Preparation method of ultraviolet-curable organosilicone-modified pressure-sensitive adhesive

A silicone, pressure-sensitive adhesive technology, applied in the direction of adhesives, graft polymer adhesives, adhesive types, etc., can solve problems such as energy waste and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

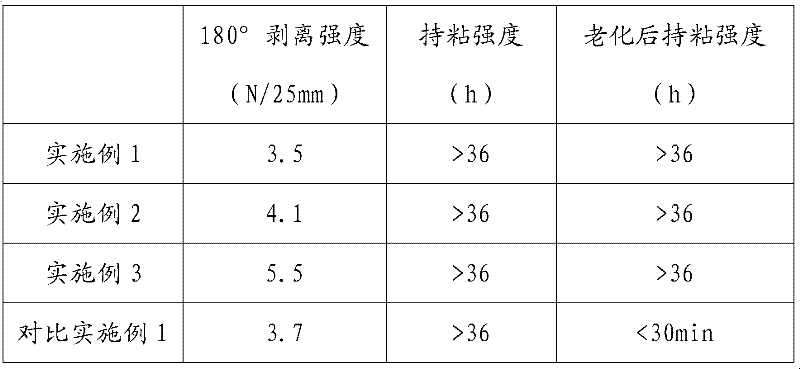

Examples

Embodiment 1

[0038] Add 120 grams of biscarboxysilane oil (Dow Corning BY16-201) with a hydroxyl value of 60 into the reactor together with 17 grams of isophorone diisocyanate, add 0.1 grams of dibutyltin dilaurate as a catalyst, and react at 75 ° C for 2.5 hour, add 3.5 g of hydroxyethyl acrylate and 0.3 g of p-hydroxyanisole, continue to react at 75 ° C for 2 hours, then add 30 g of isooctyl acrylate, stir evenly, cool and discharge the prepolymer [1].

[0039] Mix 30 grams of C5 petroleum resin (softening point 90°C) with 4 grams of tetraethylene glycol diacrylate and 20 grams of tetrahydrofuryl acrylate, heat to 40°C, stir to dissolve, add the above prepolymer [1] 100 grams, add 5 grams of 2-hydroxy-methylphenylpropan-1-one as a photoinitiator, mix to maintain the viscosity of the system at 2000mPa.s, evenly apply it on a PET film, and place it under a 2Kw ultraviolet lamp for 15 cm Cured for 50 seconds.

Embodiment 2

[0041] 150 grams of biscarboxysilane oil (Shin-Etsu KF6002) with a hydroxyl value of 35 and 15.6 grams of isophorone diisocyanate were added to the reactor, and 0.2 grams of dibutyltin dilaurate was added as a catalyst, and reacted at 75 ° C for 2.5 hours. Add 6.2 g of hydroxyethyl acrylate and 0.3 g of p-hydroxyanisole, continue to react at 75°C for 2 hours, then add 30 g of isooctyl acrylate, stir evenly, cool and discharge to form a prepolymer [2].

[0042]Mix 30 grams of C5 petroleum resin (softening point 90°C) with 4 grams of tetraethylene glycol diacrylate and 20 grams of tetrahydrofuryl acrylate, heat to 40°C, stir to dissolve, add the above prepolymer [2] 100 grams, add 5 grams of 2-hydroxy-methylphenylpropan-1-one as a photoinitiator, mix to maintain the viscosity of the system at 3000mPa.s, evenly apply it on a PET film, and place it under a 2Kw ultraviolet lamp for 15 cm Cured for 50 seconds.

Embodiment 3

[0044] Add 160 grams of biscarboxysilane oil (Shin-Etsu KF6003) with a hydroxyl value of 22 into the reactor together with 12.6 grams of isophorone diisocyanate, add 0.2 grams of dibutyltin dilaurate as a catalyst, and react at 75 ° C for 2.5 hours, Add 6.7 g of hydroxyethyl acrylate and 0.3 g of p-hydroxyanisole, continue to react at 75°C for 2 hours, then add 30 g of isooctyl acrylate, stir evenly, cool and discharge to form a prepolymer [3].

[0045] Mix 30 grams of C5 petroleum resin (softening point 90°C) with 4 grams of tetraethylene glycol diacrylate and 20 grams of tetrahydrofuryl acrylate, heat to 40°C, stir to dissolve, add the above prepolymer[3] 100 grams, add 5 grams of 2-hydroxy-methylphenylpropan-1-one as a photoinitiator, mix to maintain the viscosity of the system at 4000mPa.s, evenly apply it on a PET film, and place it under a 2Kw ultraviolet lamp for 15 cm Cured for 50 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com