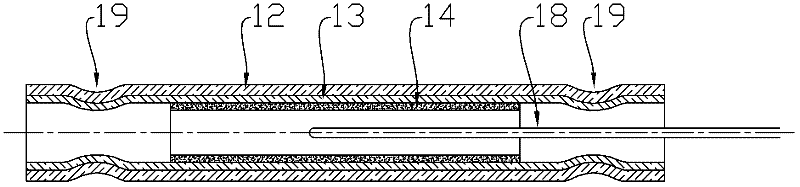

[0061] The quartz deposition tube 12 is subjected to high temperature (1800-2100° C.) flame polishing to eliminate scratches, impurities, surface unevenness and shrinkage bubbles on the surface of the deposition tube 12 . Deposit 10 layers containing SiO on the inner surface of the deposition tube 12 at 1870°C (generally within the temperature range of 1800-2000°C) 2 -P 2 o 5 -F's inner cladding 13 (the 10 layers of deposition are that the blowtorch 3 moves 10 times from the inlet end of the deposition tube 12 to the outlet end and deposits 10 times, and the actually formed 10-layer inner cladding 13 has no limit on the cross section , represented as a continuous layer, the deposition of 10 layers mentioned in the following examples is the same concept). Reverse deposition at 1550°C with SiCl 4 and POCl 3 The gas deposits a core layer 14 of loose soot. Then move the torch 3 to the inlet end of the deposition tube 12, fix the position of the torch 3 and heat the deposition...

Embodiment 2

[0063] The quartz deposition tube 12 is subjected to high-temperature flame polishing to eliminate scratch impurities, surface unevenness and shrinkage bubbles on the surface of the deposition tube 12 . Deposit 10 layers containing SiO on the inner surface of the deposition tube 12 at 1870°C 2 -P 2 o 5 - Inner cladding 13 of F. Next, the torch 3 is moved to the inlet end of the deposition tube 12, and the position of the torch 3 is fixed to heat the deposition tube 12 so that its inner diameter shrinks. Reduce the deposition temperature to 1250°C and feed SiCl 4 、GeCl 4 and POCl 3 The gas deposits the loose soot core layer 14 so that the inner diameter of the loose soot core layer 14 of the deposition tube is greater than or equal to the inner diameter of the constriction 19 . Then the torch 3 is moved to the tail end of the deposition tube 12, and the temperature is raised to break the deposition tube 12, so that the tail end of the deposition tube 12 is closed. Remove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com