Method for preparing methanol and dimethyl ether by taking calcium carbide furnace tail gas and sodium chlorate tail gas as well as other hydrogen-containing gas sources as raw materials

A technology of calcium carbide furnace tail gas and dimethyl ether, which is applied to chemical instruments and methods, dehydration of hydroxyl-containing compounds to prepare ether, ether preparation, etc., can solve the problems of lack of implementation and difficulty in purifying calcium carbide furnace tail gas, and achieve extreme With market competitiveness, obvious energy saving effect and low product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

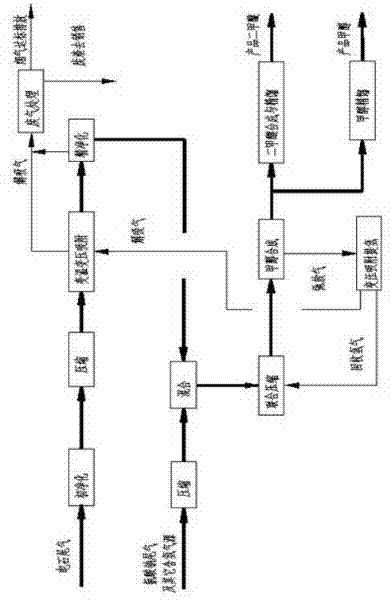

[0040] In this embodiment, the method for producing methanol and dimethyl ether using calcium carbide furnace tail gas and sodium chlorate tail gas as raw materials, the main steps include: calcium carbide furnace tail gas undergoes wet desulfurization, temperature swing adsorption (TSA) and pressure swing adsorption (PSA) purification, Fine purification; mixing and compression with hydrogen purified from sodium chlorate tail gas; methanol synthesis and methanol dehydration to produce dimethyl ether; methanol synthesis gas relaxation gas hydrogen extraction and waste gas treatment. Its flowchart is as follows: figure 1 As shown, the specific processing methods of each step are as follows:

[0041] (1) Wet desulfurization of calcium carbide furnace tail gas (ie figure 1 rough purification in

[0042] The method of wet PDS desulfurization is used to remove most of the inorganic sulfur, part of organic sulfur and hydrogen cyanide in the tail gas of the raw material calcium ca...

Embodiment 2

[0065] In this embodiment, the method for producing methanol and dimethyl ether using calcium carbide furnace tail gas and sodium chlorate tail gas as raw materials, the main steps include: calcium carbide furnace tail gas undergoes wet desulfurization, temperature swing adsorption (TSA) and pressure swing adsorption (PSA) purification, Fine purification; mixing and compression with hydrogen purified from sodium chlorate tail gas; methanol synthesis and methanol dehydration to produce dimethyl ether; methanol synthesis relaxation gas hydrogen extraction and waste gas treatment. Its flowchart is as follows: figure 1 As shown, the specific processing methods of each step are as follows:

[0066] (1) Wet desulfurization of calcium carbide furnace tail gas (ie figure 1 rough purification in

[0067] The method of wet PDS desulfurization is used to remove most of the inorganic sulfur, part of organic sulfur and hydrogen cyanide in the tail gas of the raw material calcium carbid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com