Water-retaining and cooling material for road as well as preparation and construction methods for same

A water-retaining material and road-use technology, applied in the direction of roads, roads, climate change adaptation, etc., can solve the problem that the cooling advantages of the penetrating water-retaining pavement structure cannot be fully reflected, the water-absorbing capacity cannot meet the requirements of water-retaining pavement to store water, and the water-retaining material can retain water. Poor performance and other problems, to achieve the effect of alleviating the urban heat island effect, facilitating promotion and application, and good affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

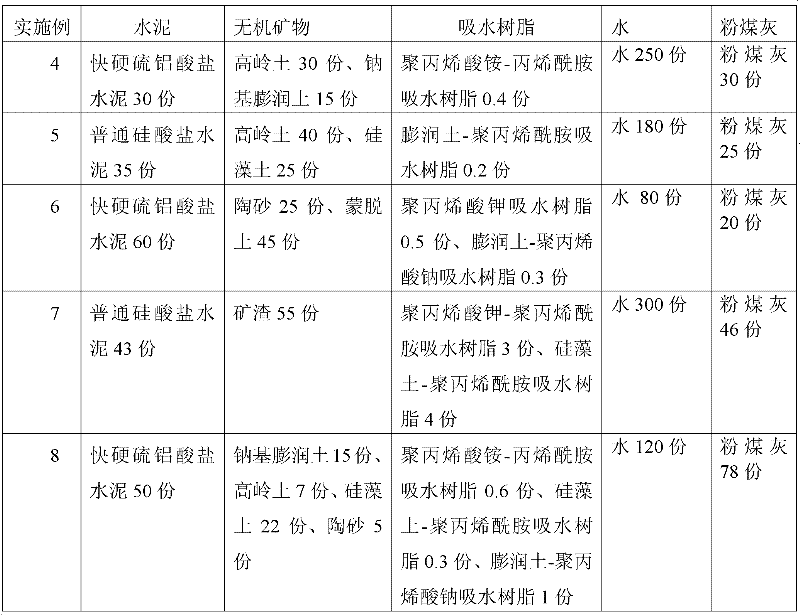

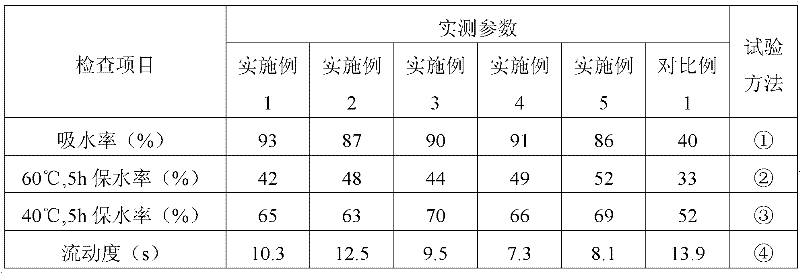

Examples

Embodiment 1

[0031] A water-retaining and cooling material for roads is prepared as follows:

[0032] ① Weigh the raw materials according to the following ratio

[0033] Rapid hardening sulfoaluminate cement 30Kg,

[0034] Diatomaceous earth 60Kg,

[0035] Sodium polyacrylate water absorbent resin 0.3Kg,

[0036] Class III fly ash 30Kg,

[0037] Water 200Kg

[0038] ②Preparation and construction process

[0039]1: Put 0.3Kg of the above-mentioned sodium polyacrylate water-absorbing resin into a stirring container and add 100Kg of water, stir for 120s to make it fully and evenly absorb water, then take it out, filter out the water with a 100-mesh screen, and take the part on the screen for later use;

[0040] 2: Next, add 60Kg of diatomaceous earth, 30Kg of grade III fly ash, and 100Kg of water into the reaction vessel, and stir at room temperature for 90s;

[0041] 3: Add 30Kg of the above-mentioned rapid-hardening sulfoaluminate cement into the reaction vessel in step 2, and stir fo...

Embodiment 2

[0045] A water-retaining and cooling material for roads is prepared as follows:

[0046] ① Weigh the raw materials according to the following ratio

[0047] Rapid hardening sulfoaluminate cement 40Kg,

[0049] Diatomaceous earth-sodium polyacrylate water-absorbing resin 0.3Kg,

[0050] Fly ash 50Kg,

[0051] Water 200Kg

[0052] ②Preparation and construction process

[0053] 1: Put 0.3Kg of the above-mentioned diatomite-sodium polyacrylate water-absorbing resin into a stirring container and add 100Kg of water, stir for 120s to make it fully and evenly absorb water, then take it out, filter out the water with a 100-mesh sieve, and take the sieve The upper part is spare;

[0054] 2: Next, add 30Kg of sodium-based bentonite, 50Kg of fly ash, and 100Kg of water into the reaction vessel, and stir at room temperature for 90s;

[0055] 3: Add 40Kg of the above-mentioned rapid-hardening sulfoaluminate cement into the reaction vessel in step 2, an...

Embodiment 3

[0059] A road water-retaining material, prepared as follows:

[0060] ① Weigh the raw materials according to the following ratio

[0061] Ordinary Portland cement 30Kg,

[0062] Diatomaceous earth 60Kg,

[0063] Polymethyl methacrylate water-absorbent resin 0.5Kg,

[0064] Fly ash 35Kg,

[0065] Water 200Kg,

[0066] ②Preparation and construction process

[0067] 1: Put 0.5Kg of the above-mentioned polymethyl methacrylate water-absorbing resin into a stirring container and add 100Kg of water, stir for 120s to make it fully and evenly absorb water, then take it out, filter out the water with a 100-mesh screen, and take it out on the sieve partial spare;

[0068] 2: Add 60Kg of diatomite, 35Kg of fly ash, and 100Kg of water into the reaction vessel, and stir at room temperature for 90s;

[0069] 3: Add 30Kg of ordinary Portland cement to the reaction vessel in step 2, add an appropriate amount of water and stir for 120s at room temperature;

[0070] 4: Finally, add the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com