Degradable gel cool storage agent and preparation method thereof

The technology of a cold storage agent and gel is applied in the field of cold storage agent and its preparation, which can solve the problems of harming the earth environment and non-degradation, and achieve the effects of avoiding thermal damage, maintaining low temperature and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

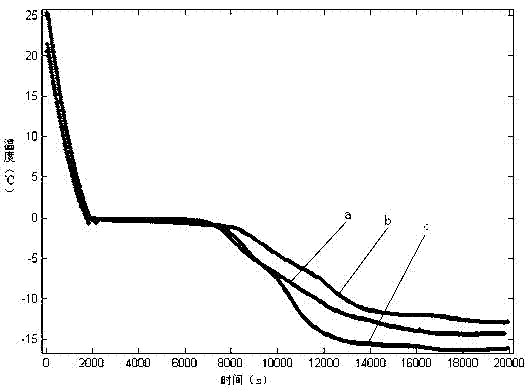

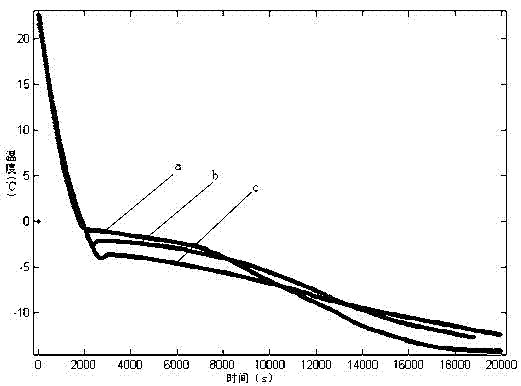

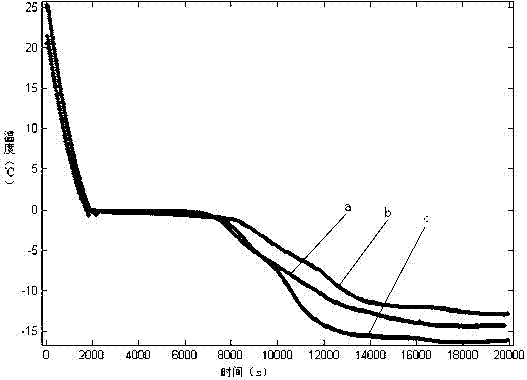

Image

Examples

Embodiment 1

[0022] Raw materials: dry starch is used to prepare a starch solution with a mass fraction of 11%; the initiator is ammonium persulfate, and the quality is 3% of the dry starch mass, and it is prepared into a 10wt% ammonium persulfate initiator solution; the crosslinking agent is N, N'-methylenebisacrylamide, the quality is 0.5% of the dry starch mass, prepared into 10wt% N,N'-methylenebisacrylamide crosslinking agent solution; use 25% NaOH solution to adjust the pH of acrylic acid To 6, the mass ratio of acrylic acid to dry starch before adjustment is 1.8:1.

[0023] Preparation process: When the temperature of the constant temperature water bath rises to 55°C, add the prepared starch solution into the four-necked flask, add the ammonium persulfate initiator solution, stir for 40 minutes and then add the acrylic acid solution and N, which have adjusted the pH. N'-methylenebisacrylamide cross-linking agent solution, stirring for graft copolymerization for 70 minutes. Dry in a...

Embodiment 2

[0026] Raw materials: dry starch is used to prepare a starch solution with a mass fraction of 11.76%; the initiator is ammonium persulfate, and the quality is 4% of the dry starch mass, and it is prepared into a 10wt% ammonium persulfate initiator solution; the crosslinking agent is N, N'-methylenebisacrylamide, the quality is 0.83% of the dry starch mass, prepared into 10wt% N,N'-methylenebisacrylamide crosslinking agent solution; use 25% NaOH solution to adjust the pH of acrylic acid To 6.5, the mass ratio of acrylic acid to dry starch before adjustment is 2:1.

[0027] Preparation process: When the temperature of the constant temperature water bath rises to 60°C, add the prepared starch solution into the four-neck flask, add the ammonium persulfate initiator solution, stir for 35 minutes and then add acrylic acid and N,N '-methylenebisacrylamide crosslinking agent solution, stirring for graft copolymerization for 1h. Dry in an oven at 60°C until constant weight, and pulver...

Embodiment 3

[0030] Raw materials: dry starch is used to prepare a starch solution with a mass fraction of 13%; the initiator is ammonium persulfate, and the quality is 5% of the dry starch mass, and it is prepared into a 10wt% ammonium persulfate initiator solution; the crosslinking agent is N, N'-methylenebisacrylamide, the quality is 1.5% of the dry starch mass, prepared into 10wt% N,N'-methylenebisacrylamide crosslinking agent solution; adjust the pH of acrylic acid with 25% NaOH solution To 7, the mass ratio of acrylic acid to dry starch before adjustment is 2.3:1.

[0031] Preparation process: When the temperature of the constant temperature water bath rises to 65°C, add the prepared starch solution into the four-neck flask, add the ammonium persulfate initiator solution, stir and initiate for 30 minutes, then add the acrylic acid solution with adjusted pH and N, N'-methylenebisacrylamide cross-linking agent solution, stirring for graft copolymerization for 50 minutes. Dry in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com